Abstract

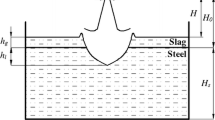

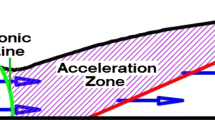

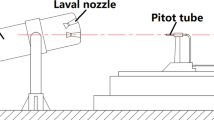

Supersonic oxygen jets are used in steelmaking and other different metal refining processes, and therefore, the behavior of supersonic jets inside a high temperature field is important for understanding these processes. In this study, a computational fluid dynamics (CFD) model was developed to investigate the effect of a high ambient temperature field on supersonic oxygen jet behavior. The results were compared with available experimental data by Sumi et al. and with a jet model proposed by Ito and Muchi. At high ambient temperatures, the density of the ambient fluid is low. Therefore, the mass addition to the jet from the surrounding medium is low, which reduces the growth rate of the turbulent mixing region. As a result, the velocity decreases more slowly, and the potential core length of the jet increases at high ambient temperatures. But CFD simulation of the supersonic jet using the k−ε turbulence model, including compressibility terms, was found to underpredict the potential flow core length at higher ambient temperatures. A modified k-ε turbulence model is presented that modifies the turbulent viscosity in order to reduce the growth rate of turbulent mixing at high ambient temperatures. The results obtained by using the modified turbulence model were found to be in good agreement with the experimental data. The CFD simulation showed that the potential flow core length at steelmaking temperatures (1800 K) is 2.5 times as long as that at room temperature. The simulation results then were used to investigate the effect of ambient temperature on the droplet generation rate using a dimensionless blowing number.

Similar content being viewed by others

Abbreviations

- a :

-

Sound speed (m/s)

- C P :

-

Specific heat (J/kg K)

- d :

-

Nozzle diameter (m)

- E :

-

Total energy (J)

- F :

-

Volumetric gas flow rate (Nm3/s)

- g:

-

Gravitational constant (m/s2)

- k :

-

Turbulent kinetic energy (m2/s2)

- K :

-

Thermal conductivity (W/mk)

- l :

-

Turbulence length scale (m)

- M τ :

-

Turbulence Mach number

- N B :

-

Blowing number

- Pr t :

-

Turbulent Prandtl number

- P :

-

Pressure (Pa)

- q :

-

Conduction heat flux (W/m2)

- R :

-

Droplet generation rate (Kg/s)

- \( r_{1/2} \) :

-

Width of the half value of axial velocity (m)

- S :

-

Mean shear rate (s−1)

- S p :

-

Spreading rate

- T :

-

Mean temperature (K)

- t′:

-

Fluctuating component of temperature (K)

- T t :

-

Total temperature (K)

- U :

-

Mean velocity (m/s)

- u :

-

Fluctuating velocity (m/s)

- ρ :

-

Density (kg/m3)

- μ :

-

Molecular viscosity (Ns/m2)

- μ t :

-

Turbulent viscosity (Ns/m2)

- ε :

-

Turbulence dissipation rate (m2/s3)

- σ :

-

Surface tension (N/m)

- a:

-

Ambient

- e:

-

Exit

- G:

-

Gas

- L:

-

Liquid

References

B. Deo and R. Boom: Fundamentals of Steelmaking Metallurgy, Prentice Hall, Upper Saddle River, NJ, 1993.

Subagyo, G.A. Brooks, K.S. Coley, and G.A. Irons: ISIJ Int., 2003, vol. 43, pp. 983–89.

P. McGee and G.A. Irons: Iron Steelmaker, 2002, vol. 29, pp. 59-68.

J.M. Luomala, T.L.J. Fabritius, E.O. Virtanen, T.P. Siivola, and J.J. Harkki: ISIJ Int., 2002, vol. 42, pp. 944–49.

K.D. Peaslee and D.G.C. Robertson: EPD Congr. Proc., San Francisco, CA, 1994, pp. 1129-45.

B. Allemand, P. Bruchet, C. Champinot, S. Melen, and F. Porzucek: Rev. Metall., 2001, vol. 98, pp. 571-87.

R. Imai, K. Kawakami, S. Miyoshi, and S. Jinbo: Nippon Kokan Technical Report-Overseas, 1968, vol. 8, pp. 9-18.

I. Sumi, Y. Kishimoto, Y. Kikichi, and H. Igarashi: ISIJ Int., 2006, vol. 46, pp. 1312-17.

Y. Tago and Y. Higuchi: ISIJ Int., 2003, vol. 43, pp. 209-15.

J.C. Lau, P.J. Morris, and M.J. Fisher: J. Fluid Mech., 1979, vol. 93, pp. 1-27.

K. Naito, Y. Ogawa, T. Inomoto, S. Kitamura, and M. Yano: ISIJ Int., 2000, vol. 40, pp. 23-30.

H. Katanoda, Y. Miyazato, M. Masuda, and K. Matsu: The 10th Int. Symp. on Flow Visualization, Kyoto, Japan, 2002,

D. Papamoschou and A. Roshko: J. Fluid Mech., 1988, vol. 197, pp. 453- 77.

B.E. Launder and D.B. Spalding: Computer Methods in Applied Mechanics and Engineering, 1974, vol. 3, pp. 269-89.

S.B. Pope: AIAA J., 1978, vol. 16, pp. 279-81.

S. Sarkar, G. Erlebacher, M.Y. Hussaini, and H.O. Kreiss: J. Fluid Mech., 1991, vol. 227, pp. 473-95.

S. Heinz: Physics of Fluids, 2003, vol. 15, pp. 3580-83.

K.S. Abdol-Hamid, S.P. Pao, S.J. Massey, and A. Elmiligui: ASME J. Fluids Eng., 2004, vol. 126, pp. 844-50.

S. Ito and I. Muchi: Tetsu-To-Hagane, 1969, vol. 55, pp. 1152-63.

D.C. Wilcox: Turbulence Modelling for CFD, 2nd ed., DCW Industries, La Canada Flintridge, CA, 1998.

J.M. Seiner, M.K. Ponton, B.J. Jansen, and N.T. Lagen: DGLR/AIAA 14th Aeroacoustics Conference Proceedings, Aachen, Germany, 1992.

T. Nonomura and K. Fujji: AIAA Applied Aerodynamics Conf., 2008

Y.A. Cengel and J.M. Cimbala: Fluid Mechanics: Fundamentals and Applications, McGraw Hill, New York, NY, 2006.

AVL Fire: CFD Solver v8.5 Manual, AVL Fire, Graz, Austria, 2006.

S.V. Patankar and D.B. Spalding: Int. J. Heat Mass Transfer, 1972, vol. 15, pp. 1787-806.

S.B. Pope: Turbulent Flows, Cambridge University Press, Cambridge, MA, 2000.

R.I.L. Guthrie: Engineering in Process Metallurgy, Oxford University Press, New York, NY, 1989.

N. Dogan, G. Brooks, and M.A. Rhamdhani: ISIJ Int., 2009, vol. 49, pp. 24-28.

Acknowledgment

The authors would like to thank One Steel, Melbourne for their financial support and useful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 16, 2009.

Rights and permissions

About this article

Cite this article

Alam, M., Naser, J. & Brooks, G. Computational Fluid Dynamics Simulation of Supersonic Oxygen Jet Behavior at Steelmaking Temperature. Metall Mater Trans B 41, 636–645 (2010). https://doi.org/10.1007/s11663-010-9341-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-010-9341-0