Abstract

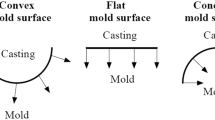

Interface heat-transfer coefficients (h 0) for permanent-mold casting (PMC) of Ti-6Al-4V were established as a function of casting surface temperature using a calibration-curve technique. Because mold geometry has a strong effect on h 0, values were determined for both of the two limiting interface types, “shrink-off” and “shrink-on.” For this purpose, casting experiments with instrumented molds were performed for cylinder- and pipe-shaped castings. The measured temperature transients were used in conjunction with two-dimensional (2-D) axisymmetric finite-element method (FEM) simulations to determine h 0(T). For the shrink-off interface type, h 0 was found to decrease linearly from 2000 to 1500 W/m2 K between the liquidus and the solidus, from 1500 to 325 W/m2 K between the solidus and the gap-formation temperature, and at a rate of 0.3 W/m2 K/K thereafter. For the shrink-on interface type, h 0 was found to increase linearly from 2000 to 2500 W/m2 K between the liquidus and the solidus temperatures, from 2500 to 5000 W/m2 K between the solidus and the gap-formation temperature, and to remain constant thereafter. The shrink-on values were up to 100 times the shrink-off values, indicating the importance of accounting for the interface geometry in FEM simulations of this process. The FEM-predicted casting and mold temperatures were found to be insensitive to certain changes in the h 0 values and sensitive to others. A comparison to published h 0 values for PMC of aluminum alloys showed some similarities and some differences.

Similar content being viewed by others

References

G.N. Colvin: Titanium ’95, P.A. Blenkinsop, W.J. Evans, and H.N. Flower, eds., Institute of Materials, London, 1996, pp. 691–701.

J. Papai and C. Mobley: Report No. ERC/NMS-887-13, Engineering Research Center for Net Shape Manufacturing, Columbus, OH, 1987.

Y. Nishida and H. Matsubara: Br. Foundryman, 1976, vol. 69, pp. 274–78.

Y. Nishida, W. Droste, and S. Engler: Metall. Trans. B, 1986, vol. 17B, pp. 833–44.

L.J.D. Sully: AFS Trans., 1976, vol. 84, pp. 735–44.

T.-G. Kim and Z.-H. Lee: Int. J. Heat Mass Transfer, 1997, vol. 40 (15), pp. 3513–25.

P.A. Kobryn and S.L. Semiatin: AFRL Materials & Manufacturing Directorate, WPAFB, OH, unpublished research, 1999.

K. Ho and R.D. Pehlke: AFS Trans., 1984, vol. 61, pp. 587–98.

S.L. Semiatin, E.W. Collings, V.E. Wood, and T. Altan: J. Eng. Industry, 1987, vol. 109, pp. 49–57.

Z.M. Hu, J.W. Brooks, and T.A. Dean: Proc Inst. Mech Eng., 1998, vol. 212, part C, pp. 485–96.

ProCAST ™ Users Manual & Technical Reference, Version 3.1.0, UES Software, Inc., Dayton, OH, 1998.

J.B. Henderson and H. Groot: Technical Report No. TPRL 1284, Thermophysical Properties Research Laboratory, Purdue University, West Lafayette, IN, 1993.

H. Groot, J. Ferrier, and D.L. Taylor: Technical Report No. TPRL 1728, Thermophysical Properties Research Laboratory, Purdue University, West Lafayette, IN, 1996.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kobryn, P.A., Semiatin, S.L. Determination of interface heat-transfer coefficients for permanent-mold casting of Ti-6Al-4V. Metall Mater Trans B 32, 685–695 (2001). https://doi.org/10.1007/s11663-001-0123-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-001-0123-6