Abstract

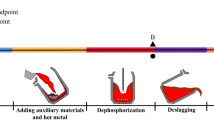

A thermodynamic model for calculating the phosphorus distribution ratio between top–bottom combined blown converter steelmaking slags and molten steel has been developed by coupling with a developed thermodynamic model for calculating mass action concentrations of structural units in the slags, i.e., CaO-SiO2-MgO-FeO-Fe2O3-MnO-Al2O3-P2O5 slags, based on the ion and molecule coexistence theory (IMCT). Not only the total phosphorus distribution ratio but also the respective phosphorus distribution ratio among four basic oxides as components, i.e., CaO, MgO, FeO, and MnO, in the slags and molten steel can be predicted theoretically by the developed IMCT phosphorus distribution ratio prediction model after knowing the oxygen activity of molten steel at the slag–metal interface or the Fe t O activity in the slags and the related mass action concentrations of structural units or ion couples in the slags. The calculated mass action concentrations of structural units or ion couples in the slags equilibrated or reacted with molten steel show that the calculated equilibrium mole numbers or mass action concentrations of structural units or ion couples, rather than the mass percentage of components, can present the reaction ability of the components in the slags. The predicted total phosphorus distribution ratio by the developed IMCT model shows a reliable agreement with the measured phosphorus distribution ratio by using the calculated mass action concentrations of iron oxides as presentation of slag oxidation ability. Meanwhile, the developed thermodynamic model for calculating the phosphorus distribution ratio can determine quantitatively the respective dephosphorization contribution ratio of Fe t O, CaO + Fe t O, MgO + Fe t O, and MnO + Fe t O in the slags. A significant difference of dephosphorization ability among Fe t O, CaO + Fe t O, MgO + Fe t O, and MnO + Fe t O has been found as approximately 0.0 pct, 99.996 pct, 0.0 pct, and 0.0 pct during a combined blown converter steelmaking process, respectively. There is a great gradient of oxygen activity of molten steel at the slag–metal interface and in a metal bath when carbon content in a metal bath is larger than 0.036 pct. The phosphorus in molten steel beneath the slag–metal interface can be extracted effectively by the comprehensive effect of CaO and Fe t O in slags to form 3CaO·P2O5 and 4CaO·P2O5 until the carbon content is less than 0.036 pct during a top–bottom combined blown steelmaking process.

Similar content being viewed by others

Abbreviations

- A :

-

constant (–)

- a i :

-

activity of components i in molten steel or in slags (–)

- \( a_{{{\text{O, (Fe}}_{t} {\text{O)}} - [ {\text{O]}}}} \) :

-

calculated oxygen activity of molten steel at slag–metal interface based on (Fe t O)–[O] equilibrium (–)

- \( a_{{{\text{O, [C]}} - [ {\text{O]}}}} \) :

-

calculated oxygen activity of molten steel based on [C]–[O] equilibrium (–)

- \( a_{{{\text{O, (Fe}}_{t} {\text{O)}} - [ {\text{O]}}}}^{{{\text{slag}} - {\text{metal interface}}}} \) :

-

calculated oxygen activity of molten steel at slag–metal interface based on (Fe t O)–[O] equilibrium with replacing \( a_{{{\text{Fe}}_{t} {\text{O}}}} \) by \( N_{{{\text{Fe}}_{t} {\text{O}}}} \) (–)

- \( a_{{{\text{O, [C]}} - [ {\text{O]}}}}^{\text{bath}} \) :

-

calculated oxygen activity of bulk molten steel based on [C]–[O] equilibrium (–)

- B :

-

constant (–)

- b i :

-

mole number of component i in 100-g slags (mol)

- \( C_{{{\text{S}}^{ 2- } }} \) :

-

sulfide capacity of the slags (–)

- \( e_{i}^{j} \) :

-

interaction coefficient of component j on component i in molten steel (–)

- f i :

-

activity coefficient of component i in molten steel (–)

