Abstract

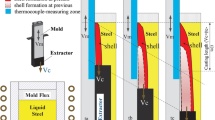

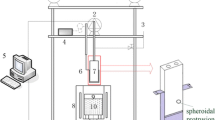

Corner transverse cracks are frequently observed on microalloyed steel slabs during continuous casting. As a solution to this problem, double phase-transformation technology could improve the ductility of the shell surface and avoid corner cracks. However, this technology requires a high cooling rate, which is difficult to reach in traditional flat plate molds (TFMs). Therefore, a novel convex structure mold (NCM) was designed to intensify corner cooling. To investigate the effects of mold design on interfacial heat transfer between the solidifying shell and mold, a thermomechanical model was developed considering the dynamic distributions of the mold slag layers and air gaps. Afterward, the interfacial heat fluxes between mold and solidifying shell obtained from the thermomechanical model were loaded on the flow, heat transfer, and solidification model to study the comprehensive influence of mold cavity design and steel flow on the shell temperature. Based on the models, the contact conditions, distributions of interfacial heat transfer media, interfacial heat fluxes, and temperatures and thicknesses of the solidifying shells were thoroughly compared between the TFM and NCM. The results show that the NCM provides a more appropriate compensation for the shell shrinkage; as a result, the thick slag layers concentrating in the corners of the TFM are flattened and homogenized in the NCM. Thicker slag layers in the TFM weaken the corner heat transfer and lead to uneven shell growth in the off-corner area. Meanwhile, the NCM could homogenize the off-corner heat transfer and increase the cooling rate of the shell corner to help implement double phase-transformation technology in the high-temperature zone of casters.

Similar content being viewed by others

References

Y. Meng, B.G. Thomas, Metall. Mater. Trans. B 34B, 685–705 (2003)

C. Li, B.G. Thomas, Metall. Mater. Trans. B 35B, 1151–1172 (2004)

J.K. Park, C. Li, B.G. Thomas, and I.V. Samarasekera: 60th Electr. Furn. Conf., San Antonio, TX, 2002, AIST, Warrendale, PA, 2002, vol. 60, pp. 669–86.

D.J. Jing, K.K. Cai, Acta Metall. Sin. 36, 403–406 (2000)

C. Li, and B.G. Thomas: ISSTech Steelmak. Conf., Indianapolis, IN, USA, 2003, ISS-AIME, Warrendale, PA, 2003, pp. 685–700.

B.G. Thomas and C. Ojeda: ISSTech Steelmak. Conf., Indianapolis, IN, USA, 2003, ISS-AIME, Warrendale, PA, 2003, pp. 295–308.

Y.M. Won, T.J. Yeo, K.H. Oh, J.K. Park, J. Choi, C.H. Yim, ISIJ Int. 38, 53–62 (1998)

R.B. Mahapatra, J.K. Brimacombe, I.V. Samarasekera, Metall. Mater. Trans. B 22B, 875–888 (1991)

J.K. Brimacombe, F. Weinberg, E.B. Hawbolt, Metall. Trans. B 10B, 279–292 (1979)

N. Yamasaki, S. Shima, K. Tsunenari, S. Hayashi, M. Doki, Y. Kato, D. Miki, T. Nakanishi, Nippon Steel Sumitomo Met. Tech. Rep. 112, 64–70 (2016)

S.N. Berdnikov, A.E. Pozin, A.A. Podosyan, A.S. Berdnikov, V.A. Mokhov, K.N. Vdovin, Steel Transl. 42, 180–182 (2012)

Z. Cai, M. Zhu, ISIJ Int. 53, 1818–1827 (2013)

J.K. Brimacombe, K. Sorimachi, Metall. Trans. B 8B, 489–505 (1977)

P. Hu, H. Zhang, M. Wang, M. Zhu, X. Zhang, Y. Zhang, and Z. Zhang: Metall Res Technol, 2015, vol. 112, 104-113.

S. Yu, M. Long, D. Chen, H. Fan, H. Yu, H. Duan, X. Xie, T. Liu, J. Mater. Process. Technol. 270, 157–167 (2019)

P. Lyu, W. Wang, X. Long, K. Zhang, E. Gao, R. Qin, Metall. Mater. Trans. B 49B, 78–88 (2017)

S.V. Filatov, A.I. Dagman, V.N. Karavaev, V.P. Glebov, G.N. Kononykhin, A.B. Kotel’nikov, A.A. Vopneruk, Metallurgist 62, 58–61 (2018)

F.J. Ma, G.H. Wen, P. Tang, X. Yu, J.Y. Li, G.D. Xu, F. Mei, Ironmak. Steelmak. 37, 73–79 (2010)

T. Kato, Y. Ito, M. Kawamoto, A. Yamanaka, T.J.I. Watanabe, ISIJ Int. 43, 1742–1750 (2003)

C. Du, J. Zhang, J. Wen, Y. Li, P. Lan, Ironmak. Steelmak. 43, 331–339 (2016)

J. Liu, G. Wen, P. Tang, Metall. Mater. Trans. B 48B, 3074–3082 (2017)

F.J. Ma, G.H. Wen, P. Tang, X. Yu, J.Y. Li, G.D. Xu, F. Mei, Ironmak. Steelmak. 37, 211–218 (2010)

Z. Niu, Z. Cai, M. Zhu, ISIJ Int. 59, 283–292 (2019)

MSC Marc, Theory and User Information (MSC Software Corporation, Newport Beach, 2016).

Z. Cai, M. Zhu, Acta Metall. Sin. 47, 671–677 (2011)

X. Liu, M. Zhu, ISIJ Int. 46, 1652–1659 (2006)

K. Liu, Y.H. Chang, Z.G. Han, J.Q. Zhang, J. Iron Steel Res. Int. 20, 38–47 (2013)

Z. Niu, Z. Cai, and M. Zhu: Ironmak. Steelmak., 2019, vol. 47, pp. 1135-47

H. Mizukami, K. Murakami, Y. Miyashita, Tetsu-to-Hagane 63, 652 (1977)

M. Uehara, I.V. Samarasekera, J.K. Brimacombe, Ironmak. Steelmak. 13, 138–153 (1986)

ANSYS Inc., ANSYS FLUENT 16.2 Theory Guide (ANSYS, Inc., Canonsburg, 2015).

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51774075, 51404061) and Fundamental Research Funds for the Central Universities of China (N182504013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 21, 2020; accepted February 8, 2021.

Rights and permissions

About this article

Cite this article

Niu, Z., Cai, Z. & Zhu, M. Effect of Mold Cavity Design on the Thermomechanical Behavior of Solidifying Shell During Microalloyed Steel Slab Continuous Casting. Metall Mater Trans B 52, 1556–1573 (2021). https://doi.org/10.1007/s11663-021-02123-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02123-8