Abstract

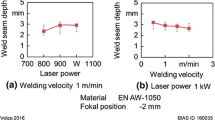

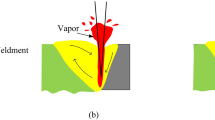

This article presents the simulation results of a three-dimensional mathematical model using the level set method for laser-keyhole welding. The details of the model are presented in Part I.[4] The effects of keyhole formation on the liquid melt pool and, in turn, on the weld bead are investigated in detail. The influence of process parameters, such as laser power and scanning speed is analyzed. This simulation shows very interesting features in the weld pool, such as intrinsic instability of keyholes, role of recoil pressure, and effect of beam scanning.

For verification purposes, visualization experiments have been performed to measure melt-pool geometry and surface velocity. The theoretical predictions show a reasonable agreement with the experimental observations.

Similar content being viewed by others

References

I. Currie: Fundamental Mechanics of Fluids, 2nd ed. McGraw-Hill, Singapore, 1993.

S. Fujinaga, H. Takenaka, T. Narikiyo, S. Katayama, and A. Matsunawa: J. Phys. D: Appl. Phys., 2000, vol. 33, pp. 492–97.

H. Ki, P. Mohanty, and J. Mazumder: filed for U.S. Patent, 2001.

H. Ki, P.S. Mohanty, and J. Mazumder: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1817–30.

L. Landau and E. Lifshitz: Fluid Mechanics, 2nd ed., Pergamon Press, Singapore, 1989.

A. Matsunawa: Keyhole Dynamics in Laser Welding, Technical Report, Lecture Note from a Course Given at ICALEO, San Diego, CA, 1999.

A. Matsunswa and V. Semak: J. Phys. D: Appl. Phys., 1997, vol. 30, pp. 798–809.

J. Mazumder: Opt. Eng., 1991, vol. 30 (8), pp. 1208–19.

V.V. Semak, W.D. Bragg, B. Damkroger, and S. Kempka: J. Phys. D: Appl. Phys., 1999, vol. 32, pp. L61-L64.

W.M. Steen: Laser Material Processing, 2nd ed., Springer, London, 1998.

D.D. Voelkel and J. Mazumder: U.S. Patent 5,446,549, Aug. 1995.

R.L. Zehr: Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, 1991.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ki, H., Mazumder, J. & Mohanty, P.S. Modeling of laser keyhole welding: Part II. simulation of keyhole evolution, velocity, temperature profile, and experimental verification. Metall Mater Trans A 33, 1831–1842 (2002). https://doi.org/10.1007/s11661-002-0191-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0191-5