Abstract

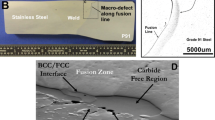

This study investigates the microstructure and fracture behavior of dissimilar weldments of alloy 690 and SUS 304L for various additions of niobium (0.1, 1.03, 2.49, and 3.35 wt pct) in the flux. With identical parameters and procedures, weldments were butt welded by the shielding metal arc welding (SMAW) process using three layers, with each layer being deposited in a single pass. The results indicate that the microstructure of the fusion zone was primarily dendritic and that the contents of Ni, Cr, and Fe within this zone remain relatively constant and resemble alloy 690. With Nb addition, it is noted that the microstructure changes from a cellular to columnar dendrite and equiaxed dendrite. Meanwhile, the dendrite arm spacing reduces and the secondary arms grow longer. Moreover, the composition of the interdendritic phase, whose precipitate volume percentage increases from 5 to 25 pct, changes from Al-Ti-O to Nb rich. The spread of the interdendritic phase is less in the root bead than in the cap bead due to the greater influence of base metal dilution in this region. Mechanical tests indicate that Nb addition increases the average hardness of the weldment and reduces its elongation prior to rupture. However, the tensile strength is essentially unchanged by Nb addition. It is found that the average hardness of the root bead is generally lower than the cap bead, and that the tensile specimens all rupture in the fusion zone, with the fracture surfaces exhibiting ductile features. It is noted that the cap bead tends to rupture interdendritically with increasing Nb addition. Finally, fractography shows that the dimples in the root become larger and shallower with Nb addition and are rich with an interdendritic phase.

Similar content being viewed by others

References

INCONEL 690, Huntington Alloys Inc., Huntington, WV, 1980.

B.P. Miglin and L.W. Sarner: Report No. NP-3957M, Electric Research Institute, Palo Alto, CA, 1985.

G.J. Theus, R.H. Emanuelson, and S.F. Chou: Report No. NP-3061, Electric Research Institute, Palo Alto, CA, 1983.

H. Nagano, K. Yamanaka, K. Kobayashi, and M. Inoue: Sumitomo Met., 1988, vol. 40 (4), pp. 17–28.

C.M. Brown and W.J. Mills: Corrosion, 1999, vol. 55 (2), pp. 173–86.

Z. Fang and R. W. Staehle: Corrosion, 1999, vol. 55 (4), pp. 355–79.

W.U. Wu and C.H. Tsai: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 417–26.

H.T. Lee and T.Y. Kuo: Sci. Technol. Welding Joining, 1999, vol. 4 (2), pp. 94–03.

H.T. Lee, T.Y. Kuo, C.J. Tu, D.C. Yeh, and S.L. Jeng: J. Chin. Soc. Mech. Eng., 1999, vol. 20 (3), pp. 277–84.

H.T. Lee and T.Y. Kuo: Sci. Technol. Welding Joining, 1999, vol. 4 (4), pp. 246–56.

K. Yamanaka, K. Ogawa, K. Kobayashi, S. Nagata, and T. Minami: The Sumitomo Search, 1993, vol. 51, pp. 1–15.

H.K. Uno, A. Kimura, and T. Misawa: The Sumitomu Search, 1993, vol. 54, pp. 48–55.

Metals Handbook, 10th ed., ASM, Materials Park, OH, 1990, vol. 2, pp. 428–45.

B.E. Payne: Met. Construction, 1969, vol. 1, pp. 79–88.

Welding Products, Advertising Brochure, Inco Alloys International Welding Products Co., Huntington, WV, 1993, pp. 1–13.

R. T. Holt and W. Wallace: International Metals Reviews, 1976, March, pp. 1–24.

H.T. Lee and S.L. Jeng: Sci. Technol. Welding Joining, 2001, vol. 6 (4), pp. 225–34.

J.C. Thornley: Welding J., 1973, vol. 52, pp. 355s-364s.

H.T. Lee, D.C. Yeh, S.L. Jeng, and T.Y. Kuo: Chin. Met. Heat Treatment, 2000, vol. 64, pp. 28–39 (in Chinese).

W.F. Savage, E.F. Nippes, and G.M. Goodwin: Welding J., 1977, vol. 56, pp. 245s-253s.

M.J. Cieslak, T.J. Headly, T. Kolle, and A.D. Romig: Metall. Trans. A, 1988, vol. 19A, pp. 2319–31.

W. Kurz and D.J. Fisher: Fundamentals of Solidification, Trans Tech Publications Ltd., Aedermannsdorf, Switzerland, 1992, pp. 15–16.

S. Kuo: Welding Metallurgy, 1st ed., Wiley, New York, NY, 1987, pp. 129–36.

J.N. Dupont, C.V. Robino, J.R. Michael, M.R. Nois, and A.R. Marder: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2785–96.

J.N. Dupont, C.V. Robino, J.R. Michael, A.R. Marder, and M.R. Nois: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2797–06.

I. Gowrisankar, A.K. Bhaduri, V. Seetharaman, D.D.N. Verma, and D.R.G. Achar: Welding J., 1987, vol. 66, pp. 147s-154s.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, H.T., Jeng, S.L. & Kuo, T.Y. The microstructure and fracture behavior of the dissimilar alloy 690-SUS 304L joint with various Nb addition. Metall Mater Trans A 34, 1097–1105 (2003). https://doi.org/10.1007/s11661-003-0129-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-003-0129-6