Abstract

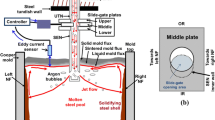

Undesirable flow variations can cause severe instabilities at the interface between liquid mold flux and molten steel across the mold top-region during continuous steel casting, resulting in surface defects in the final products. A three-dimensional Large Eddy Simulation (LES) model using the volume of fluid method for the slag and molten steel phases is validated with plant measurements, and applied to gain new insights into the effects of nozzle port angle on transient flow, top slag/steel interface movement, and slag behavior during continuous slab casting under nominally steady conditions. Upward-angled ports produce a single-roll flow pattern with lower surface velocity, due to rapid momentum dissipation of the spreading jet. However, strong jet wobbling from the port leads to greater interface variations. Severe level drops allow easy entrapment of liquid flux by the solidifying steel shell at the meniscus. Sudden level rises may also be detrimental, leading to overflow of the solidified meniscus region. Downward-angled ports produce a classic double-roll pattern with less jet turbulence and a more stable interface everywhere except near the narrow faces. Finally, the flow patterns, surface velocity, and level predicted from the validated LES model are compared with steady-state standard k-ε model predictions.

Similar content being viewed by others

References

L.C. Hibbeler and B. G. Thomas: Iron Steel Technol., 2013, vol. 10(10), pp. 121-136.

T. Teshima, M. Osame, K. Okimoto and Y. Nimura: Proc. of 71th Steelmaking Conf., The Iron and Steel Society, London, UK, 1988, pp. 111–118.

M. Iguchi, J. Yoshida, T. Shimizu, and Y. Mizuno: ISIJ Int., 2000, vol. 40, pp. 685-691.

R. Hagemann, R. Schwarze, H. P. Heller, and P. R. Scheller: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 80-90.

H. Shin, S. Kim, B. G. Thomas, G. Lee, J. Park, and J. Sengupta: ISIJ Int., 2006, vol. 46, pp. 1635-1644.

J. Sengupta, B. G. Thomas, H. Shin, G. Lee, and S. Kim: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1597-1611.

Z. Liu, B. Li, and M. Jiang: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 675-697.

Z. Liu, F. Qi, B. Li, and M. Jiang: J. Iron Steel Res. Int., 2014, vol. 21, pp. 1081-1089.

Z. Liu, Z. Sun, and B. Li: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 1248-1267.

S-M. Cho, S-H. Kim, R. Chaudhary, B. G. Thomas, H-J. Shin, W-Y. Choi, S-K. Kim: Iron Steel Technol., 2012, vol.9, pp. 85-95.

R. Chaudhary, G-G. Lee, B. G. Thomas, S-M. Cho, S-H. Kim, and O-D. Kwon: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 300-315.

C. Ojeda, B. G. Thomas, J. Barco, and J. L. Arana: Proc. of AISTech 2007, Assoc. Iron Steel Technology, Warrendale, PA, USA, 2007, vol. 1, pp. 269–84.

J. Sengupta, C. Ojeda, and B. G. Thomas: Int. J. Cast Met. Res., 2009, vol. 22, pp. 8-14.

S-M. Cho, B. G. Thomas, and S-H. Kim: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 3080-3098.

S. Kunstreich, P. H. Dauby, S.-K. Baek, and S.-M. Lee: Proc. of 5th European Continuous Casting Conf., Nice, France, 2005, pp. 37–44.

P. H. Dauby: Rev. Metall., 2012, vol. 109, pp. 113-136.

K. Jin, S. P. Vanka, and B. G. Thomas: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 162-178.

H. Bai and B. G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 269-284.

Z. Liu, B. Li, M. Jiang, and F. Tsukihashi: ISIJ Int., 2013, vol. 53, pp. 484-492.

Z. Liu, F. Qi, B. Li, and S. C. P. Cheng: Int. J. Multiphase. Flow, 2016, vol. 79, pp. 190-201.

K. Cukierski and B. G. Thomas: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 94-107.

Y. Wang, A. Dong, and L. Zhang: Steel Res. Int., 2011, vol. 82, pp. 428-439.

R. Singh, B. G. Thomas, and S. P. Vanka: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1098-1115.

B. G. Thomas, L. J. Mika, and F. M. Najjar: Metall. Mater. Trans B, 1990, vol. 21B, pp. 387-400.

F. M. Najjar, B. G. Thomas, and D. E. Hershey: Metall. Mater. Trans B, 1995, vol. 26B, pp. 749-765.

S-M. Cho, B. G. Thomas, H-J. Lee, and S-H. Kim: Iron Steel Technol., 2017, vol. 14, pp. 76-84.

