Abstract

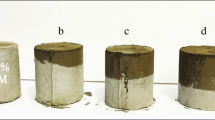

This paper reports on an attempt to independently evaluate the validity and applicability of a new compaction equation recently presented by Gerdemann and Jablonski [Metallurgical and Materials Transactions A, 42 (2011) 1325–1333] using experimental data. Furthermore, the rationality of Gerdemann and Jablonski’s interpretation of the equation parameters is examined. The results are discussed in terms of the comparative evaluation of four different titanium powders (sponge Ti, CP TiH2, Grade 2 CP Ti, and TiH2-SS316L nanocomposite blend prepared by high energy milling) cold pressed in die to compaction pressures of up to 1300 MPa.

Similar content being viewed by others

References

P. Paronen and J. Llkka: in Pharmaceutical Powder Compaction Technology, G. Alderborn and C. Nystrom, eds. CRC Press, Florida, 1995, pp. 55–75.

G. Bockstiegel, “Modern developments in powder metallurgy,” Proc. Int. Powder Met. Conf., vol. 1, pp. 155–187, 1966.

P. Y. Huang, Powder Metallurgy Principle. Beijing: Metallurgical Industry Press, 1982, pp. 373–374.

S. J. Gerdemann and P. D. Jablonski, “Compaction of Titanium Powders,” Metall. Mater. Trans. A, vol. 42A, pp. 1325–1333, Nov. 2011.

F. H. Froes, S. J. Mashl, J. C. Hebeisen, V. S. Moxson, and V. A. Duz, “The technologies of titanium powder metallurgy,” JOM, vol. 56, no. 11, pp. 46–48, Nov. 2004.

J. M. Sonnergaard, “Investigation of a new mathematical model for compression of pharmaceutical powders,” Eur. J. Pharm. Sci., vol. 14, no. 2, pp. 149–157, 2001.

P. Adapa, L. Tabil, and G. Schoenau, “Compaction characteristics of barley, canola, oat and wheat straw,” Biosyst. Eng., vol. 104, no. 3, pp. 335–344, Nov. 2009.

S. Mallick, “Rearrangement of particle and compactibility, tabletability and compressibility of pharmaceutical powder : A rational approach,” J. Sci. Indusctrial Res., vol. 73, no. January, pp. 51–56, 2014.

K. Katsuyoshi and W. Ryuzo, “Analysis of Warm Compaction Behavior of Iron Powder Particles via Cooper-Eaton Equation,” Trans. JWRI, vol. 35, no. 2, pp. 47–51, 2006.

A. R. Cooper and L. E. Eaton, “Compaction behavior of several ceramic powders,” J. Am. Ceram. Soc., vol. 45, no. 3, pp. 97–101, 1962.

D. Jeyasimman, K. Sivaprasad, S. Sivasankaran, and R. Narayanasamy, “Fabrication and consolidation behavior of Al 6061 nanocomposite powders reinforced by multi-walled carbon nanotubes,” Powder Technol., vol. 258, no. 0, pp. 189–197, May 2014.

P. J. Denny, “Compaction equations: a comparison of the Heckel and Kawakita equations,” Powder Technol., vol. 127, no. 2, pp. 162–172, Oct. 2002.

M. Qian, “Cold compaction and sintering of titanium and its alloys for near-net-shape or preform fabrication,” Int. J. Powder Metall., vol. 46, no. 5, pp. 29–44, 2010.

R. Frykholm and H. Vidarsson: “Ti Alloys in PM Applications”, in World Congress PM2014 in Orlando, 2014.

W. Chen, Y. Yamamoto, W. H. Peter, M. B. Clark, S. D. Nunn, J. O. Kiggans, T. R. Muth, C. A. Blue, J. C. Williams, and K. Akhtar, “The investigation of die-pressing and sintering behavior of ITP CP-Ti and Ti-6Al-4V powders,” J. Alloys Compd., vol. 541, pp. 440–447, Nov. 2012.

A. Jimoh, I. Sigalas, and M. Hermann, “Densification of titanium (Ti) from titanium hydride (TiH2) powder through dehydrogenation and pressureless sintering Process,” J. Sci. Technol. Math. Educ., vol. 7, no. 2, pp. 42–52, 2011.

P. G. Esteban, Y. Thomas, E. Baril, E. M. Ruiz-Navas, and E. Gordo, “Study of compaction and ejection of hydrided-dehydrided titanium powder,” Met. Mater. Int., vol. 17, no. 1, pp. 45–55, Feb. 2011.

S.-T. Hong, Y. Hovanski, C. A. Lavender, and K. S. Weil, “Investigation of Die Stress Profiles During Powder Compaction Using Instrumented Die,” J. Mater. Eng. Perform., vol. 17, no. 3, pp. 382–386, Apr. 2008.

S. Chikosha, T. C. Shabalala, and H. K. Chikwanda, “Effect of particle morphology and size on roll compaction of Ti-based powders,” Powder Technol., vol. 264, pp. 310–319, Sep. 2014.

E. M. Borisovskaya, V. A. Nazarenko, Y. N. Podrezov, O. S. Koryak, Y. I. Evich, and V. F. Gorban, “Mechanical properties of powder titanium at different production stages. I. Densification curves for titanium powder billets,” Powder Metall. Met. Ceram., vol. 47, no. 7–8, pp. 406–413, 2008.

J. B. Lim, C. J. Bettles, B. C. Muddle, and N. K. Park, “Effects of Impurity Elements on Green Strength of Powder Compacts,” Mater. Sci. Forum, vol. 654–656, pp. 811–814, Jun. 2010.

