Abstract

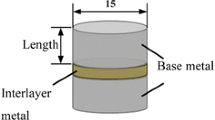

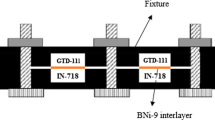

The microstructure and mechanical properties of transient liquid phase (TLP) bonded joints between dissimilar precipitation hardened IN939 and solid solution hardened IN625 with a Ni-Cr-Si-Fe-B filler alloy were studied. The TLP bonding was conducted in different bonding times (i.e., 15, 25, 35, 45, 60, and 90 minutes). Different phases, formed in the isothermally solidified zone (ISZ), on-cooling solidified zone, and diffusion affected zone (DAZ), were characterized using EDS, XRD, and EPMA analyses. A Ni-rich γ solid solution, CrB, and Ni3B were detected in the centerline of samples with incomplete isothermal solidification (i.e., 15 and 25 minutes), formed by binary and ternary eutectic reactions. Raising the time of bonding boosted isothermal solidification, resulting in a joint without deleterious eutectic microconstituents in bonding times of 35 minutes and higher. Chromium-rich borides were discovered in the DAZ of IN939, while the IN625-DAZ side was composed of chromium-molybdenum-rich borides. The concentration of alloying elements in the ISZ experienced an increment by further raising the bonding time to 90 minutes, creating a more homogenous bond with increased ISZ microhardness and mechanical properties. The highest shear strength (~ 92 and ~ 77 Pct that of the IN939 and IN625, respectively) and failure energy were attained for the 90-minutes sample. The fracture mechanism was also switched from a brittle semi-cleave morphology to a more ductile dimple-like morphology by increasing the bonding time from 15- to 90-minutes.

Similar content being viewed by others

References

A.P. Mouritz, Introduction to aerospace materials, Elsevier, Amsterdam, 2012.

M. Abedini, M.R. Jahangiri, P. Karimi, Oxid. Met., 2018, vol. 90, pp. 469-484.

M. Leary, M. Mazur, H. Williams, E. Yang, A. Alghamdi, B. Lozanovski, X. Zhang, D. Shidid, L. Farahbod-Sternahl, G. Witt, I. Kelbassa, P. Choong, M. Qian, M. Brandt, Mater. Des., 2018, vol. 157, pp. 179-199.

M. Jahangiri, S. Boutorabi, H. Arabi, Mater. Sci. Technol., 2012, vol. 28, pp. 1402-1413.

V. Shankar, K.B.S. Rao, S.L. Mannan, J. Nucl. Mater., 2001, vol. 288, pp. 222-232.

M. Khakian, S. Nategh, S. Mirdamadi, J. Alloy. Compd., 2015, vol. 653, pp. 386-394.

B. Binesh, A. Jazayeri-Gharehbagh, J. Mater. Sci. Technol., 2016, vol. 32, pp. 1137-1151.

N. Wikstrom, A. Egbewande, O. Ojo, J. Alloy. Compd., 2008, vol. 460, pp. 379-385.

F. Jalilian, M. Jahazi, R. Drew, Mater. Sci. Eng. A, 2006, vol. 423, pp. 269-281.

A. Malekan, M. Farvizi, S.E. Mirsalehi, N. Saito, K. Nakashima, Mater. Sci. Eng. A, 2019, vol. 755, pp. 37-49.

D.S. Duvall, W.A. Owczarski, D.F. Paulonis, Weld. J., 1974, vol. 53, pp. 203-214.

V. Maleki, H. Omidvar, M.-r. Rahimipour, T. Nonfer. Metal. Soc., 2016, vol.26, pp. 437-447.

N. Sheng, J. Liu, T. Jin, X. Sun, Z. Hu, J. Mater. Sci. Technol., 2015, vol. 31, pp. 129-134.

H.M. Hdz-García, A.I. Martinez, R. Muñoz-Arroyo, J.L. Acevedo-Dávila, F. García-Vázquez, F.A. Reyes-Valdes, J. Mater. Sci. Technol., 2014, vol. 30, pp. 259-262.

A. Kazazi, A. Ekrami, J. Manuf. Process., 2019, vol. 42, pp. 131-138.

N. Sheng, B. Li, J. Liu, T. Jin, X. Sun, Z. Hu, J. Mater. Sci. Technol., 2014, vol. 30, pp. 213-216.

A. Malekan, M. Farvizi, S.E. Mirsalehi, N. Saito, K. Nakashima, Mater. Sci. Eng. A, 2020, vol. 772, 138694.

F. Arhami, S.E. Mirsalehi, A. Sadeghian, M.H. Johar, J. Manuf. Process., 2019, vol. 37, pp. 203-211.

A.Y. Shamsabadi, R. Bakhtiari, J. Alloy. Compd., 2016, vol. 685, pp. 896-904.