I. Calderon-Ramos, R. D. Morales, and M. Salazar-Campoy: Steel Res. Int., 2015, vol. 86, pp. 1610-1621.

M. M. Salazar-Campoy, R. D. Morales, A. Nájera-Bastida, I. Calderón-Ramos, V. Cedillo-Hernández, and J. C. Delgado-Pureco: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 812-830.

R. Chaudhary, G-G. Lee, B. G. Thomas, and S-H. Kim: Metall. Mater. Trans B, 2008, vol. 39B, pp. 870-884.

C. A. Real-Ramirez, R. Miranda-Tello, L. Hoyos-Reyes, M. Reyes, and J. I. Gonzalez-Trejo: Indian J. Eng. Mater. Sci., 2012, vol. 19, pp. 179-188.

Q. Yuan: Ph. D. Thesis, University of Illinois at Urbana-Champaign, 2004.

Q. Yuan, B. G. Thomas, and S. P. Vanka: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 685-702.

R. Liu: Ph. D. Thesis, University of Illinois at Urbana-Champaign, 2015.

ANSYS FLUENT 14.5-Theory Guide, ANSYS. Inc., Canonsburg, PA, USA, 2012.

F Nicoud, F Ducros (1999) Flow Turb. Comb. 63:183-200.

A. W. Cramb and I. Jimbo: Iron Steelmaking., 1989, vol. 16, pp. 43-55.

J. Lee and K. Morita: ISIJ Int., 2002, vol. 42, pp. 588-594.

B. J. Keene: Int. Mater. Rev., 1993, vol. 38, pp. 157-192.

A Kasama, A McLean, WA Miller, Z Morita, MJ Ward (1983) Can. Metall. Q. 22:9-17.

KC Mill, YC Su (2006) Int. Mater. Rev. 51:329-351.

H. Shin: Ph.D. Thesis, POSTECH, 2006.

B. Zhao, S. P. Vanka, and B. G. Thomas: Int. J. Heat Fluid Flow, 2005, vol. 26, pp. 105-118.

R. M. McDavid and B. G. Thomas: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 672-685.

B. Xie, J. Wu, and Y. Gan: Proc. of Steelmaking Conference, ISS-AIME, Warrendale, PA, USA, 1991, pp. 647–651.

R. Liu, J. Sengupta, D. Crosbie, S. Chung, M. Trinh, and B. G. Thomas: Proc. of TMS 2011, TMS, Warrendale, PA, USA, 2011, pp. 51–58.

H. Bai and B. G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 253-267.

Q. Yuan, S. Sivaramakrishnan, S. P. Vanka, and B. G. Thomas: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 967–982.

J. M. Harman and A. W. Cramb: Proc. 79th Steelmaking Conf., The Iron and Steel Society, Warrendale, PA, USA, 1996, pp. 773–84.

H. L. F. Von Helmholtz: Monatsb. K. Preuss. Akad. Wiss. Berlin, 1868, vol. 23, pp. 215-228.

W. Thomson. (Lord Kelvin): Phil. Mag., 1871, vol. 42, No. 281, pp. 362-377.

T. Funada and D. D. Joseph: J. Fluid, 2001, vol. 445, pp. 263-283.

G-G. Lee, B. G. Thomas, S-H. Kim, H-J. Shin, S-K. Baek, C-H. Choi, D-S. Kim, and S-J. Yu: Acta Mater., 2007, vol. 55, pp. 6705-6712.

L. Zhang and Brian G. Thomas: Proc. Of XXIV National Steelmaking Symposium, Morelia, Mich, Mexico, 2003, pp. 138–183.

H-J Shin, B . G. Thomas, G-G. Lee, J-M. Park, C-H. Lee, and S-H. Kim: Proc. Materials Science and Technology (MS&T), Assoc. Iron Steel Technology, Warrendale, PA, USA, 2004, vol. II, pp. 11–26.

ASM. Jonayat and B. G. Thomas: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1842–64.

B. E. Launder and D. B. Spalding: Lectures in Mathematical Models of Turbulence. Academic Press, London, England. 1972.

S-M. Cho, S-H. Kim, and B. G. Thomas: ISIJ Int., 2014, vol. 54, pp. 845-854.

R. Chaudhary, C. Ji, B. G. Thomas, and S. P. Vanka: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 987-1007.

S-M. Cho, S-H. Kim, and B. G. Thomas: ISIJ Int., 2014, vol. 54, pp. 855-864.

