Abstract

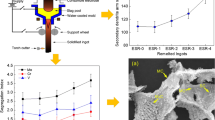

On the basis of a numerical model, the temperature and liquid fraction of spray-formed H13 tool steel are calculated as a function of time. Results show that a preheated substrate at the appropriate temperature can lead to very low porosity by increasing the liquid fraction in the deposited steel. The calculated cooling rate can lead to a microstructure consisting of martensite, lower bainite, retained austenite, and proeutectoid carbides in as-spray-formed material. In the temperature range between the solidus and liquidus temperatures, the calculated temperature of the spray-formed material increases with increasing substrate preheat temperature, resulting in a very low porosity by increasing the liquid fraction of the deposited steel. In the temperature region where austenite decomposition occurs, the substrate preheat temperature has a negligible influence on the cooling rate of the spray-formed material. On the basis of the calculated results, it is possible to generate sufficient liquid fraction during spray forming by using a high growth rate of the deposit without preheating the substrate, and the growth rate of the deposit has almost no influence on the cooling rate in the temperature region of austenite decomposition.

Similar content being viewed by others

References

K.M. McHugh, J.E. Folkestad: Proc. SDMA 2003 and ICSF V, Bremen, Germany, 2003, pp. 5–123

K.M. McHugh: in Solidification 1998, S.P. Marsh, J.A. Dantzig, R. Trivedi, W. Hofmeister, M.G. Chu, E.J. Lavernia, and J.H. Chun, eds., TMS, Warrendale, PA, 1998, p. 427

Source Book on Industrial Alloy and Engineering Data, ASM, Materials Park, OH, 1987, pp. 255–67

E.S. Lee, W.J. Park, K.H. Baik, S. Ahn: Scripta Mater., 1998, vol. 39, pp. 1133–38

E.J. Lavernia, Y. Wu: Spray Atomization and Deposition, John Wiley & Sons, Inc., New York, NY, 1996, pp. 343–70

Q. Xu, E.J. Lavernia: Acta Mater., 2001, vol. 49, pp. 3849–61.

K. Lubanska: JOM, 1970, vol. 22(2), pp. 45–49

P.S. Grant, B. Cantor, L. Katgerman: Acta Metall. Mater., 1993, vol. 41, pp. 3109–18

Q. Xu, V.V. Gupta, E.J. Lavernia: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 527–39

Q. Xu, V.V. Gupta, E.J. Lavernia: Acta Mater., 2000, vol. 48, pp. 835–49

S. Annavarapu, D. Apelian, A. Lawley: Metall. Trans. A, 1990, vol. 21A, pp. 3237–56

B.C. Moon, Z.H. Lee, D.R. White, E.J. Lavernia: J. Mater. Res., 2000, vol. 15, pp. 1669–78

Crucible Tool Co., private communication, Syracuse, NY, 2004

S. Annavarapu, R. Doherty: Int. J. Powder Metall., 1993, vol. 29, pp. 331–43

Y.J. Lin, K.M. McHugh, Y.Z. Zhou, E.J. Lavernia: Scripta Mater., 2006, vol. 55, pp. 581–84

G.A. Roberts and R.A. Cary: Tool Steels, ASM, Materials Park, OH, 1980, pp. 187 and 579–89

Acknowledgments

The authors gratefully acknowledge the financial support from the United States Army Research Office (Grant No. W911NF-06-1-0230).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 28, 2006.

Rights and permissions

About this article

Cite this article

Lin, Y., McHugh, K., Zhou, Y. et al. Modeling the Spray Forming of H13 Steel Tooling. Metall Mater Trans A 38, 1632–1637 (2007). https://doi.org/10.1007/s11661-007-9159-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9159-9