- \( \Updelta_{\text{r}} G_{{{\text{m, }}i}}^{\Uptheta } \) :

-

standard molar Gibbs free energy change of forming complex molecule i in slags (J/mol)

- \( \Updelta_{\text{fus}} G_{{{\text{m, }}i}}^{\Uptheta } \) :

-

standard molar Gibbs free energy change of melting component i or structural unit i from solid to liquid (J/mol)

- \( \Updelta_{\text{sol}} G_{{{\text{m, }}i}}^{\Uptheta } \) :

-

standard molar Gibbs free energy change of dissolving component i or structural unit i into slags (J/mol)

- (pct i):

-

mass percentage of component i in the slags (mass pct)

- [pct i]:

-

mass percentage of component i in molten steel (mass pct)

- \( K_{i}^{\Uptheta } \) :

-

equilibrium constant of chemical reaction for forming component i or structural unit i (–)

- \( K_{i}^{'\Uptheta } \) :

-

equilibrium constant of chemical reaction for forming component i or structural unit i (–)

- \( L_{\text{P}} \) :

-

phosphorus distribution ratio between slags and molten steel (–)

- \( L_{\text{P}}^{'} \) :

-

calculated phosphorus distribution ratio between slags and molten steel based on molten steel oxidization ability with \( a_{{{\text{O, (Fe}}_{t} {\text{O)}} - [ {\text{O]}}}} \) by IMCT model (–)

- \( L_{\text{S}} \) :

-

sulfur distribution ratio between slags and molten steel (–)

- \( L_{{{\text{P, }}i}} \) :

-

calculated respective phosphorus distribution ratio of generated structural unit i containing P2O5 in slags based on slag oxidization ability by IMCT model (–)

- \( L_{{{\text{P, }}i}}^{'} \) :

-

calculated respective phosphorus distribution ratio of generated structural unit i containing P2O5 in slags based on molten steel oxidization ability (–)

- \( L_{\text{P, calculated}}^{\text{IMCT}} \) :

-

calculated total phosphorus distribution ratio between slags and molten steel based on slag oxidization ability by IMCT model (–)

- \( L_{\text{P, calculated}}^{{ ' {\text{ IMCT}}}} \) :

-

calculated total phosphorus distribution ratio between slags and molten steel based on molten steel oxidization ability by IMCT model (–)

- \( L_{\text{P, measured}} \) :

-

measured phosphorus distribution ratio (–)

- \( L_{\text{P, calculated}}^{{ \, a_{{{\text{Fe}}_{t} {\text{O}}}} , {\text{ IMCT}}}} \) :

-

calculated total phosphorus distribution ratio between slags and molten steel based on slag oxidization ability with \( a_{{{\text{Fe}}_{t} {\text{O}}}} \) from \( a_{{{\text{O, [C]}} - [ {\text{O]}}}} \) via [C]–[O] equilibrium by IMCT model (–)

- \( L_{\text{P, calculated}}^{{N_{{{\text{Fe}}_{t} {\text{O}}}} , {\text{ IMCT }}}} \) :

-

calculated total phosphorus distribution ratio between slags and molten steel based on slag oxidization ability with \( N_{{{\text{Fe}}_{t} {\text{O}}}} \) from (Fe t O)–[O] equilibrium by IMCT model (–)

- \( L_{\text{P, calculated}}^{{ ' { }a_{{{\text{O, (Fe}}_{t} {\text{O)}} - [ {\text{O]}}}}^{{}} , {\text{ IMCT }}}} \) :

-

calculated total phosphorus distribution ratio between slags and molten steel based on molten steel oxidization ability with \( a_{{{\text{O, (Fe}}_{t} {\text{O)}} - [ {\text{O]}}}} \) from (Fe t O)–[O] equilibrium by IMCT model (–)

- \( L_{\text{P, calculated}}^{{ ' { }a_{{{\text{O, [C]}} - [ {\text{O]}}}} , {\text{ IMCT}}}} \) :