K.K. Sobiyi: Machining Of Powder Metal Titanium, University of Stellenbosch, 2011.

J. Lou and B. Gabbitas: in International Titanium Powder Processing, Consolidation and Metallurgy Conference, 2013.

ASTM D7481—09 Standard Test Methods for Determining Loose and Tapped Bulk Densities of Powders using a Graduated Cylinder, Book of Standards Volume: 04.09. ASTM International, West Conshohocken, PA, 2009.

Test Methods Used During Development or Manufacture: Bulk Density and Tapped Density of Powders, Supplementary Information in The International Pharmacopoeia, 4th Edition. WHO, Geneva, Switzerland, 2014.

O. V Tsodikov and M. T. Record, “General method of analysis of kinetic equations for multistep reversible mechanisms in the single-exponential regime: application to kinetics of open complex formation between Esigma70 RNA polymerase and lambdaP(R) promoter DNA.,” Biophys. J., vol. 76, no. 3, pp. 1320–29, Mar. 1999.

H. Motulsky and A. Christopoulos: Fitting Models to Biological Data Using Linear and Nonlinear Regression: A Practical Guide to Curve Fitting, Oxford University Press, 2004, pp. 317–19.

Z.-G. Mei, S.-L. Shang, Y. Wang, and Z.-K. Liu, “Density-functional study of the thermodynamic properties and the pressure–temperature phase diagram of Ti,” Phys. Rev. B, vol. 80, no. 10, p. 104116, Sep. 2009.

N. Velisavljevic, S. MacLeod, and H. Cynn: in Titanium Alloys—Towards Achieving Enhanced Properties for Diversified Applications, A.K.M.N. Amin, ed. InTech, 2012, pp. 67–86.

D. Errandonea, Y. Meng, M. Somayazulu, and D. Häusermann, “Pressure-induced alpha to omega transition in titanium metal: a systematic study of the effects of uniaxial stress,” Phys. B Condens. Matter, vol. 355, no. 1–4, pp. 116–125, Jan. 2005.

D. Trinkle, R. Hennig, S. Srinivasan, D. Hatch, M. Jones, H. Stokes, R. Albers, and J. Wilkins, “A New Mechanism for the Alpha to Omega Martensitic Transformation in Pure Titanium,” Phys. Rev. Lett., vol. 91, no. 2, p. 025701, Jul. 2003.

J. Zhang, Y. Zhao, R. S. Hixson, G. T. Gray, L. Wang, W. Utsumi, S. Hiroyuki, and H. Takanori, “Experimental constraints on the phase diagram of titanium metal,” J. Phys. Chem. Solids, vol. 69, no. 10, pp. 2559–2563, Oct. 2008.

V. Dmitriev, L. Dubrovinsky, T. Bihan, A. Kuznetsov, H.-P. Weber, and E. Poniatovsky, “Collapsed hexagonal ω phase in a compressed TiZr alloy: Angle-dispersive synchrotron-radiation X-ray diffraction study,” Phys. Rev. B, vol. 73, no. 9, p. 094114, Mar. 2006.

N. Endo, H. Saitoh, A. Machida, Y. Katayama, and K. Aoki, “Phase diagram and equation of state of TiH2 at high pressures and high temperatures,” J. Alloys Compd., vol. 546, pp. 270–274, Jan. 2013.

I. O. Bashkin, V. K. Fedotov, H.-J. Hesse, A. Schiwek, W. B. Holzapfel, and E. G. Ponyatovsky, “An in situ structural study of the high-pressure transformations in TiH0.74,” J. Phys. Condens. Matter, vol. 14, no. 5, pp. 955–966, Feb. 2002.

P. E. Kalita, A. L. Cornelius, K. E. Lipinska-Kalita, C. L. Gobin, and H. Peter Liermann: J. Phys. Chem. Solids, vol. 69, no. 9, pp. 2240–2244, 2008.

S. G. MacLeod, B. E. Tegner, H. Cynn, W. J. Evans, J. E. Proctor, M. I. McMahon, and G. J. Ackland, “Experimental and theoretical study of Ti-6Al-4V to 220 GPa,” Phys. Rev. B, vol. 85, no. 22, p. 224202, Jun. 2012.

E. Huang, W. A. Bassett, and P. Tao: in High-Pressure Research in Mineral Physics: A Volume in Honor of Syun-iti Akimoto, vol. 39, M.H. Manghnani and Y. Syono, eds. Washington, D. C.: American Geophysical Union, 1987, pp. 165–72.

R. G. Hennig, D. R. Trinkle, J. Bouchet, S. G. Srinivasan, R. C. Albers, and J. W. Wilkins, “Impurities block the alpha to omega martensitic transformation in titanium,” Nat. Mater., vol. 4, no. 2, pp. 129–133, Feb. 2005.

Acknowledgments

We are grateful to Thembinkosi Shabalala—for his contribution during the preparation of the mechanically blended powder—and to Jeff Benson—for his comments on the early versions of this paper. The contributions of Chris Machio and Silethelwe Chikosha especially are gratefully recognized. This research has been financially supported by the Department of Science and Technology through the Titanium Centre of Competence research program and the Council for Scientific and Industrial Research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 2, 2014.

Rights and permissions

About this article

Cite this article

Machaka, R., Chikwanda, H.K. An Experimental Evaluation of the Gerdemann–Jablonski Compaction Equation. Metall Mater Trans A 46, 2194–2200 (2015). https://doi.org/10.1007/s11661-015-2793-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2793-8