Abstract

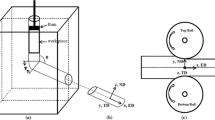

Two grades of low-carbon steel, one containing vanadium and the other without vanadium, were subjected to equal channel angular pressing (ECAP) at 623 K up to an effective strain of ∼4. After equal channel angular pressing, a static annealing treatment for 1 hour was undertaken on both pressed steels in the temperature range of 693 to 873 K. By comparing the microstructural evolution during annealing and the tensile properties of the two steels, the effect of the addition of vanadium on the thermal stability of ultrafine-grained (UFG) low-carbon steel fabricated by intense plastic straining was examined. For the steel without vanadium, coarse recrystallized ferrite grains appeared at annealing temperatures above 753 K, and a resultant degradation of the strength was observed. For the steel containing vanadium, submicrometer-order ferrite grain size and ultrahigh strength were preserved up to 813 K. The enhanced thermal and mechanical stabilities of the steel containing vanadium were attributed to its peculiar microstructure, which consisted of ill-defined pearlite colonies and ultrafine ferrite grains with uniformly distributed nanometer-sized cementite particles. This microstructure resulted from the combined effects of (a) the preservation of high dislocation density providing an effective diffusion path, due to the effect of vanadium on increasing the recrystallization temperature of the steel; and (b) precipitation of fine cementite particles at ferrite grain boundaries through the enhanced diffusion of carbon atoms (which were dissolved from pearlitic cementite by severe plastic straining) along ferrite grain boundaries and dislocation cores.

Similar content being viewed by others

References

V.M. Segal, V.I. Reznikov, A.D. Drobyshevskiy, and V.I. Kopylov: Russ. Metall., 1981, vol. 1, pp. 99–105.

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong: Scripta Mater., 1998, vol. 39, pp. 1221–27.

R.V. Valiev, F. Chmelik, F. Bordeaux, G. Kapelski, and B. Baudelet: Scripta Metall. Mater., 1992, vol. 27, pp. 855–60.

Z. Horita, D.J. Smith, M. Furukawa, M. Nemoto, R.Z. Valiev, and T.G. Langdon: J. Mater. Res., 1996, vol. 11, pp. 1880–90.

D.H. Shin, C.W. Seo, J. Kim, K.-T. Park, and W.Y. Choo: Scripta Mater., 2000, vol. 42, pp. 695–99.

D.H. Shin, B.C. Kim, Y.-S. Kim, and K.-T. Park: Acta Mater., 2000, vol. 48, pp. 2247–75.

D.H. Shin, B.C. Kim, K.-T. Park, and W.Y. Choo: Acta Mater., 2000, vol. 48, pp. 3245–52.

K.-T. Park, Y.S. Kim, J.K. Lee, and D.H. Shin: Mater. Sci. Eng., 2000, vol. A293, pp. 165–72.

T. Gladman: in The Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, 1997, pp. 213–61.

V.M. Segal: Mater. Sci. Eng., 1995, vol. A197, pp. 157–64.

M. Furukawa, Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Mater. Sci. Eng., 1998, vol. A257, pp. 328–32.

M. Nemoto, Z. Horita, M. Furukawa, and T.G. Langdon: Met. Mater., 1998, vol. 4, pp. 1181–90.

R.W.K. Honeycomb: Trans. AIME, 1976, vol. 7A, p. 915.

T. Gladman: in Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, 1997, p. 193.

F.B. Pickering: Physical Metallurgy and Design of Steel, Applied Science Publishers Ltd., London, 1978, pp. 15–20.

C. Garcia-Mateo, B. Lopez, and J.M. Rodriguez-Ibabe: Scripta Mater., 2000, vol. 42, pp. 137–43.

C. Garcia-Mateo, B. Lopez, and J.M. Rodriguez-Ibabe: Mater. Sci. Eng., 2001, vol. A303, pp. 216–25.

J.G. Speer, S. Mehta, and S.S. Hansen: Scripta Metall., 1984, vol. 18, pp. 1241–44.

K.J. Irvine, F.B. Pickering, and T. Gladman: J. Iron Steel Inst., 1967, vol. 205, p. 563.

K. Narita: Trans. Iron Steel Inst. Jpn., 1975, vol. 15, p. 145.

T. Gladman: Proc. R. Soc. A., 1966, vol. 294, p. 298.

C.S. Pande: Acta Metall., 1987, vol. 35, pp. 2671–78.

J. Languillaume, G. Kapelski, and B. Baudelet: Acta Mater., 1997, vol. 45, pp. 1201–12.

H.G. Read, W.T. Reynolds, Jr., K. Hono, and T. Tauri: Scripta Mater., 1997, vol. 37, pp. 1221–30.

F. Danoix, D. Julian, X. Saurage, and J. Copreaux: Mater. Sci. Eng., 1998, vol. A250, pp. 8–13.

K. Kamber, D. Keeter, and C. Wart: Acta Metall., 1961, vol. 9, pp. 403–14.

D. Kalish and M. Kohen: Mater. Sci. Eng., 1970, vol. 6, p. 156.

M.H. Hong, W.T. Reynolds, Jr., T. Tauri, and K. Hono: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 717–27.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Park, KT., Kim, YS. & Shin, D.H. Microstructural stability of ultrafine grained low-carbon steel containing vanadium fabricated by intense plastic straining. Metall Mater Trans A 32, 2373–2381 (2001). https://doi.org/10.1007/s11661-001-0211-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0211-x