Abstract

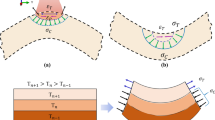

The thermal history developed in laser metal deposition (LMD) processes has been shown to be quite complex and results in the evolution of an equally complex microstructure. A companion article (Part I. Microstructural Characterization) discussed the LMD of Ti-6Al-4V, where the resultant microstructure consists of a periodic, scale-graded layer of basketweave Widmanstätten alpha and a banding that consists of colony Widmanstätten alpha. In order to understand the microstructural evolution in Ti-6Al-4V, a numerical thermal model based on the implicit finite-difference technique was developed to model LMD processes. The effect of different laser-scan velocities on the characteristics of the thermal history was investigated using an eight-layer single-line build. As the laser-scan speed decreases and the position within a layer increases, the peak temperature increases. The heating rate and the peak thermal gradient within a deposited layer were shown to follow the same trend as the peak temperature after two layers were deposited on top of the substrate. In general, the laser-scan speed or z-position within a layer did not have a significant effect on the cooling rate. The cooling rate in a newly deposited layer decreases as the number of layer additions increases. Given the predicted temperature vs time profile from the thermal model, the evolution of phase transformations occurring in the deposit is mapped as each layer is deposited. As a result of the thermal cycling imposed by the periodic deposition of material, a characteristic layer, consisting of two regions heated above and below the beta transus, forms in layer n due to the deposition of layer n+1.

Similar content being viewed by others

References

S.M. Kelly and S.L. Kampe: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1861–67.

M.L. Griffith, M.T. Ensz, J.D. Puskar, C.V. Robino, J.A. Brooks, J.A. Philliber, J.E. Smugeresky, and W.H. Hofmeister: in Solid Freeform and Additive Fabrication—2000, S.C. Danforth, D. Dimos, and F.B. Prinz, eds., Materials Research Society, Warrendale, PA, 2000, vol. 625, pp. 9–20.

M.L. Griffith, E. Schlienger, L.D. Harwell, M.S. Oliver, M.D. Baldwin, M.T. Ensz, M. Essien, J. Brooks, C.V. Robino, J.E. Smugeresky, W.H. Hofmeister, M.J. Wert, and D.V. Nelson: Mater. Design, 1999, vol. 20, pp. 107–13.

L. Costa, T. Reti, A.M. Deus, and R. Vilar: Proc. 2002 Int. Conf. on Metal Powder Deposition for Rapid Manufacturing, D.M. Keicher, J.W. Sears, and J.E. Smugeresky, eds., Metal Powder Industries Federation, Princeton, NJ, 2002, pp. 172–79.

W.H. Hofmeister, M.L. Griffith, M.T. Ensz, and J.E. Smugeresky: JOM, 2001, vol. 53 (9), pp. 30–34.

W.H. Hofmeister, M.J. Wert, J.E. Smugeresky, J.A. Philliber, M.L. Griffith, and M.T. Ensz: JOM, 1999, vol. 51 (7) (http://www.tms.org/pubs/journals/JOM/9907/Hofmeister/Hofmeister-9907.html).

A. Vasinota, J. Beuth, and M.L. Griffith: in Solid Freeform Fabrication Proc., D. Bourell, J. Beaman, R. Crawford, H. Marcus, and J. Barlow, eds., University of Texas, Austin, TX, 1999, pp. 383–91.

P.A. Kobryn and S.L. Semiatin: in Solid Freeform Fabrication Proc., D. Bourell, J. Beaman, R. Crawford, H. Marcus, and J. Barlow, eds., University of Texas, Austin, TX, 2000, pp. 58–65.

P.A. Kobryn and S.L. Semiatin: JOM, 2001, vol. 53 (9), pp. 40–42.

M.N. Özisik: Finite Difference Methods in Heat Transfer, CRC, Ann Arbor, MI, 1997.

S. Wolfram: Mathematica, 1998–2002.

S.M. Kelly: Master’s Thesis, Virginia Tech, Blacksburg, VA (http://scholar.lib.vt.edu/theses/available/etd-05222002-223436/), 2002.

K.C. Mills: Recommended Values of Thermophysical Properties for Selected Commercial Alloys, Woodhead, Cambridge, United Kingdom, 2002.

F.G. Arcella and F.H. Froes: JOM, 2000, vol. 52 (5), pp. 28–30.

T.J. Wieting and J.T. Schriempf: J. Appl. Phys., 1976, vol. 47, pp. 4009–11.

C. Hu and T.N. Baker: J. Mater. Processing Technol., 1999, vol. 94, pp. 116–22.

V.M. Majdic and G. Ziegler: Z. Metallk., 1973, vol. 64, pp. 751–58.

T. Ahmed and H.J. Rack: Mater. Sci. Eng. A, 1998, vol. 243, pp. 206–11.

T. DebRoy and S.A. David: Rev. Modern Phys., 1995, vol. 67, pp. 85–112.

K. Mundra, T. DebRoy, S.S. Babu, and S.A. David: Welding J., 1997, vol. 76, pp. 163s-171s.

B.A.B. Anderrson: J. Eng. Mater. Technol., 1978, vol. 100, pp. 356–62.

J. Goldak, A. Chakravarti, and M. Bibby: Metall. Trans. B, 1984, vol. 15B, pp. 299–305.

I. Katzarov, S. Malinov, and W. Sha: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1027–40.

F.J. Gil, J.M. Manero, and J.A. Planell: in Titanium ’95: Proc. 8th World Conf. on Titanium. H.M. Flower, ed., IOM, London, 1996, vol. 3, pp. 2454–61.

F.X. Gil Mur, D. Rodriguez, and J.A. Planell: J. Alloys Compounds, 1996, vol. 234, pp. 287–89.

J.C. Chesnutt, C.G. Rhodes, and J.C. Williams: in Titanium and Titanium Alloys, M.J. Donachie, ed., ASM, Materials Park, OH, 1982, pp. 100–39.

O.M. Ivasishin: Proc. 6th World Conf. on Titanium, G. Beranger, ed., Les Editions de Physique, Les Ulis Cedex, France, 1989, pp. 1535–39.

G. Lütjering, J. Albrecht, and O.M. Ivasishin: in Microstructure/Property Relationships of Titanium Alloys, J.A. Hall, ed., TMS, Warrendale, PA, 1994, pp. 65–75.

O.M. Ivasishin and G. Lütjering: Mater. Sci. Eng. A, 1993, vol. 168, pp. 23–28.

W. Szkliniarz and G. Smolka: J. Mater. Processing Technol., 1995, vol. 53, pp. 413–22.

P.S. Goodwin, C. Mitchell, J. Liang, J. Mei, and X. Wu: Proc. 2002 Int. Conf. on Metal Powder Deposition for Rapid Manufacturing, D.M. Keicher, J.W. Sears, and J.E. Smugeresky, eds., Metal Powder Industries Federation, Princeton, NJ, 2002, pp. 87–95.

P.A. Kobryn, E.H. Moore, and S.L. Semiatin: Scripta Mater., 2000, vol. 43, pp. 299–305.

S.M. Kelly: Oak Ridge National Laboratory, Oak Ridge, TN, unpublished research, 2004.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kelly, S.M., Kampe, S.L. Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part II. Thermal modeling. Metall Mater Trans A 35, 1869–1879 (2004). https://doi.org/10.1007/s11661-004-0095-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0095-7