-

calculated total phosphorus distribution ratio between slags and molten steel based on molten steel oxidization ability with \( a_{{{\text{O, [C]}} - [ {\text{O]}}}} \) from [C]–[O] equilibrium by IMCT model (–)

- \( L_{{{\text{P, }}i , {\text{ calculated}}}}^{\text{IMCT}} \) :

-

calculated respective phosphorus distribution ratio between generated structural unit i containing P2O5 in slags and molten steel based on slag oxidization ability by IMCT model from calculated data (–)

- \( L_{{{\text{P, }}i , {\text{ measured}}}}^{\text{IMCT}} \) :

-

calculated respective phosphorus distribution ratio of generated structural unit i containing P2O5 in slags based on slag oxidization ability by IMCT model from measured data (–)

- \( L_{\text{P, calculated}}^{i} \) :

-

calculated phosphorus distribution ratio between slags and molten steel by model i (–)

- Me:

-

metal (–)

- MeO:

-

metal oxide in slags (–)

- M i :

-

molecular mass of element i or component i (g/mol)

- \( n_{i}^{0} \) :

-

mole number of component i in 100-g slags (mol)

- n i :

-

equilibrium mole number of structural unit i or ion couple i in 100-g slags (mol)

- N i :

-

mass action concentrations of structural unit i or ion couple i in the slags (–)

- \( \sum n_{i} \) :

-

total equilibrium mole number of all structural units in 100-g slags (mol)

- R :

-

gas constant (8.314 J/(mol K))

- T :

-

absolute temperature (K)

- \( [{\text{pct}}\,{\text{O}}]_{{[{\text{C}}] - [ {\text{O]}}}}^{{}} \) :

-

mass percentage of oxygen in molten steel based on [C]–[O] equilibrium (mass pct)

- \( [{\text{pct O}}]_{{ ( {\text{Fe}}_{t} {\text{O)}} - [ {\text{O]}}}}^{{}} \) :

-

mass percentage of oxygen in molten steel based on (Fe t O)–[O] equilibrium (mass pct)

- \( [{\text{pct O}}]_{{ ( {\text{Fe}}_{t} {\text{O)}} - [ {\text{O]}}}}^{{{\text{slag}} - {\text{metal interface}}}} \) :

-

calculated oxygen content of molten steel at slag–metal interface based on (Fe t O)–[O] equilibrium with replacing \( a_{{{\text{Fe}}_{t} {\text{O}}}} \) by \( N_{{{\text{Fe}}_{t} {\text{O}}}} \) (–)

- \( [{\text{pct O}}]_{{[{\text{C}}] - [ {\text{O]}}}}^{\text{bath}} \) :

-

calculated oxygen content of molten steel in metal bath based on [C]–[O] equilibrium (–)

- \( \Uplambda \) :

-

optical basicity of the slags (–)

- \( \Uplambda_{i} \) :

-

optical basicity of component i in the slags (–)

- \( \mu_{{i({\text{s}})}}^{ * } \) :

-

chemical potential of component i as solid (J/mol)

- \( \mu_{{i({\text{l}})}}^{ * } \) :

-

chemical potential of component i as liquid (J/mol)

- \( \mu_{i}^{\Uptheta } \) :

-

standard chemical potential of dissolved component i in slags (J/mol)

- ci :

-

complex molecule i (–)

References

T.B. Winkler and J. Chipman: Trans. AIME, 1946, vol. 167, pp. 111-33.

K. Balajiva, A.G. Quarrell, and P. Vajragupta: J. Iron Steel Inst., 1946, vol. 153, pp. 115-50.

F.D. Richardson: Physical Chemistry of Melts in Metallurgy, vol. 1, Academic Press, London, UK, 1974, pp. 87-135.

