Abstract

In the present study, the relationships between the structure and properties of a cryomilled Al-7.5 pct Mg alloy were investigated. The microstructure of the cryomilled Al-7.5 pct Mg alloy consisted of equiaxed grains with an approximate size of 300 nm. Thermal treatment had only a minor effect on microstructure, as evidenced by X-ray diffraction (XRD) and transmission electron microscopy (TEM) results. The tensile behavior was characterized by high strength, high ductility, and low-strain-hardening. The tensile deformation was relatively uniform, with limited necking deformation, and fracture surfaces were characterized by microdimples. The variation of strain rates from 4 · 10−4 to 4 · 10−2 s−1 had an insignificant effect on tensile behavior. Comparison of compressive and tensile behavior revealed similar moduli and yield strengths, although the postyield behavior was markedly asymmetric. The present results indicate that grain-size effects, solid-solution strengthening, Orowan strengthening, and dislocation strengthening contribute significantly to the properties of a cryomilled Al-7.5 pct Mg alloy.

Similar content being viewed by others

References

H. Gleiter: Progr. Mater. Sci., 1989, vol. 33, pp. 223–315.

C. Suryanarayana: Int. Mater. Rev., 1995, vol. 40, pp. 41–64.

P.G. Sanders, J.A. Eastman, and J.R. Weertman: Acta Mater., 1997, vol. 45, pp. 4019–25.

A.M. Elsherik and U. Erb: J. Mater. Sci., 1995, vol. 30, pp. 5743–49.

R. Birringer: Mater. Sci. Eng., 1989, vol. A117, pp. 33–43.

K. Lu: Mater. Sci. Eng., 1996, vol. R16, pp. 161–221.

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Progr. Mater. Sci., 2000, vol. 45, pp. 103–89.

V.L. Tellkamp, A. Melmed, and E.J. Lavernia: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2335–43.

L. Lu, L.B. Wang, B.Z. Ding, and K. Lu: J. Mater. Res., 2000, vol. 15, pp. 270–73.

W.M. Yin, S.H. Whang, R. Mirshams, and C.H. Xiao: Mater. Sci. Eng., 2001, vol. A 301, pp. 18–22.

D. Jia, Y.M. Wang, K.T. Ramesh, E. Ma, Y.T. Zhu, and R.Z. Valiev: Appl. Phys. Lett., 2001, vol. 79, pp. 611–13.

R. Rodriguez, R.W. Hayes, and E.J. Lavernia: Acta Mater., 2002, in press.

R.W. Hayes, R. Rodriguez, and E.J. Lavernia: Acta Mater., 2001, vol. 49, pp. 4055–68.

X.K. Sun, H.T. Cong, M. Sun, and M.C. Yang: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1017–24.

M. Jain and T. Christman: Acta Metall., 1994, vol. 42, pp. 1901–11.

J.E. Carsley, A. Fisher, W.W. Milligan, and E.C. Aifantis: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2261–71.

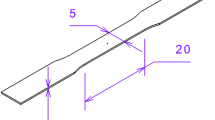

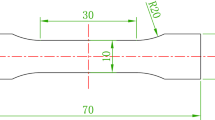

1999 Annual Book of ASTM Standards, West Conshohocken, PA, 1999, pp. 99–106.

M.A. Meyers and K.K. Chawla: Mechanical Metallurgy Principles and Applications, Prentice-Hall, Englewood Cliffs, NJ, 1984.

B.Q. Han and D.C. Dunand: Mater. Sci. Eng., 2000, vol. A277, pp. 297–304.

J. Benedict, R. Anderson, and S.J. Klepeis: Materials Research Society Symposia, Materials Research Society, Pittsburgh, PA, 1992, pp. 121–40.

F. Zhou, R. Rodriguez, and E.J. Lavernia: Mater. Sci. Forum, 2002, vols. 386–388, pp. 409–14.

T. Mukai, K. Ishikawa, and K. Higashi: Mater. Sci. Eng., 1995, vol. A204, pp. 12–18.

G.T. Gray III, T.C. Lowe, C.M. Cady, R.Z. Valiev, and I.V. Aleksandrov: NanoStruct. Mater., 1997, vol.9, pp. 477–80.

T. Mukai, M. Kawazoe, and K. Higashi: Mater. Sci. Eng., 1998, vol. A247, pp. 270–74.

D. Jia, K.T. Ramesh, and E. Ma: Scripta Mater., 2000, vol. 42, pp. 73–78.

S.L. Semiatin, K.V. Jata, M.D. Uchic, P.B. Berbon, D.E. Matejezyk, and C.C. Bampton: Scripta Mater., 2001, vol. 44, pp. 395–400.

D. Jia, K.T. Ramesh, E. Ma, L. Lu, and K. Lu: Scripta Mater., 2001, vol. 45, pp. 613–20.

Z. Lee, R. Rodriguez, E.J. Lavernia, and S.R. Nutt: Ultrafine-Grained Materials II, Seattle, WA, Y.T. Zhu, T.G. Langdon, R.S. Mishra, S.L. Semiatin, M.J. Saran, and T.C. Lowe, eds., TMS, Warrendale, PA, 2002, pp. 653–59.

ASM Handbook: Alloy Phase Diagrams, ASM, Metals Park, OH, 1992.

