Abstract

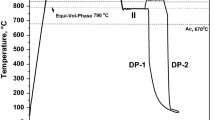

A series of high-martensite dual-phase (HMDP) steels exhibiting a 0.3 to 0.8 volume fraction of martensite (V m ), produced by intermediate quenching (IQ) of a vanadium and boron-containing microalloyed steel, have been studied for toughness and fatigue behavior to supplement the contents of a recent report by the present authors on the unusual tensile behavior of these steels. The studies included assessment of the quasi-static and dynamic fracture toughness and fatigue-crack growth (FCG) behavior of the developed steels. The experimental results show that the quasi-static fracturetoughness (K ICV ) increases with increasing V m in the range between V m =0.3 and 0.6 and then decreases, whereas the dynamic fracture-toughness parameters (K ID , K D , and J ID ) exhibit a significant increase in their magnitudes for steels containing 0.45 to 0.60 V m before achieving a saturation plateau. Both the quasi-static and dynamic fracture-toughness values exhibit the best range of toughnesses for specimens containing approximately equal amounts of precipitate-free ferrite and martensite in a refined microstructural state. The magnitudes of the fatigue threshold in HMDP steels, for V m between 0.55 and 0.60, appear to be superior to those of structural steels of a similar strength level. The Paris-law exponents (m) for the developed HMDP steels increase with increasing V m , with an attendant decrease in the pre-exponential factor (C).

Similar content being viewed by others

References

Dual-Phase and Cold Pressing Vanadium Steels in the Automobile Industry, Vanitec, Berlin, 1978.

Structure and Properties of Dual-Phase Steels, R.A. Kot and J.W. Morris, eds., AIME, New York, NY, 1979.

Formable HSLA and Dual-Phase Steels, A.T. Davenport, ed., AIME, New York, NY, 1979.

R.G. Davies and C.L. Magee: Dual-Phase and Cold Pressing Vanadium Steels in the Automobile Industry, Vanitec, Berlin, 1978, p. 25.

S. Kang and H. Kwon: Metall. Trans. A, 1987, vol. 18A, pp. 1587–92.

A. Bag, K.K. Ray, and E.S. Dwarakadasa: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1193–1202.

K.K. Ray and S. Ray: Proc. Int. Symp. on Fatigue and Fracture in Steel and Concreate Structures, A.G. Madhava Rao and T.V.S.R. Appa Rao, eds., Oxford and IBH, Delhi, 1991, pp. 317–32.

K.K. Ray, D. Chakraborty, and S. Ray: J. Mater. Sci., 1994, vol. 29, pp. 921–28.

Standard Designation E399-90, ASTM, Philadelphia, PA, 1993, vol. 03.01, pp. 509–39.

Standard Designation E561-92a, ASTM, Philadelphia, PA, 1993, vol. 03.01, pp. 600–11.

Standard Designation E813-89, ASTM, Philadelphia, PA, 1993, vol. 03.01, pp. 738–52.

Methods for “Crack Opening Displacement (COD) Testing,” BS 5762, British Standards Institute, 1979.

L.M. Barker: Eng. Fract. Mech., 1977, vol. 9, pp. 361–69.

J.C. Newman Jr.: in Chevron Notched Specimens: Testing and Stress Analysis, ASTM STP, 855, J.H. Under Wood, eds., ASTM, Philadelphia, PA, 1984, pp. 5–31.

Standard Designation E1304-89, ASTM, Philadelphia, PA, 1993, vol. 03.01, pp. 962–72.

K.K. Ray, Dipita Chakraborty, and S. Ray: Int. J. Fract., 1992, vol. 57, pp. R7-R11.

K.K. Ray, D. Chakraborty, and S. Ray: in Advances in Fracture Resistance and Structural Integrity, V.V. Panasyuk, D.M.R. Taplin, M.C. Pandey, O. Ye. Andreykiv, R.O. Ritchie, J.F. Knott, and P. Rama Rao, eds., Pergamon Press, 1994, pp. 569–74.

W.L. Server, D.R. Ireland, and R.A. Wullaert: Strength and Toughness Evolutions from an Instrumented Impact Test, TR 74-29R, Effects Technology, Inc., (Dynatup), CA, 1974.

K.L. Murty, R.P. Shogan, and W.H. Bamford: Nucl. Technol., 1984, vol. 64, pp. 268–74.

R.O. Ritchie: Int. Metall. Rev., 1979, vol. 20, pp. 205–30.

R.O. Ritichie and S. Suresh: Metall. Trans. A, 1982, vol. 13A, pp. 937–40.

G.T. Grey, F.W. Thompson, and J.C. Williams: Metall. Trans. A, 1983, vol. 14A, pp. 421–33.

V.V. Dutta, S. Suresh, and R.O. Ritchie: Metall. Trans. A, 1984, vol. 15A, pp. 1193–1207.

K. Minakawa, Y. Matsuo, and A.J. McEvily: Metall. Trans. A, 1982, vol. 13A, pp. 439–45.

H. Suzuki and A.J. McEvily: Metall. Trans. A, 1979, vol. 10A, pp. 475–81.

J.A. Wasynczuk, R.O. Ritchie, and G. Thomas: Mater. Sci. Eng., 1984, vol. 62, pp. 79–92.

T. Kunio and K. Yamada: in Fatigue Mechanisms, ASTM STP 675, J.T. Fong, ed., ASTM, Philadelphia, PA, 1979, pp. 342–70.

A. Bag: Ph.D. Dissertation, IIT, Kharagpur, India, 1996.

Standard Designation E647-93, ASTM, Philadelphia, PA, 1993, vol. 03.01, pp. 679–706.

Wu Shang-Xian: in Chevron Notched Specimens: Testing and Stress Analysis, ASTM STP 855, J.H. Underwood, S.W. Freiman, and F.I. Baratta, eds., ASTM, Philadelphia, PA, 1984, pp. 176–92.

J.F. Knott: Fundamentals of Fracture Mechanics, Butterworth and Co., London, 1973.

P.C. Paris: Fatigue—An Interdisciplinary Approach, Proc. 10th Sagamore Conf., Syracuse University Press, Syracuse, NY, 1964, pp. 107–27.

L.M. Barker: in Chevron Notched Speciments: Testing and Stress Analysis, ASTM STP 855, J.H. Under Wood, S.W. Freiman, and F.I. Baratta, eds., ASTM, Philadelphia, PA, 1984, pp. 117–33.

Y.S. Zheng, Z.G. Wang, and S.H. Ai: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 1713–23.

R.W. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, John Wiley & Sons, Singapore, 1989, p. 545.

L.P. Pook: J. Strain Analysis, 1975, vol. 10, pp. 242–50.

D.L. Chen, Z.G. Wang, X.X. Jiang, S.H. Ai, and C.H. Shih: in Basic Mechanisms in Fatigue of Metals, Materials Science Monographs 46, P. Lukáš and J. Polák, eds., Elsevier, Amsterdam, 1988, pp. 351–59.

J.H. Bulloch and R.O. Kennedy: Res. Mechanica, 1985, vol. 15, pp. 259–74.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bag, A., Ray, K.K. & Dwarakadasa, E.S. Influence of martensite content and morphology on the toughness and fatigue behavior of high-martensite dual-phase steels. Metall Mater Trans A 32, 2207–2217 (2001). https://doi.org/10.1007/s11661-001-0196-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0196-5