C. Nassaralla and R.J. Fruehan: Metall. Mater. Trans. B, 1992, vol. 23B, pp. 117-23.

A.T. Morales and R.J. Fruehan: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 1111-18.

S. Basu, A.K. Lahiri, S. Seetharaman, and J. Halder: ISIJ Int., 2007, vol. 47, no. 5, pp. 766-68.

S. Basu, A.K. Lahiri, and S. Seetharaman: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 357-66.

8. S. Basu, A.K. Lahiri, and S. Seetharaman: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 623-30.

K. Ide and R.J. Fruehan: Iron Steelmaker, 2000, vol. 27, no. 12, pp. 65-70.

G.W. Healy: J. Iron Steel Inst., 1970, vol. 208, pp. 664-68.

H. Suito and R. Inoue: ISIJ Int., 1984, vol. 24, no. 1, pp. 40-46.

H. Suito, R. Inoue, and M. Takada: ISIJ Int., 1981, vol. 21, no. 4, pp. 250-59.

I.D. Sommerville, X.F. Zhang, and J.M. Toguri: Trans. Iron Steel Soc., 1985, vol. 6, pp. 29-42.

K. Balajiva, A.Q. Quarrel, and P. Vajragupta: J. Iron Steel Inst., 1946, vol. 153, pp. 115-45.

S.K. Choudhary, S.N. Lenka, and A. Ghosh: Ironmaking Steelmaking, 2007, vol. 34, no. 4, pp. 343-49.

B. Deo, J. Halder, B. Snoeijer, A. Overbosch, and R. Boom: Ironmaking Steelmaking, 2005, vol. 32 (1), pp. 54–60.

W.H. Niekerk and R.J. Dippenaar: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 147-53.

M. Ishikawa: ISIJ Int., 2006, vol. 46, no. 4, pp. 530-38.

J. Pal, S. Ghorai, D.P. Singh, A.K. Upadhyay, S. Ghosh, D. Ghosh, and D. Bandyopadhyay: ISIJ Int., 2010, vol. 50, no. 1, pp. 105-14.

J. Zhang: Computational Thermodynamics of Metallurgical Melts and Solutions, Metallurgical Industry Press, Beijing, China, 2007.

J. Zhang: Acta Metall. Sinica (English Lett.), 2001, vol. 14, no. 3, pp. 177-90.

J. Zhang: J. Univ. Sci. Technol. Beijing, 2002, vol. 9, no. 2, pp. 90-98.

J. Zhang: Rare Metals, 2004, vol. 23, no. 3, pp. 209-13.

X.M. Yang, J.S. Jiao, R.C. Ding, C.B. Shi, and H.J. Guo: ISIJ Int., 2009, vol. 49, no. 12, pp. 1828-37.

C.B. Shi, X.M. Yang, J.S. Jiao, C. Li, and H.J. Guo: ISIJ Int., 2010, vol. 50, no. 10, pp. 1362-72.

X.M. Yang, C.B. Shi, M. Zhang, G.M. Chai, and F. Wang: unpublished research.

Verein Deutscher Eisenhüttenleute, Slag Atlas, 2nd ed., Woodhead Publishing Limited, Abington, Cambridge, UK, 1995.

J.X. Chen: Handbook of Common Figures, Tables and Data for Steelmaking, Metallurgical Industry Press, Beijing, China, 1984.

E.T. Turkdogan: Physical Chemistry of High Temperature Technology, Academic Press, New York, NY, 1980, pp. 8-12.

R.H. Rein and J. Chipman: Trans. Met. Soc. AIME, 1965, vol. 233, no. 2, pp. 415-25.

H. Gaye and J. Welfringer: Proc. Second International Symposium on Metallurgical Slags and Fluxes, H.A. Fine and D.R. Gaskell, eds., Lake Tahoe, NV, TMS–AIME, 1984, pp. 357–75.

