Abstract

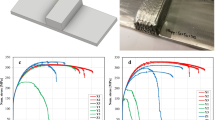

The AA5083 (Al-4.4Mg-0.7Mn-0.15Cr) alloy is a nonheat-treatable aluminum alloy known for its excellent corrosion resistance. However, it can become susceptible to intergranular stress corrosion cracking (IGSCC) when exposed to temperatures ranging from 50 °C to 200 °C for sufficient lengths of time. This IGSCC is widely believed to be associated with dissolution of the electrochemically active β phase, Al3Mg2, which is precipitated on grain boundaries. Recently, alternative mechanisms have been invoked related to hydrogen effects and/or free Mg segregation or depletion in the grainboundary regions. To establish a baseline for the sensitization effect, constant-extension-rate tests (CERTs) were conducted under open-circuit conditions and under potential control in 3.5 pct NaCl on samples isothermally treated at 150 °C. To aid in interpreting the CERT results, grain-boundary precipitation and solute depletion were characterized by transmission electron microscopy (TEM). Additionally, the electrochemical behavior of the β phase was characterized by anodic polarization of the intermetallic compound synthesized in bulk form. In CERTs under open-circuit conditions, the measured ductility depended strongly on sensitization time, reaching a minimum at 189 hours, followed by a slight increase at longer times. This trend correlated well with the fractional coverage of β phase on grain boundaries, which increased up to 189 hours, where it existed with nearly continuous coverage. At longer times, this film coarsened and became discontinuous. Correspondingly, some resistance to IGSCC was recovered. In polarization experiments, bulk synthesized β phase was found to be spontaneously passive from its corrosion potential (−1.40 VSCE) up to about −0.92 VSCE, where passivity was observed to break down. Sensitized AA5083 samples polarized below the β-phase breakdown potential showed almost no evidence of IGSCC, indicating that a high β dissolution rate is a requirement for IGSCC. Mg-depleted zones were observed along grain boundaries in sensitized alloys, but a clear role for solute depletion in IGSCC could not be defined on the basis of the results developed in this study.

Similar content being viewed by others

References

E.H. Dix, W.A. Anderson, and M.B. Shumaker: Corrosion, 1959, vol. 15 (2), pp. 19–26.

J.R. Pickens, J.R. Gordon, and J.A.S. Green: Metall. Trans. A, 1983, vol. 14A, pp. 925–30.

J.R. Pickens, T.J. Langan, and J.A.S. Green: ONR End of the Year Report. No. N000014-81-C0380 R.P. Wei, D.J. Duquette, T.J. Crooker, and A.J. Sedriks, eds., Martin Marietta Corporation, Washington, DC, June 1985, pp. 115–31.

H. Yukawa, Y. Murata, M. Morinaga, Y. Takahashi, and H. Yoshida: Acta Metall. Mater., 1995, vol. 43, pp. 681–88.

P. Doig and J.W. Edington: Proc. R. Soc. A, 1974, vol. 339, pp. 37–47.

D.R. Baer, C.F. Windisch, M.H. Englehard, M.J. Danielson, R.H. Jones, and J.S. Vetrano: J. Vacuum Sci. Technol. A, 2000, vol. 18, pp. 131–36.

R.C. Newman and R.P.M. Proctor: Br. Corr. J., 1990, vol. 25, pp. 259–69.

V.V. Cherkasov, L.G. Korneleyuk, P.P. Pobezhimov, and L.P. Nefedova: translated from Metall. Term. Obrabotke Metallov., 1992, vol. 12, pp. 24–26.

A. Barbucci, P.L. Cabot, G. Bruzzone, and G. Cerisola: J. Alloys Compounds, 1998, vol. 268, pp. 295–301.

R. Braun and T. Hack: Mater. Sci. Forum, 1996, vol. 217, pp. 1635–40.

J. Hirsch: Mater. Sci. Forum, 1997, vol. 242, pp. 33–50.

J.C. Chang and T.H. Chuang: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 3191–99.

M.C. Carroll, P.I. Gouma, G.S. Daehn, M.J. Mills, and B.R. Dunbar: Scripta Mater., 2000, vol. 42, pp. 335–40.

Aluminum Standards and Data, The Aluminum Association, Inc., Washington, DC, 1997, p. 2–1.

CRC Handbook of Chemistry and Physics, 67th ed., R.C. Weast, ed., CRC Press, Boca Raton, FL, 1987, p. E42.

D.O. Sprowls and R.H. Brown: in Fundamental Aspects of Stress Corrosion Cracking, Conf. Proc., R.W. Staehle, and A.J. Forty, eds., National Association of Corrosion Engineers, Houston, TX, 1969, pp. 466–512.

T. Mae, Ihara, K. Komura, S. Toriyama, S. Sunada, and K. Arai: Mater. Trans. JIM, 1996, vol. 37, pp. 1781–88.

G.M. Scamans, N.J.H. Holroyd, and C.D.S. Tuck: Corr. Sci., 1987, vol. 27, pp. 329–47.

N.J.H. Holroyd and G.M. Scamans: Scripta Metall., 1985, vol. 19, pp. 915–16.

A.F. Beck and P.R. Sperry: Fundamental Aspects of Stress Corrosion Cracking, Proc. Conf., R.W. Staehle and A.J. Forty, eds., National Association of Corrosion Engineers, Houston, TX, 1969, pp. 513–29.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Searles, J.L., Gouma, P.I. & Buchheit, R.G. Stress corrosion cracking of sensitized AA5083 (Al-4.5Mg-1.0Mn). Metall Mater Trans A 32, 2859–2867 (2001). https://doi.org/10.1007/s11661-001-1036-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-1036-3