Abstract

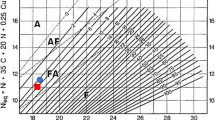

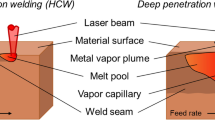

A study of laser energy transfer efficiency, melting efficiency, and deposition efficiency has been conducted for the laser-engineered net-shaping process (LENS) for H-13 tool steel and copper powder deposits on H-13 tool steel substrates. This study focused on the effects of laser deposition processing parameters (laser power, travel speed, and powder mass flow rate) on laser beam absorption by the substrate material. Measurements revealed that laser energy transfer efficiency ranged from 30 to 50 pct. Laser beam coupling was found to be relatively insensitive to the range of processing parameters tested. Melting efficiency was found to increase with increasing laser input power, travel speed, and powder mass flow rate. A dimensionless parameter model that has been used to predict melting efficiency for laser beam welding processing was investigated for the LENS process. From these results, a semiempirical model was developed specifically for the LENS processing window. Deposition efficiency was also investigated and results show that under optimum processing conditions, the maximum deposition efficiency was approximately 14 pct. A semiempirical relation was developed to estimate deposition efficiency as a function of process efficiencies and LENS processing parameters. Knowledge of LENS process efficiencies measured in this study is useful to develop accurate heat flow and solidification models for the LENS process.

Similar content being viewed by others

References

D.M. Keicher and J.E. Smugeresky: JOM, 1997, vol. 49 (5), pp. 51–54.

D.M. Keicher, W.D. Miller, J.E. Smugeresky, and J.A. Romero, Laser Engineered Net Shaping (LENS): Beyond Rapid Prototyping to Direct Fabrication, TMS-AIME, Warrendale, PA, 1998, pp. 369–77.

J.E. Smugeresky and D.M. Keicher: Laser Engineered Direct Fabrication/Manufacturing of Metals, Lasers in Surface Engineering ASM INTERNATIONAL, Metals Park, OH, 1998, pp. 505–21.

P.W. Fuerschbach: Suppl. Welding J., 1996, pp. 24–34.

P.W. Fuerschbach: The Metal Science of Joining Proc., TMS, Warrendale, PA, 1992, pp. 21–29.

J.N. DuPont and A.R. Marder: Suppl. Welding J., 1995, pp. 406–16.

W.H. Giedt, L.N. Tallerico, and P.W. Fuerschbach: Suppl. Welding J., 1989, pp. 28–32.

H.A. Fine and G.H. Geiger: Handbook on Materials and Energy Balance Calculations in Metallurgical Processes, AIME, Warrendale, PA, 1979.

P.W. Fuerschbach and D.O. MacCallum: Variation of Laser Energy Transfer Efficiency with Weld Pool Depth, ICALEO, LIA, Orlando, FL, 1995.

J. Ready: LIA Handbook of Laser Materials Processing, Magnolia Publishing, Pineville, LA, 2001, p. 180.

A. Okada: J. Jpn. Welding Soc., 1977, vol. 46 (2), pp. 53–61.

P.W. Fuerschbach and G.R. Eisler, The Effect of Very High Travel Speeds on Melting Efficiency in laser Beam Welding, SAE, 1999, pp. 824–29.

A.A. Wells: Welding J., 1952, vol. 31, (5), pp. 263s-267s.

P.W. Fuerschbach and G.A. Knorovsky: Welding J., 1991, vol. 70 (11), pp. 287s-297s.

J.N. DuPont and A.R. Marder: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 481–89.

P.W. Fuerschbach: Trends in Welding Research Proc. 4th Int. Conf., Gatlinberg, Tennessee, 1996.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Unocic, R.R., DuPont, J.N. Process efficiency measurements in the laser engineered net shaping process. Metall Mater Trans B 35, 143–152 (2004). https://doi.org/10.1007/s11663-004-0104-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-004-0104-7