K. Narita and K. Shinji: Kobe Steel Engin. Rep., 1969, vol. 19, pp. 25-42.

The Japan Society for the Promotion of Science, The 19th Committee on Steelmaking: Steelmaking Data Sourcebook, Gordon and Breach Science Publishers, New York, NY, 1988.

S. Ban-ya, A. Chiba, and A. Hirosaka: Tetsu-to-Hagané, 1980, vol. 66, no. 10, pp. 1484-93.

M. Timucin and A. Muan: J. Am. Ceram. Soc., 1992, vol. 75, no. 6, pp. 1399-1406.

I. Barin, O. Knacke, and O. Kubaschewski: Thermochemical Properties of Inorganic Substances, Supplement, Springer-Verlag, New York, NY, 1977, pp. 392-445.

O. Knacke, O. Kubaschewski, and K. Hesselmann: Thermochemical Properties of Inorganic Substances, 2nd ed., Springer–Verlag, New York, NY, 1991, pp. 47, 1136, 1836.

J.B. Bookey: J Iron Steel Inst., 1952, vol. 172, pp. 61-66.

S.K. Wei: Thermodynamics of Metallurgical Processes (series book of modern metallurgy), Shanghai Scientific & Technical Publishers, Shanghai, China, 1980, pp. 52, 292, 396–98.

R.G. Ward: An Introduction to the Physical Chemistry of Iron and Steel-Making, Edward Arnold Publishers Ltd., London, UK, 1962, pp. 122-40.

J. Zhang: J. Beijing Univ. Iron Steel Technol., 1986, vol. 8, pp. 1-6.

J. Zhang: J. Beijing Univ. Iron Steel Technol., 1988, vol. 10, pp. 1-6.

P. Wang, T.W. Ma, and J. Zhang: Iron Steel, 1996, vol. 31, pp. 27-31.

J. Zhang and C. Wang: J. Univ. Sci. Technol. Beijing, 1991, vol. 13, pp. 214-21.

J. Zhang and W.X. Yuan: J. Univ. Sci. Technol. Beijing, 1995, vol. 17, pp. 418-23.

J. Zhang: Acta Metall. Sinica, 1998, vol. 34, pp. 742-52.

J. Zhang and P. Wang: CALPHAD, 2001, vol. 25, pp. 343-54.

H. Guo, Y.T. Hu, D.Q. Cang, Y. Jin, L.X. Wang, X.L. Cheng, H. Bai, and Y.B. Zong: Chinese Chem. Lett., 2010, vol. 21, pp. 229-33.

J.Y. Zhang: Metallurgical Physicochemistry, Metallurgical Industry Press, Beijing, China, 2004, pp. 42-43.

E.T. Turkdogan: J Iron Steel Inst., 1953, vol. 175, pp. 398-401.

H. Suito and R. Inoue: Trans. ISIJ, 1984, vol. 24, no. 4, pp. 301-07.

G.K. Sigworth and J.F. Elliott: Met. Sci., 1974, vol. 8, no. 9, pp. 298-310.

D.J. Sosinsky and I.D. Sommerville: Metall. Trans. B, 1986, 17B, 331-37.

T. Nakamura, Y. Ueda, and J. M. Toguri: Proc. Third International Conference on Metallurgical Slags and Fluxes, The Institute of Metals, London, UK, 1988, pp. 146-49.

K.C. Mills and S. Sridhar: Ironmaking Steelmaking, 1999, vol. 26, pp. 262-68.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 20, 2010.

Rights and permissions

About this article

Cite this article

Yang, XM., Duan, JP., Shi, CB. et al. A Thermodynamic Model of Phosphorus Distribution Ratio between CaO-SiO2-MgO-FeO-Fe2O3-MnO-Al2O3-P2O5 Slags and Molten Steel during a Top–Bottom Combined Blown Converter Steelmaking Process Based on the Ion and Molecule Coexistence Theory. Metall Mater Trans B 42, 738–770 (2011). https://doi.org/10.1007/s11663-011-9491-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9491-8