B. Abbasi-Khazaei, A. Jahanbakhsh, R. Bakhtiari, Mater. Sci. Eng. A, 2016, vol. 651, pp. 93-101.

S. Hadibeyk, B. Beidokhti, S.A. Sajjadi, J. Mater. Process. Tech., 2018, vol. 255, pp. 673-678.

M. Salmaliyan, M. Shamanian, Heat. Mass. Transfer., 2019, pp. 1–11.

L.X. Zhang, Q. Chang, Z. Sun, Q. Xue, J.C. Feng, J. Manuf. Process., 2019, vol. 38, pp. 167-173.

D. Kokabi, A. Kaflou, R. Gholamipour, M. Pouranvari, J. Alloy. Compd., 2020, vol. 825, 153999.

S. Ghaderi, F. Karimzadeh, A. Ashrafi, S.H. Hosseini, J. Manuf. Process., 2020, vol. 60, pp. 213-226.

E.D. Moreau, S.F. Corbin, Metall. Mater. Trans. A., 2020, pp. 1–11.

A. Sadeghian, F. Arhami, S.E. Mirsalehi, J. Manuf. Process., 2019, vol. 44, pp. 72-80.

É.M. Miná, Y.C. da Silva, M.F. Motta, H.C. de Miranda, J. Dille, C.C. Silva, Mater. Charact., 2017, vol. 133, pp. 10-16.

O.A. Ojo, O. Aina, Metall. Mater. Trans. A., 2018, vol. 49, pp. 1481-1485.

M. Jahangiri, H. Arabi, S. Boutorabi, Mater. Sci. Tech. Ser., 2012, vol. 28, pp. 1470-1478.

A. Doroudi, A. Dastgheib, H. Omidvar, J. Manuf. Process., 2020, vol. 53, pp. 213-222.

S. Shakerin, H. Omidvar, S.E. Mirsalehi, Mater. Des., 2016, vol. 89, pp. 611-619.

A.D. Jamaloei, A. Khorram, A. Jafari, J. Manuf. Process., 2017, vol. 29, pp. 447-457.

M. Pouranvari, A. Ekrami, A. Kokabi, J. Alloy. Compd., 2013, vol. 563, pp. 143-149.

W. Gale, E. Wallach, Metall. Mater. Trans. A., 1991, vol. 22, pp. 2451-2457.

A. Doroudi, A.E. Pilehrood, M. Mohebinia, A. Dastgheib, A. Rajabi, H. Omidvar, J. Mater. Res. Technol., 2020, vol. 9, pp. 10355-10365.

A. Ghoneim, O. Ojo, Mater. Charact., 2011, vol. 62, pp. 1-7.

M. Pouranvari, Mater. Sci. Tech. Ser., 2015, vol. 31, pp. 1773-1780.

F. Arhami, S.E. Mirsalehi, Metall. Mater. Trans. A., 2018, vol. 49, PP. 6197-6214.

A. Doroudi, A. Shamsipur, H. Omidvar, M. Vatanara, J. Manuf. Process., 2019, vol. 38, pp. 235-243.

M.-c. Liu, G.-m. Sheng, H.-j. He, Y.-j. Jiao, J. Mater. Process. Tech., 2017, vol. 246, pp. 245-251.

F. Arhami, S.E. Mirsalehi, A. Sadeghian, J. Mater. Process. Tech., 2019, vol. 265, pp. 219-229.

A. Malekan, M. Farvizi, S.E. Mirsalehi, N. Saito, K. Nakashima, J. Manuf. Process., 2019, vol. 47, pp. 129-140.

W.D. MacDonald, T.W. Eagar, Metal. Sci. Join., 1992, pp. 93–100.

O. Teppa, P. Taskinen, Mater. Sci. Tech. Ser., 1993, vol. 9, pp. 205-212.

A. Ghoneim, O. Ojo, Comp. Mater. Sci., 2011, vol. 50, pp. 1102-1113.

O.A. Ojo, N.L. Richards, M.C. Chaturvedi, Sci. Technol. Weld. Joi., 2004, vol. 9, pp. 532-540.

Z. Mišković, M. Jovanović, M. Gligić, B. Lukić, Vacuum., 1992, vol. 43, pp. 709-711.

F. Arhami, S.E. Mirsalehi, J. Mater. Process. Tech., 2019, vol. 266, pp. 351-362.

J. Wei, Y. Ye, Z. Sun, G. Zou, H. Bai, A. Wu, L. Liu, Metall. Mater. Trans. A., 2017, vol. 48 pp. 4622-4631.

M. Pouranvari, A. Ekrami, A. Kokabi, J. Alloy. Compd., 2009, vol. 469, pp. 270-275.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 19, 2020; accepted January 31, 2021.

Rights and permissions

About this article

Cite this article

Sadeghian, A., Mirsalehi, S.E., Arhami, F. et al. Effect of Bonding Time on Dissimilar Transient Liquid Phase (TLP) Bonding of IN939 to IN625 Superalloys: Microstructural Characterization and Mechanical Properties. Metall Mater Trans A 52, 1526–1539 (2021). https://doi.org/10.1007/s11661-021-06176-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06176-x