Abstract

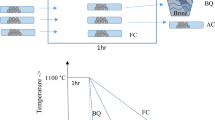

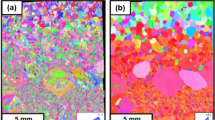

Plastic flow behavior and microstructure evolution during hot working and heat treatment of Ti-6Al-4V synthesized via a laser-deposition, Laser Engineered Net Shaping (LENSℳ), process were established. To this end, isothermal, hot compression tests were conducted on samples in either a deposited + stress relieved condition or a deposited + hot isostatically pressed (hipped) condition. The starting microstructures consisted of columnar grains with fine or coarse Widmanstätten (basketweave) alpha platelets. At subtransus temperatures, the flow curves of both microstructural conditions exhibited a peak stress at low strains followed by extensive flow softening; these curves were almost identical to previous measurements on ingot-metallurgy (IM) Ti-6Al-4V with similar transformed microstructures. In addition, the kinetics of globularization of the alpha phase during subtransus deformation or subsequent static heat treatment were found to be the same as for IM Ti-6Al-4V with comparable alpha-platelet thicknesses. During supertransus heat treatment, moderately fine beta-grain microstructures were developed in samples that had been predeformed below the beta transus. Such a heat treatment for samples previously deformed above the transus gave rise to a nonuniform distribution of coarse beta grains, an effect attributed to critical grain growth.

Similar content being viewed by others

References

S.L. Semiatin, V. Seetharaman, and I. Weiss: in Advances in the Science and Technology of Titanium Alloy Processing, I. Weiss, R. Srinivasan, P.J. Bania, D. Eylon, and S.L. Semiatin, eds., TMS, Warrendale, PA, 1997, pp. 3–73.

J.T. Schriempf, E.J. Whitney, P.A. Blomquist, and F.G. Arcella: in Advances in Powder Metallurgy and Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, 1997, vol. 3, pp. 21–31.

D.M. Keicher and W.d. Miller: in Carbides and Nitrides: Synthesis, Characterization, and Applications, TMS, Warrendale, PA, 1998, p. 369.

G.K. Lewis and E. Schlienger: Mater. Design, 2000, vol. 21, pp. 417–23.

S.L. Semiatin, V. Seetharaman, and I. Weiss: Mater. Sci. Eng. A, 1999, vol. A263, pp. 257–71.

E.B. Shell and S.L. Semiatin: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 3219–3329.

S.L. Semiatin and T.R. Bieler: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1787–99.

I. Weiss and S.L. Semiatin: Mater. Sci. Eng. A, 1999, vol. A243, pp. 46–65.

J.J. Jonas and H.J. McQueen: in Treatise on Materials Science and Technology, vol. 6, Plastic Deformation of Metals, R.J. Arsenault, ed., Academic Press, New York, NY, 1975, pp. 394–490.

N. Stefansson: Ph.D. Thesis, University of Dayton, Dayton, OH, 2000.

R.W. Cahn and P. Haasen: Physical Metallurgy, North-Holland, Amsterdam, 1996.

D.U. Furrer, E. Heinritz, and R.R. Boyer: Ladish Co., Inc., Cudahy, WI, unpublished research, 2000.

F.G. Arcella and F.H. Froes: JOM, 2000, vol. 52(5), pp. 28–30.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Semiatin, S.L., Kobryn, P.A., Roush, E.D. et al. Plastic flow and microstructure evolution during thermomechanical processing of laser-deposited Ti-6Al-4V preforms. Metall Mater Trans A 32, 1801–1811 (2001). https://doi.org/10.1007/s11661-001-0156-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0156-0