Abstract

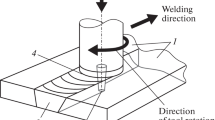

Three-dimensional visco-plastic flow of metals and the temperature fields in friction stir welding have been modeled based on the previous work on thermomechanical processing of metals. The equations of conservation of mass, momentum, and energy were solved in three dimensions using spatially variable thermophysical properties and non-Newtonian viscosity. The framework for the numerical solution of fluid flow and heat transfer was adapted from decades of previous work in fusion welding. Non-Newtonian viscosity for the metal flow was calculated considering strain rate, temperature, and temperature-dependent material properties. The computed profiles of strain rate and viscosity were examined in light of the existing literature on thermomechanical processing. The heat and mass flow during welding was found to be strongly three-dimensional. Significant asymmetry of heat and mass flow, which increased with welding speed and rotational speed, was observed. Convective transport of heat was an important mechanism of heat transfer near the tool surface. The numerically simulated temperature fields, cooling rates, and the geometry of the thermomechanically affected zone agreed well with independently determined experimental values.

Similar content being viewed by others

References

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Templesmith, and C.J. Dawes: International patent application no. PCT/GB92/02203 and GB patent application no. 9125978.9, 1991.

M.J. Russel and H.R. Shercliff: Proceedings of the 7th International Conference on “Joints in Aluminum” (INALCO ’98), The Welding Institute, Cambridge, U.K., 1998. vol. 2, pp. 185–95.

J.E. Gould and Z. Feng: J. Mater. Process. Manuf. Sci., 1998, vol. 7, pp. 185–94.

H. Schmidt, J. Hattel, and J. Wert: Modeling Simulations Mater. Sci. Eng., 2004, vol. 12, pp. 143–57.

Ø. Frigaard, Ø. Grong, and O.T. Midling: Metall. Mater. Trans. A, 2001, vol. 32, pp. 1189–200.

Y.J. Chao, X. Qi, and W. Tang: Trans. ASME, 2003, vol. 125, pp. 138–45.

M. Song and R. Kovacevic: Proc. Instn. Mech. Engrs. Part B: J. Eng Manuf., 2003, vol. 217 (B1), pp. 73–85.

M. Song and R. Kovacevic: Int. J. Machine Tool Manuf., 2003, vol. 43 (6), pp. 605–15.

M. Song and R. Kovacecic: Proc. Instn. Mech. Engrs. Part B: J. Eng Manuf., 2004, vol. 218, pp. 17–33.

M.Z.H. Khandkar, J.A. Khan, and A.P. Reynolds: Sci. Technol. Weld. Joining, 2003, vol. 8 (3), pp. 165–74.

P.A. Colegrove and H.R. Shercliff: Sci. Technol. Weld. Joining, 2004, vol. 9 (4), pp. 345–51.

T.U. Seidel and A.P. Reynolds: Sci. Technol. Weld. Joining, 2003, vol. 8, pp. 175–83.

C.B. Smith, G.B. Bendzsak, T.H. North, J.F. Hinrichs, J.S. Noruk, and R.J. Heideman: Proceedings of the 9th International Conference on Computer Technology in Welding, Detroit, 2000, pp. 475–86.

P. Ulysse: Int. J. Machine Tools Manuf., 2002, vol. 42, pp. 1549–57.

P.A. Colegrove and H.R. Shercliff: J. Mater. Process. Technol., 2005, in press.

W. Zhang, G.G. Roy, J.W. Elmer, and T. DebRoy: J. Appl. Phys., 2003, vol. 93, pp. 3022–33.

T. Sheppard and D.S. Wright: Metal. Technol, 1979, vol. 6, pp. 215–23.

O.C. Zienkiewicz and I.C. Cormeau: Int. J. Numer. Methods Eng., 1974, vol. 8, pp. 821–45.

T. Sheppard and A. Jackson: Mater. Sci. Technol., 1997, vol. 13, pp. 203–09.

ASM Handbook, vol. 2, ASM International, Columbus, OH, 1990, pp. 102–03.

D.R. Lesuer, G.J. Kay, and M.M. LeBlanc: “Modeling Large-Strain, High-Rate Deformation in Metals,” Third Biennial Tri-Laboratory Engineering Conference on Modeling and Simulation, Pleasanton. CA, November 3–5, 1999. Also available on the web at http://www.llnl.gov/tid/lof/documents/pdf/243782.pdf as a report of the Lawrence Livermore National Laboratory Report #UCRL-JC-134118 dated July 20, 2001.

S.V. Patankar: Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corporation, New York, NY, 1980.

X. He, J. Elmer, and T. DebRoy: J. Appl. Phys., 2005, vol. 97, p. 84909.

A. De and T. DebRoy: Welding J., 2005, vol. 84 (7), pp. 101–12.

S. Mishra and T. DebRoy: J. Phys. D. 2005, vol. 38, pp. 2977–85.

W. Zhang, T. DebRoy, and J.W. Elmer: Sci. Technol. Weld. Joining, 2005, vol. 10 (5), pp. 574–82.

W. Zhang, T. DebRoy, T.A. Palmer, and J.W. Elmer: Acta Mater., 2005, vol. 53 (16), pp. 4441–53.

S. Mishra and T. DebRoy: J. Appl. Phys., 2005, vol. 98, p. 044902.

P.J. Halley and M.E. Mackay: J. Rheol., 1994, vol. 38 (1), pp. 41–51.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nandan, R., Roy, G.G. & Debroy, T. Numerical simulation of three-dimensional heat transfer and plastic flow during friction stir welding. Metall Mater Trans A 37, 1247–1259 (2006). https://doi.org/10.1007/s11661-006-1076-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-1076-9