R. Chaudhary, B. T. Rietow, and B. G. Thomas: Proc. Materials Science and Technology (MS&T), AIST/TMS, Pittsburgh, PA, 2009, pp. 1090–1101.

X. Jin, D. Chen, X. Xie, J. Shen, and M. Long: Steel Res. Int., 2013, vol. 84, pp. 31-39.

Acknowledgments

The authors thank POSCO for their assistance in collecting plant data and financial support (Grant No. 4.0011721.01), and Dr. Hyun-Jin Cho and Dr. Ji-Joon Kim, POSCO for help with the plant measurements. Support from the Continuous Casting Center at Colorado School of Mines, the Continuous Casting Consortium at University of Illinois at Urbana-Champaign, and the National Science Foundation GOALI grant (Grant No. CMMI 18-08731) are gratefully acknowledged. Provision of FLUENT licenses through the ANSYS Inc. academic partnership program is also much appreciated. This research is part of the Blue Waters sustained-petascale computing project, which is supported by the National Science Foundation (awards OCI-0725070 and ACI-1238993) and the state of Illinois. Blue Waters is a joint effort of the University of Illinois at Urbana-Champaign and its National Center for Supercomputing Applications.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 27, 2018.

Electronic supplementary material

Below is the link to the electronic supplementary material.

11663_2018_1439_MOESM1_ESM.avi

Supplementary material 1 Jet flow wobbling in mold center-middle plane with + 15 deg (up) ports. Supplementary material 1 (AVI 70531 kb)

11663_2018_1439_MOESM2_ESM.avi

Supplementary material 2 Jet flow wobbling in mold center-middle plane with − 30 deg (down) ports. Supplementary material 2 (AVI 71226 kb)

11663_2018_1439_MOESM3_ESM.avi

Supplementary material 3 Transient jet flow pattern and liquid-slag layer motion in the mold for + 15 deg (up) ports. Supplementary material 3 (AVI 94486 kb)

11663_2018_1439_MOESM4_ESM.avi

Supplementary material 4 Transient jet flow pattern and liquid-slag layer motion in the mold for − 30 deg (down) ports. Supplementary material 4 (AVI 86661 kb)

11663_2018_1439_MOESM5_ESM.avi

Supplementary material 5 Transient slag/steel interface profile on IR in the mold for + 15 deg (up) ports. Supplementary material 5 (AVI 43553 kb)

11663_2018_1439_MOESM6_ESM.avi

Supplementary material 6 Transient slag/steel interface profile on IR in the mold for − 30 deg (down) ports. Supplementary material 6 (AVI 46630 kb)

Appendix: Spread Angles of Jet Flow

Appendix: Spread Angles of Jet Flow

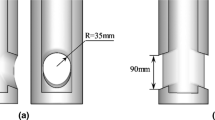

Vertical and horizontal spread angles of the jet flow at the nozzle port outlet are calculated to quantify the flow characteristics leaving the nozzle. The calculation is based on a weighted average of outward flow rate, ignoring the backflow zone where flow enters the port. Figure A1 illustrates the definition of both spread angles.

Vertical spread angle, θxy,sp is calculated as follows:

where θxy is the vertical jet angle at the nozzle port outlet surface,[25,46] θxy,upper and θxy,lower are vertical jet angles calculated from the velocity vectors leaving each region, split into upper and lower regions according to the regions of the port exit surface found above and below the center plane of the jet flow, respectively. Due to the back flow zone located in the upper part at the nozzle port outlet, the two regions are separated, based on a mass flow-rate balance of the jet as follows:

where i and j are cells in the upper and the lower port regions, respectively, (numbered according to increasing x height when calculating vertical spread angle), N is the total number of cells in the jet region with positive outflow, n is the unknown total number of cells in the lower region to be solved, and umag is the velocity magnitude in each cell in the exit plane of the nozzle port.

Horizontal spread angle, θyz,sp, is calculated in a similar manner, as follows:

where θyz is the horizontal jet angle at the nozzle port outlet surface,[25,46] θyz,IR and θyz,OR are the horizontal jet angles in each ~ half-port region, IR and OR side, respectively.

Rights and permissions

About this article

Cite this article

Cho, SM., Thomas, B.G. & Kim, SH. Effect of Nozzle Port Angle on Transient Flow and Surface Slag Behavior During Continuous Steel-Slab Casting. Metall Mater Trans B 50, 52–76 (2019). https://doi.org/10.1007/s11663-018-1439-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1439-9