F. Zhou, K.H. Chung, and E.J. Lavernia: in Powder Metallurgy Alloys and Particulate Materials for Industrial Application, A.E. Alman and J.W. Newkirk, eds., TMS, Warrendale, PA, 2000, pp. 167–77.

D.L. Zhang, T.B. Massalski, and M.R. Paruchuri: Metall. Mater. Trans. A, 1994, vol. 25, pp. 73–79.

F. Zhou, J. Lee, S. Dallek, and E.J. Lavernia: J. Mater. Res., 2001, vol. 16, pp. 3451–58.

F. Zhou, J. Lee, and E.J. Lavernia: Scripta Mater., 2001, vol. 44, pp. 2013–17.

I.C. Barlow, H. Jones, and W.M. Rainforth: Acta Mater., 2001, vol. 49, pp. 1209–24.

K.I. Moon, H.S. Park, and K.S. Lee: J. Alloys Compounds, 2001, vol. 325, pp. 236–44.

V.L. Tellkamp, S. Dallek, D. Cheng, and E.J. Lavernia: J. Mater. Res., 2001, vol. 16, pp. 938–44.

T.H. Courtney: Mechanical Behavior of Materials, 2nd ed., McGraw-Hill Higher Education, New York, NY, 2000.

M.J. Luton, C.S. Jayanth, M.M. Disko, S. Matras, and J. Vallone: Materials Research Society Symposia Proceedings, Materials Research Society, Pittsburgh, PA, 1989, pp. 79–86.

O. Susegg, E. Hellum, A. Olsen, and M.J. Luton: Phil. Mag. A, 1993, vol. 68, pp. 367–80.

L.M. Brown and R.K. Ham: in Strengthening Methods in Crystals, A. Kelly and R.B. Nicholson, eds., Elsevier, Amsterdam, 1971, pp. 9–135.

X.Z. Liao, J.Y. Huang, Y.T. Zhu, F. Zhuo, and E.J. Lavernia: Ultrafine-Grained Materials II, Seattle, WA, Y.T. Zhu, T.G. Langdon, R.S. Mishra, S.L. Semiatin, M.J. Saran, and T.C. Lowe eds., TMS, Warrendale, PA, 2002, pp.323–30.

R.W. Siegel and G.E. Fougere: NanoStruct. Mater., 1995, vol. 6, pp. 205–16.

D.J. Lloyd and L.R. Morris: Acta Metall., 1977, vol. 25, pp. 857–61.

D.J. Lloyd: Met. Sci., 1980, vol. May, pp. 193–98.

J.M. Robinson: Int. Mater. Rev., 1994, vol. 39, pp. 217–27.

F.A. Mohamed, K.L. Murty, and T.G. Langdon: Acta Metall., 1974, vol. 22, pp. 325–32.

P. Hahner: Acta Mater., 1997, vol. 45, pp. 3695–707.

B. Russell: Phil. Mag., 1963, vol. 8, pp. 615–30.

J.W. Christian and S. Mahajan: Progr. Mater. Sci., 1995, vol. 39, pp. 1–157.

G.T. Gray III: Acta Metall., 1988, vol. 36, pp. 1745–54.

E. El-Danaf, S.R. Kalidindi, and R.D. Doherty: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1223–33.

D.E. Matejcyzk and C.C. Bampton: unpublished data on cryomilled nanostructured Al-7.5 pct Mg, 2002, Canoga Park, CA.

T. Mukai, M. Kawazoe, and K. Higashi: NanoStruct. Mater., 1998, vol. 10, pp. 755–65.

S.Y. Chang, J.G. Lee, K.T. Park, and D.H. Shin: Mater. Trans., 2001, vol. 42, pp. 1074–80.

T. Hasegawa, T. Miura, T. Takahashi, and T. Yakou: Iron Steel Inst. Jpn. Int., 1992, vol. 32, pp. 902–08.

E. Ma: Powder Metall., 2000, vol. 43, pp. 306–10.

R.Z. Valiev, E.V. Kozlov, Y.F. Ivanov, J. Lian, A.A. Nazarov, and B. Baudelet: Acta Metall. Mater., 1994, vol. 42, pp. 2467–75.

S. Hariprasad, S.M.L. Sastry, and K.L. Jerina: Acta Mater., 1996, vol. 44, pp. 383–89.

C.J. Youngdahl, J.R. Weertman, R.C. Hugo, and H.H. Kung: Scripta Mater., 2001, vol. 44, pp. 1475–78.

M. Legros, B.R. Elliott, M.N. Rittner, J.R. Weertman, and K.J. Hemker: Phil. Mag. A, 2000, vol. 80, pp. 1017–26.

Z. Horita, T. Fujinami, and T.G. Langdon: Mater. Sci. Eng., 2001, vol. A318, pp. 34–41.

M.N. Rittner, J.R. Weertman, J.A. Eastman, K.B. Yoder, and D.S. Stone: Mater. Sci. Eng., 1997, vol. A237, pp. 185–90.

D. Kuhlmann-Wilsdorf: Mater. Sci. Forum, 2000, vols. 331–337, pp. 689–702.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Han, B.O., Mohamed, F.A., Lee, Z. et al. Mechanical properties of an ultrafine-grained Al-7.5 Pct Mg alloy. Metall Mater Trans A 34, 603–613 (2003). https://doi.org/10.1007/s11661-003-0095-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-003-0095-z