Abstract

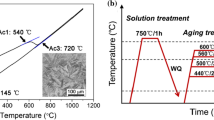

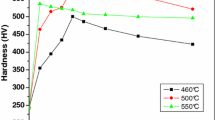

The precipitation kinetics in the aging temperature range of 713 to 813 K in a 2000 MPa grade Co-free maraging steel (Fe-18.9 pct Ni-4.1 pct Mo-1.9 pct Ti, mass pct) has been studied. Study on microstructure and mechanical properties showed that a great deal of Ni3Ti and a type of unknown spheroidal precipitates both with average diameter of 2 to 3 nm are formed in the early aging stage at 713 K, which results in a high strength and a relatively low fracture toughness. Ni3Ti precipitates grow into needle or rod shape and become the main precipitation as the aging time is prolonged. Strength increases and fracture toughness (K IC ) decreases with growth of the precipitates. The ultra-high strength of the maraging steel subjected to long-time aging at 713 K is attributed to the high resistance to coarsening of the precipitates. The strengthening in the underaged condition at 713 K is a combination of dislocations cutting through precipitates and the Orowan mechanisms. Aged at 813 K, the size of Ni3Ti precipitates is seriously nonuniform at the early stage and a small amount of interlath reverted austenite is formed. Thereafter, Ni3Ti precipitates coarsen sharply accompanied with the embrittlement. Intralath reverted austenite appears subsequently. In the later stage of aging, the coarsened Ni3Ti precipitates dissolve into the striplike intralath reverted austenite that is disorderly embedded in the matrix. All of these result in a low strength and low fracture toughness under overaging condition. Analysis shows that the formation of reverted austenite contains the diffusion and Kudjumov-Sachs (K-S) and Nishiyama-Wassermann (N-W) shear mechanisms.

Similar content being viewed by others

References

S. Floreen: Metall. Rev., 1968, vol. 126 (13), pp. 115–28.

V.K. Vasudervan, S.J. Kim, and C.M. Wayman: Metall. Trans. A, 1990, vol. 21A, pp. 2655–68.

U.K. Viswanathan, G.K. Dey, and M.K. Asundi: Metall. Trans. A, 1993, vol. 24A, pp. 2429–42.

W. Sha, A. Cerezo, and G.D.W. Smith: Metall. Trans. A, 1993, vol. 24A, pp. 1221–32.

Z.D. Yin, H. Suto, M. Nemoto, and J. Echigoya: J. Jpn. Inst. Met., 1983, vol. 47 (1), pp. 48–54 (in Japanese).

Xiaodong Li: Ph.D. Thesis, Harbin Institute of Technology, Harbin, 1993 (in Chinese).

W.A. Spitzing, J.M. Chilton, and C.J. Barton: ASM Trans. Q., 1968, vol. 61, pp. 635–39.

Q. Cai, J. Zhu, and C. He: Acta Physica Sinica, 1974, vol. 23 (3), p. 178 (in Chinese).

G.P. Miller and W.I. Mitchell: J. Iron Steel Inst., 1965, vol. 20, pp. 899–904.

G. Thomas, I.-L. Cheng, and J.R. Mihalisin: ASM Trans. Q., 1969, vol. 62, pp. 852–57.

R. Tewari, S. Mazumder, I.S. Batra, G.K. Dey, and S. Banerjee: Acta Mater., 2000, vol. 48, pp. 1187–200.

C. Servant and N. Bouzid: Acta Metall., 1988, vol. 36, pp. 2771–78.

W. Sha, A. Cerezo, and G.D.W. Smith: Metall. Trans. A, 1993, vol. 24A, pp. 1251–56.

P.P. Sinha, K.T. Tharian, K. Sreekumar, K.V. Nagarajan, and D.S. Sarma: Mater. Sci. Technol., 1998, vol. 14, pp. 1–9.

S. Floreen and R.F. Decker: ASM Trans. Q., 1962, vol. 55, pp. 518–30.

P.P. Sinha, D. Sivakumar, N.S. Babu, K.T. Tharian, and A. Natarajan: Steel Res., 1995, vol. 66 (11), pp. 490–94.

M. Farooque, H. Ayub, A. ul Haq, and A.Q. Khan: Mater. Trans. JIM, 1998, vol. 39, pp. 995–99.

Xiaodong Li and Zhongda Yin: Mater. Lett., 1995, vol. 24, pp. 239–42.

H.J. Rack and D. Kalish: Metall. Trans., 1971, vol. 2, pp. 3011–20.

J. Zhu, R. Li, and L. Zhang: Acta Metall. Sinica, 1986, vol. 22, pp. A304-A309 (in Chinese).

C.A. Pampillo and H.W. Paxton: Metall. Trans., 1972, vol. 3, pp. 2895–903.

D.M. Vanderwalker: Metall. Trans. A, 1987, vol. 18A, pp. 1191–94.

W. Sha, A. Cerezo, and G.D.W. Smith: Metall. Trans. A, 1993, vol. 24A, pp. 1233–39.

C.F. Hickey, Jr. and T.S. Thomas: in Maraging Steels: Recent Developments and Applications, R.K. Wilson, ed., TMS, Warrendale, PA, 1988, pp. 73–92.

R.K. Wilson, D.F. Smith, L.G. Coffee, J.S. Smith, and T.H. Bassford: in Maraging Steels: Recent Developments and Applications, R.K. Wilson, ed., TMS, Warrendale, PA, 1988, pp. 93–105.

Y. He, K. Liu, K. Yang: Acta Metall. Sinica, 2003, vol. 39, pp. 381–86 (in Chinese).

J.B. Leblond, J. Devaux, and J.C. Devaux: Int. J. Plasticity, 1989, vol. 5, pp. 551–72.

M. Coret, S. Calloch, and A. Combescure: Eur. J. Mech. A—Solid, 2004, vol. 23, pp. 823–42.

Y. He, K. Yang, W. Sha, and D.J. Cleland: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2747–55.

A. Arya, S. Banerjee, G.P. Das, I. Dasgupta, T. Saha-Dasgupta, and A. Mookerjee: Acta Mater., 2001, vol. 49, pp. 3575–87.

W. Song: Metallurgy, Metallurgical Engineering Industry Press, Beijing, 1992, p. 239 (in Chinese).

W. Sha, A. Cerezo, and G.D.W. Smith: Surf. Sci., 1991, vol. 246, pp. 278–84.

S.J. Kim and C.M. Wayman: Mater. Sci. Eng., 1990, vol. A128, pp. 217–30.

Seung-Ho Mun, Masashi Watanabe, Xingyi Li, Kyu Hwan Oh, David B. Williams, and Hu-Chul Lee: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1057–67.

T.J. Headley and J.A. Brooks: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 5–15.

A. Gemperle, J. Gemperlova, W. Sha, and G.D.W. Smith: Mater. Sci. Technol., 1992, vol. 8, pp. 546–54.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

He, Y., Yang, K. & Sha, W. Microstructure and mechanical properties of a 2000 MPa grade co-free maraging steel. Metall Mater Trans A 36, 2273–2287 (2005). https://doi.org/10.1007/s11661-005-0100-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0100-9