Abstract

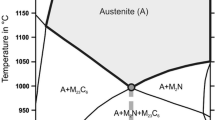

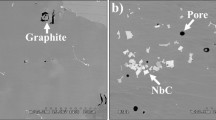

A powder metallurgical (PM) processing route for the manufacturing of two different refractory metal silicide alloys comprising inert gas atomization of presintered bars, hot isostatic pressing, and hot extrusion (reduction in cross section of 6:1) was established. The mechanical properties between room temperature and 1200 °C of the PM-processed Mo-3Si-1B and Nb-24Ti-20Si-5Cr-3Hf-2Al alloys (in wt pct) were assessed with tensile tests vs a state-of-the-art Ni-base single crystalline alloy (CMSX 4) and a directionally solidified (MASC) niobium-base silicide alloy, respectively. The microstructural characterization of both the hot-isostatically pressed and extruded materials was carried out applying scanning electron microscopy (SEM), energy-dispersive X-ray (EDX), and X-ray diffraction (XRD) analysis. The Mo-Si-B alloy is characterized by an intermetallic matrix surrounding globular Mo particles in the hot isostatic press and a nearly continuous molybdenum solid solution matrix with dispersed intermetallic particles in the hot-extruded condition. Hot extrusion results in a substantial reduction of the DBTT of about 200 °C and tensile strengths superior to CMSX 4 at temperatures above 1000 °C. In the case of the Nb-base silicide alloy, a niobium solid solution surrounding intermetallic particles with Nb5Si3-type structure characterizes the final alloy. In the intermediate temperature range of 500 °C to 816 °C, a strength level equivalent to the directionally solidified MASC alloy was observed.

Similar content being viewed by others

References

W.S. Walston, K.S. O’Hara, E.W. Ross, T.S. Pollock, and W.H. Murphy: Proc. Conf. Superalloys 1996, R.D. Kissinger et al., eds., TMS, Warrendale, PA, 1996, pp. 27–34.

S. Bose and J. DeMasi-Marcin: Thermal Barrier Coating Workshop NASA Lewis Research Center, Cleveland, OH, 1995, NASA Conf. Publication 3312, pp. 63–77.

D.M. Dimiduk and J.H. Perepezko: MRS Bull., 2003, vol. 28, pp. 639–45.

R. Eck and J. Tinzl: Proc. Symp. AMAX Research Center, K.H. Riska, M. Semchysten, and E.P. Whelan, eds., AMAX Research Center, Ann Arbor, MI, 1985, pp. 21–28.

H. Nowotny, R. Kiefer, and F. Benesovsky: Plansee Berichte Pulvermetallurgie, 1957, vol. 5, pp. 86–93.

D.M. Berczik: U.S. Patent 5,595,616, 1997.

D.M. Berczik: U.S. Patent 5,693,616, 1997.

J.J. Kruzic, J.H. Schneibel, and R.O. Ritchie: Scripta Mater., 2004, vol. 50, pp. 459–64.

M.R. Jackson and B.P. Bewlay: U.S. Patent 5,833,773, Nov. 10, 1998.

M.R. Jackson and B.P. Bewlay: U.S. Patent 5,932,033, Aug. 3, 1999.

M.R. Jackson and B.P. Bewlay: U.S. Patent 5,942,055, Aug 24, 1999.

M.R. Jackson, B.P. Bewlay, and J.-C Zhao: U.S. Patent 6,419,765, Jul. 16, 2002.

M.R. Jackson, B.P. Bewlay, and J.-C Zhao: U.S. Patent 6,428,910, Aug. 6, 2002.

P.R. Subramian, M.G. Mendiratta, and D.M. Dimiduk: U.S. Patent 5,741,376, Apr. 21, 1998.

B.P. Bewlay, J.J. Lewandowski, and M.R. Jackson: JOM, 1997, Aug., pp. 44–45.

B.P. Bewlay, M.R. Jackson, and H.A. Lipsitt: Proc. 1997 Conf. on Processing and Design Issues in High Temperature Materials, N.S. Stoloff and R.H. Jones, eds., TMS, Warrendale, PA, 1997, pp. 247–62.

B.P. Bewlay, M.R. Jackson, and H.A. Lipsitt: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3801–08.

B.P. Bewlay, M.R. Jackson, J.-C. Zhao, P.R. Subramian, M.G. Mendiratta, and J.J. Lewandowski: MRS Bull., 2003, vol. 28, pp. 646–53.

M.G. Mendiratta, T.A. Parthasarathy, and D.M. Dimiduk: Intermetallics, 2002, vol. 10, pp. 225–32.

J.-C. Zhao, B.P. Bewlay, M.R. Jackson, and L.A. Peluso: Proc. 2001 Int. Symp. on Structural Intermetallics 2001, K.J. Hemker, D.M. Dimiduk, H. Clemens, R. Darolia, H. Inui, J.M. Larsen, V.K. Sikka, M. Thomas, and J.D. Whittenberger, eds., TMS, Warrendale, PA, 2001, pp. 483–91.

P. Jéhanno, M. Heilmaier, and H. Kestler: Intermetallics, 2004, vol. 12, pp. 1005–09.

G.J. Richardson, D.N. Hawkins, and C.M. Sellars: Worked Examples in Metalworking, The Institute of Metals, London, 1985.

C.A. Nunes, R. Sakidja, Z. Dong, and J.H. Perepezko: Intermetallics, 2000, vol. 8, p. 327–37.

R.M. German: Powder Metallurgy Science, Metal Powder Industry Federation, Princeton, NJ, 1984.

H.M. Rietveld: J. Appl. Cryst., 1969, vol. 2, pp. 65–71.

O. Kerle: In Plansee Catalogue, Refractory Metals and Alloys, 2002.

H.J. Frost and M.F. Ashby: Deformation Mechanism Maps, Pergamon Press, New York, NY, 1982.

L. Northcott: Molybdenum, Butterworths Scientific Publications, London, 1956.

F. Schubert, H.-J. Penkalla, and L. Singheiser: Z. Metallkd., 2003, no. 94, vol. 6, pp. 705–10.

G.A. Geach and J.R. Hughes: Plansee Seminar Proc. 1955, Pergamon Press Ltd., London, 1956, pp. 245–53.

R.I. Jaffee, C.T. Sims, and J.J. Harwood: Plansee Seminar Proc. 1958, Pergamon Press Ltd., London, 1959, pp. 380–411.

B.P. Bewlay, R.R. Bishop, and M.R. Jackson: Z. Metallkd., 1996, no. 90, vol. 6, pp. 413–22.

S. Woodard, R. Raban, J. Myers, and D. Berczik: EP 1382700A1. European Patent Application 2004.

Author information

Authors and Affiliations

Additional information

This article is based on a presentation made in the symposium entitled “Beyond Nickel-Base Superalloys,” which took place March 14–18, 2004, at the TMS Spring meeting in Charlotte, NC, under the auspices of the SMD-Corrosion and Environmental Effects Committee, the SMD-High Temperature Alloys Committee, the SMD-Mechanical Behavior of Materials Committee, and the SMD-Refractory Metals Committee.

Rights and permissions

About this article

Cite this article

Jéhanno, P., Kestler, H., Venskutonis, A. et al. Assessment of a powder metallurgical processing route for refractory metal silicide alloys. Metall Mater Trans A 36, 515–523 (2005). https://doi.org/10.1007/s11661-005-0165-5

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0165-5