Abstract

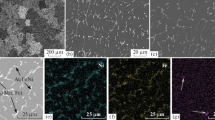

A commercial aluminum alloy, 5083, was processed using a cryomilling synthesis approach to produce powders with a nanostructured grain size. The powders were subsequently degassed, hot isostatically pressed, and extruded. The grain size at each processing step was measured utilizing both X-ray diffraction and transmission electron microscopy (TEM). The mechanical properties of the n-5083 extruded material were determined utilizing ASTM E8-93, Standard Test Methods for Tension Testing of Metallic Materials. This processing technique was found to produce a thermally stable nanostructured aluminum alloy which maintained an average grain size of 30 to 35 nm through several processing steps up to 0.61 T mp . The thermal stability was attributed to Zener pinning of the grain boundaries by AIN and Al2O3 particles and solute drag of numerous atomic species. The nanostructured 5083 was found to have a 30 pct increase in yield strength and ultimate strength over the strongest commercially available form of 5083, with no corresponding decrease in elongation. The enhanced ductility is attributed to the presence of a few large, single-crystal aluminum grains acting as crack-blunting objects.

Similar content being viewed by others

References

G.W. Nieman, J.R. Weertman, and R.W. Siegel: J. Mater. Res., 1991, vol. 6, p. 1012.

K. Higashi, A. Uoya, T. Mukai, S. Tanimura, A. Inoue, T. Masumoto, and K. Ohtera: Mater. Sci. Eng., 1994, vols. A181–A182, p. 1068.

G.T. Gray III, T.C. Lowe, C.M. Cady, R.Z. Valiev, and I.V. Aleksandrov: Nanostr. Mater., 1997, vol. 9, p. 477.

H. Gleiter: Nanostr. Mater., 1995, vol. 6, p. 3.

M.N. Rittner and T. Abraham: JOM, 1998, vol. 1, p. 36.

M.V. Markushev, C.C. Bampton, M.Y. Murashkin, and D.A. Hardwick: Mater. Sci. Eng., 1997, vols. A234–A236, p. 927.

J. Wang, Z. Horita, M. Furukawa, M. Nemoto, N. Tsenev, R. Valiev, Y. Ma, and T. Langdon: J. Mater. Res., 1993, vol. 8, p. 2810.

T. Mukai, M. Kawazoe, and K. Higashi: Mater. Sci. Eng., 1998, vol. A247, p. 270.

M. Mabuchi, H. Iwasaki, and K. Higashi: Nanostr. Mater., 1997, vol. 8, p. 1105.

M.J. Luton, C.S. Jayanth, M.M. Disko, S. Matras, and J. Vallone: Mater. Res. Soc. Symp. Proc., 1989, vol. 132, p. 79.

R.J. Perez, B. Huang, and E.J. Lavernia: Nanostr. Mater., 1996, vol. 7, p. 565.

B.D. Cullity: Elements of X-ray Diffraction, Addison-Wesley, Cambridge, MA, 1978, p. 101.

M.K. Miller, A. Cerezo, M.G. Hetherington, and G.D.W. Smith: Atom Probe Field Ion Microscopy, Clarendon Press, Oxford, United Kingdom, 1996.

C.E. Krill and R. Birringer: Phil. Mag. A, 1998, vol. 77, p. 621.

J.R. Davis: ASM Specialty Handbook—Aluminum and Aluminum Alloys, ASM INTERNATIONAL, Materials Park, OH, 1994, p. 675.

E.A. Brandes: Smithell’s Metals Reference Book, Butterworth-Heinemann, London, 1992.

O. Susegg, E. Hellum, A. Olsen, and M.J. Luton: Phil. Mag. A, 1993, vol. 68, p. 367.

R.J. Perez, H.G. Jiang, C.P. Dogan, and E.J. Lavernia: Metall. Trans. A, 1998, vol. 29A, pp. 2469–75.

V.L. Tellkamp, S. Dallek, D. Cheng, and E.J. Lavernia: University of California, Irvine, CA, unpublished research, 2000.

J.P. Hirth and J. Lothe: Theory of Dislocations, John Wiley & Sons, New York, NY, 1982, p. 788.

T. Mukai, K. Ishikawa, and K. Higashi: Mater. Sci. Eng., 1995, vol. A204, p. 12.

V.G. Gryaznov and L.I. Trusov: Progr. Mater. Sci., 1993, vol. 37, p. 289.

H. Gleiter: Progr. Mater. Sci., 1989, vol. 33, p. 223.

J.R. Weertman, D. Farkas, K. Hemker, H. Kung, M. Mayo, R. Mitra, and H. Van Swygenhoven: MRS Bull., 1999, vol. 2, p. 44.

T.R. Malow and C.C. Koch: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2285–95.

R.Z. Valiev and I.V. Alexandrov: Nanostr. Mater., 1999, vol. 12, p. 35.

P.G. Sanders, C.J. Youngdahl, and J.R. Weertman: Mater. Sci. Eng., 1997, vol. A234, p. 77.

D. Ponge, M. Bredehoft, and G. Gottstein: Scripta Mater., 1997, vol. 37, p. 1769.

N. Wang, Z. Wang, K.T. Aust, and U. Erb: Mater. Sci. Eng., 1997, vol. A237, p. 150.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tellkamp, V.L., Lavernia, E.J. & Melmed, A. Mechanical behavior and microstructure of a thermally stable bulk nanostructured Al alloy. Metall Mater Trans A 32, 2335–2343 (2001). https://doi.org/10.1007/s11661-001-0207-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0207-6