Abstract

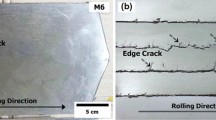

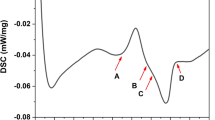

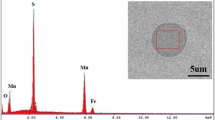

Anisotropy of forged steel components is especially adverse when it concerns rotationally symmetric components. Manganese sulfides (MnS) in steels may be desired for their improvement of machining properties; however, they also deteriorate fatigue behavior. A quantification of the effect of MnS on anisotropy is necessary to find an optimum for component dimensioning. To isolate the influence of MnS on anisotropy only, high cleanness of the test material is required. The test material in the current investigation was molten in a vacuum furnace to high-cleanness composition. Materials with two different S levels were produced to detect variations in anisotropy according to amount, shape, and distribution of the MnS inclusions. The two batches were cross-rolled to plates with a deformation ratio of 4.5. The MnS phase constitutes, upon forging or rolling, pancake-shaped inclusions. In the case of cross-rolling, an in-plane rotational symmetry of the inclusions could be created. The shape and size of these inclusions are essential for the mechanical behavior of the material. Push-pull fatigue testing was performed in longitudinal (in plane) and short transversal directions relative to the rolling plane. The results showed strong anisotropy of the fatigue behavior with inferior performance in short transverse directions where the principal stress is perpendicular to the flattened inclusions. The anisotropy was somewhat more pronounced for the high-S material, resulting from a different fatigue crack growth mechanism.

Similar content being viewed by others

References

C. Kaynak, A. Ankara, and T.J. Baker: Mater. Sci. Technol. (UK), 1996, vol. 12, pp. 557–62.

R. Kiessling: Nonmetallic Inclusions and Their Effects on the Properties of Ferrous Alloys, in Encyclopedia of Materials: Science and Technology, Bernhard Ilschner, ed., Elsevier Science Ltd., Oxford, UK, 2001, pp. 6278–83.

W.C. Leslie: ISS Trans., 1983, vol. 2, pp. 1–24.

I.C. Mayes and T.J. Baker: Mater. Sci. Technol., 1986, vol. 2, pp. 133–39.

E. Doege: Einfluss des Faserverlaufes auf die Schwingfestigkeit und die mechanischen Eigenschaften eines unlegierten Vergütungsstahls in Abhängigkeit vom Schwefelgehalt, Umformgrad und von der Umformtemperatur. IFUM Do 190/49, Hannover, Germany, 1987.

M. Wahlster, H. Heimbach, and K. Forch: Stahl und Eisen, 1969, vol. 89, pp. 1037–44.

Haglund, S.: Jernkontoret, Verein Deutscher Eisenhüttenleute, Düsseldorf, Germany, 2004, pp. 4:4–23.

T.J. Baker, K.B. Gove, and J.A. Charles: Met. Technol., 1976, vol. 3, pp. 183–93.

R. Kiessling and N. Lange: Non-metallic Inclusions in Steel (Parts—IV), 2nd ed., The Metals Society, London, 1978, pp. 114–27.

F. Matsuno, S.I. Nishikida, and H. Ikesaki: Trans. Iron Steel Inst. Jpn., 1985, vol. 25, pp. 989–98.

A. El-Ghazaly: Neue Hutte (Germany), 1992, vol. 37, pp. 399–404.

W.B. Morrison: Metals Technology, 1975, pp. 33–41.

A.D. Wilson: “Characterization of Inclusions in Plate Steels and Their Influence on Mechanical Properties. Inclusions and their Influence on Material Behavior,” ASM International, Chicago, 1989.

D. Brooksbank and K.W. Andrews: J. Iron Steel Inst., 1969, vol. 207, pp. 474–83.

D. Brooksbank and K.W. Andrews: J. Iron Steel Inst., 1972, vol. 210, pp. 246–55.

G. Härkegård: Eng. Fracture Mech., 1974, vol. 6, pp. 795–803.

ASTM-International: Designation: E 399 - 90, Metals Test Methods and Analytical Procedures, in Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA, 2001, pp. 434–37.

ASTM-International: Designation: E 1245 - 03, Standard Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis, in Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA, 2003, pp. 1–8.

G.F. Vander Voort: in Bearing Steels: into 21st Century, ASTM STP 1327, J. Joseph J.C. Hoo, and Willard B. Green, eds., ASTM, West Conshohocken, PA, 1998, pp. 13–26.

S.B. Hosseini: Bonding Between MnS Inclusions and the Steel Matrix, Chalmers Univ. Tech., Göteborg, Sweden, 2005.

W.J. Dixon and A.M. Mood: J. Am. Stat. Assoc., 1948, vol. 43, pp. 108–26.

Y. Murakami: Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions. Elsevier, Amsterdam, 2002, p. 369.

DIN-50602-1985, Beuth Verlag GmbH, ed., Berlin, Germany, 1985, pp. 1–9.

F. Sandberg: Examination of tooth fractures on countershafts (2nd gear) due to fatigue initiated from micro- and macro inclusions, with or without overheating of dedendum flanks, P/N 1521411 & 1521930. ER-505825 (Volvo Internal Report). Volvo Powertrain, Göteborg, Sweden, 2003.

M. Nordqvist: Steel Cleanliness: Evaluation of Immersion Ultrasonic Testing and Examination of Detected Inclusions. 2003.

S. Suresh: Fatigue of Materials, 2nd ed., Cambridge University Press, 2004, p. 679.

ASM-International: ASM Handbook, 1st ed., ASM International, 1996.

N.E. Dowling: Mechanical Behavior of Materials, 2nd ed., Prentice Hall, Upper Saddle River, NJ, 1999.

A.D. Wilson: Fractographic Characterization of the Effect of Inclusions on Fatigue Crack Propagation. Fractography and Materials Science, Williamsburg, VA, 1981, pp. 166–86.

J. Höijer: Anisotropic Fatigue Properties of Engineering Steel: A Microstructural Characterisation. Chalmers Reproservice, Göteborg, Sweden, 2003.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Temmel, C., Ingesten, NG. & Karlsson, B. Fatigue anisotropy in cross-rolled, hardened medium carbon steel resulting from MnS inclusions. Metall Mater Trans A 37, 2995–3007 (2006). https://doi.org/10.1007/s11661-006-0181-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-0181-0