Abstract

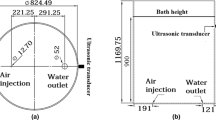

Fluid flow dynamics during ladle drainage operations of steel under isothermal and nonisothermal conditions has been studied using the turbulence shear stress transport k-ε model (SST k-ω) and the multiphase volume of fluid (VOF) model. At high bath levels, the angular velocity of the melt, close to the ladle nozzle, is small rotating anticlockwise and intense vertical-recirculating flows are developed in most of the liquid volume due to descending steel streams along the ladle vertical wall. These streams ascend further downstream driven by buoyancy forces. At low bath levels, the melt, which is close to the nozzle, rotates clockwise with higher velocities whose magnitudes are higher for shorter ladle standstill times. These velocities are responsible for the formation and development of a vortex on the bath free surface, which entrains slag into the nozzle by shear-stress mechanisms at the metal-slag interface. The critical bath level or bath height for this phenomenon is 0.35 m (in this particular ladle design) for a ladle standstill time of 15 minutes and decreases with longer ladle standstill times. At these steps, the vertical-recirculating flows are substituted by complex horizontal-rotating flows in most of the liquid volume. Under isothermal conditions, the critical bath level for vortex formation on the melt free surface is 0.20 m, which agrees very well with that determined with a 1/3 scale water model of 0.073 m. It is concluded that buoyancy forces, originated by thermal gradients, as the ladle cools, are responsible for increasing the critical bath level for vortex formation. Understanding vortex mechanisms will be useful to design simple and efficient devices to break down the vortex flow during steel draining even at very low metal residues in the ladle.

Similar content being viewed by others

References

D. Sucker, J. Reinecke, and H. Hage-Jewainski: Stahl Eisen., 1985, vol. 105, pp. 765–69.

K. Haindle: Proc. Int. Assoc. for Hydraulic Research, NRC, Ottawa, Ontano, Canada, 1959, pp. 1–17.

S.C. Koria and U. Kanth: Steel Res., 1994, vol. 5, pp. 1–8.

G. Hasall, D.P. Jackman, and R.J. Hawkins: Ironmaking and Steelmaking, 1991, vol. 18, pp. 359–69.

H. Porto Pimenta, G.A. Valadares, and G.C. Beligoni: 11th Steelmaking Seminar Proc., Argentinean Institute of Iron and Steel, San Nicolas, Argentina, 1887, pp. 199–210.

R. Sankanarayan and R.I.L. Guthrie: Ironmaking and Steelmaking, 2002, vol. 29, pp. 147–53.

R. Sankanarayan and R.I.L. Guthrie: Proc. Int. Symp. on “Developments in Ladle Steelmaking and Continuous Casting,” CIM-TMS, Montreal, Quebec, Canada, 1990, pp. 66–87.

R. Sankanarayan and R.I.L. Guthrie: ISS Steelmaking Conf., 1992, vol. 75, pp. 655–64.

P. Hammerschmidt, K.A. Tacke, H. Popper, L. Weber, and K. Schwerdtfeger: Ironmaking and Steelmaking, 1984, vol. 11, pp. 332–39.

R. Steffen: Proc. Int. Conf. On Secondary Metallurgy, RWH, Munich, Germany, 1987, pp. 547–52.

P. Andrzejewski, A. Diener, and W. Pluschkell: Steel Res., 1987, vol. 58, pp. 547–52.

P.R. Austin, J.M. Camplin, J. Herbertson, and I.J. Taggart: Iron Steel Inst. Jpn. Int., 1992, vol. 32, pp. 196–202.

C.E. Grip, H.O. Lampinen, M. Lundqvist, and S. Videhault: Iron Steel Inst. Jpn. Int., 1996, vol. 36, pp. S211–14.

C.E. Grip, L. Jonsson, and P. Jonsson: Iron Steel Inst. Jpn. Int., 1997, vol. 37, pp. 1081–90.

C.E. Grip. L. Jonsson, P. Jonsson, and K.O. Jonsson: Iron Steel Inst. Jpn. Int., 1999, vol. 39, pp. 715–21.

S. Ganguly and S. Chakraborty: Iron Steel Inst. Jpn. Int., 2004, vol. 44, pp. 537–46.

Y. Pan and B. Bjorkman: Iron Steel Inst. Jpn. Int., 2002, vol. 42, pp. 53–62.

Y. Pan and B. Bjorkman: Iron Steel Inst. Jpn. Int., 2002, vol. 42, pp. 614–23.

W.P. Jones and B.E. Launder: Int. J. Heat Mass Transfer, 1972, vol. 15, pp. 301–14.

J. Szekely: Fluid Flow Phenomena in Metals Processing, Academic Press, New York, NY, 1979, pp. 64–174.

D.C. Wilcox: Turbulence Modelling for CFD, 2nd ed., La Cañada Industries, La Cañada, CA, USA, 2002, pp. 123–25.

G. Solorio-Diaz, R.D. Morales, J. Palafox-Ramos, L Garcia-Demedices, and J. Palafox-Ramos: Iron Steel Inst. Jpn. Int., 2004, vol. 44, pp. 1024–32.

F. Menter: AIAA J., 1994, vol. 32, pp. 1598–1605.

J.H. Ferziger and M. Peric: Computational Methods for Fluid Dynamics, Springer, London, 2002, pp. 381–96.

J.U. Brackbill, D.D. Kothe, and C. Zemach: J. Comp. Phys., 1992, vol. 100, pp. 335–54.

B.E. Launder, G.J. Reece, and W. Rodi: J. Fluid Mech., 1975, vol. 68, Part 3, pp. 537–66.

S.B. Pope: Turbulent Flows, Cambridge University Press, London, 2000, pp. 387–462.

Thermophysical Properties of Molten Iron Alloys, Iron and Steel Institute of Japan, 1982, Tokyo.

J. Szekely: Rate Phenomena in Process Metallurgy, John Wiley & Sons, New York, NY, 1972, pp. 329–35.

J.D. Anderson: Computational Fluid Dynamics, McGraw-Hill Inc., New York, NY, 1995, pp. 37–93.

T. Chung: Computational Fluid Dynamics, Cambridge University Press, London, 2002, pp. 218–30.

R. Issa: J. Comp. Phys., 1985, vol. 62, pp. 40–65.

R. Issa, A.D. Gossman, and A.P. Wilkins: J. Comp. Phys., 1991, vol. 93, pp. 388–410.

FLUENT Inc., Lebanon, NH, 2004.

O. Davila, R.D. Morales, J. Palafox, L. Ferro, L. Flores, J.A. Carranza, and H. Rodroguez-Hernandez: Research Report of Ladle Drain Dynamics in 2004 for Tubos de Acero de Mexico (TAMSA). Research developed at IPN-ESIQIE Ed 7 UPALM, Col. Zacatenco Mexico D/F. C07738, unpublished research, 2005.

M. Dubke and K. Schwerdtfeger: Ironmaking and Steelmaking, 1990, vol. 17, pp. 184–92.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Davila, O., Garcia-Demedices, L. & Morales, R.D. Mathematical simulation of fluid dynamics during steel draining operations from a ladle. Metall Mater Trans B 37, 71–87 (2006). https://doi.org/10.1007/s11663-006-0087-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-006-0087-7