Abstract

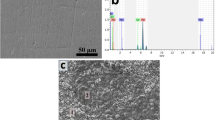

Pyrochemical reprocessing in molten chloride salt medium has been considered as one of the best options for the reprocessing of spent metallic fuels of future fast breeder reactors. The unit operations such as salt preparation, electrorefining, and cathode processing involve the presence of molten LiCl-KCl eutectic salt from 673 to 1373 K (400 to 1100 °C). The present work discusses the corrosion behavior of electroformed nickel (EF Ni) without and with nickel-tungsten (Ni-W) coating, 316L SS, and INCONEL 625 alloy in molten LiCl-KCl eutectic salt at 673 K, 773 K, and 873 K (400 °C, 500 °C, and 600 °C) in the presence of air. The weight percent loss of the exposed samples was determined by the weight loss method and surface morphology of the salt exposed, and product layers were examined by scanning electron microscopy (SEM). X-ray diffraction (XRD) and energy-dispersive X-ray (EDX) analysis were also carried out on the exposed and corrosion product layers to understand the phases present and the corrosion mechanism involved. The results of the present study indicated that INCONEL 625 alloy showed superior corrosion resistance compared to electroformed nickel (EF Ni), EF Ni with nickel-tungsten (Ni-W) coating (EF Ni-W), and 316L SS. The EF Ni with Ni-W coating exhibits better corrosion resistance than EF Ni without tungsten coating. Based on the surface morphology, XRD, and EDX analysis of corrosion product layers, the mechanism of corrosion of INCONEL 625 and 316L involves formation of chromium-rich compound at the surface and subsequent spallation. For the EF Ni, the porous thick NiO corrosion product allows the penetration of salt, thus accelerating the corrosion. Improved corrosion resistance of EF Ni-W was attributed to the W-rich NiO layer, while for INCONEL 625, the adherent and protective NiO layer improved the corrosion resistance. The article highlights the results of the present investigation.

Similar content being viewed by others

Notes

INCONEL is a trademark of Special Metals Corporation, New Hartford, NY.

HASTELLOY-X is a trademark of Haynes International Inc., Kokomo, IN.

References

C.A.C. Sequeria: Molten Salt Forum, 2003, vol. 7, pp. 3–40.

B. Raj, H.S. Kamath, R. Natarajan, and P.R. Vasudeva Rao: Prog. Nucl. Energy, 2005, vol. 47, pp. 369–79.

J.M. Malo, J. Uruchurtu, and C. Martinez: Molten Salt Forum, 2003, vol. 7, pp. 311–24.

T. Tzvetkoff, A. Girginov, and M. Bojinov: J. Mater. Sci., 1995, vol. 30, pp. 5561–75.

S.H. Cho, J.S. Zhang, Y.J. Shin, S.W. Park, and H.S. Park: J. Nucl. Mater., 2004, vol. 325, pp. 13–17.

Tzvety Tzvetkoff and Petia Gencheva: Mater. Chem. Phys., 2003, vol. 82, pp. 897–904.

D. Zhu and B. Wei: Proc. 1st Int. Symp. on Electrochemical Microfabrication, 1992, vol. 92, pp. 333–39.

T. Hart and A. Watson: Met. Finish., 2001, vol. 99, pp. 387–98.

M. Tada and Y. Ito: Mater. Sci. Forum., 1995, vols. 185–188, pp. 917–24.

W.A. Friend: Corrosion of Nickel and Nickel Base Alloys, John Wiley-Interscience Publication, New York, NY, 1980.

T. Tzvetkoff, A. Girginov, and M. Bojinov: J. Mater. Sci., 1995, vol. 30, pp. 5561–75.

R.M. Arons and C.M. Edstrom: Thin Solid Films, 1980, vol. 73, pp. 53–58.

N. Eliaz, T.M. Sridhar, and E. Gileadi: Electrochim. Acta, 2005, vol. 50, pp. 2893–2904.

Y.S. Li, M. Spiegel, and S. Shimada: Mater. Chem. Phys., 2005, vol. 93, pp. 217–23.

Y. Hosoya, Takayuki, T. Yoneoka, and S. Tanaka: J. Nucl. Mater., 1997, vol. 248, pp. 348–53.

Powder Diffraction File-2 (PDF-2) JCPDS-ICDD, PCPDFWIN Version 2.02, May 1999.

F. Colom and A. Bodalo: Corr. Sci., 1972, vol. 12, pp. 731–38.

K. Sriraman, S. Ganesh Sundara Raman, and S.K. Seshadri: Mater. Sci. Eng. A, 2007, vols. 460–461, pp. 39–45.

A. Ravi Shankar and U. Kamachi Mudali: Mater. Corr., 2008, vol. 59, pp. 878–82.

C.F. Windisch, Jr., C.H. Henager, Jr., M.H. Engelhard, and W.D. Bennett: J. Nucl. Mater., 2009, vol. 383, pp. 237–43.

S.-H. Cho, J.-M. Hur, C.-S. Seo, and S.-W. Park: J. Alloy Compd., 2008, vol. 452, pp. 11–15.

S.-H. Cho, J.-M. Hur, C.-S. Seo, J.-S. Yoon, and S.-W. Park: J. Alloy Compd., 2009, vol. 468, pp. 263–69.

J. Birnie, C. Craggs, D.J. Gardiner, and P.R. Graves: Corr. Sci., 1992, vol. 33, pp. 1–12.

Acknowledgments

Thanks are due to CECRI, Karaikudi, for providing EF Ni and EF Ni-W samples; Smt Kalavathy for GIXRD; Smt M. Radhika for SEM examination; and S. Remya for LRS.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 15, 2009.

Rights and permissions

About this article

Cite this article

Ravi Shankar, A., Mathiya, S., Thyagarajan, K. et al. Corrosion and Microstructure Correlation in Molten LiCl-KCl Medium. Metall Mater Trans A 41, 1815–1825 (2010). https://doi.org/10.1007/s11661-010-0223-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-010-0223-5