Abstract

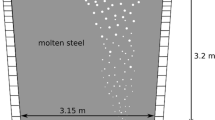

This article presents a mathematical model to describe the discontinuous flow of an isothermal liquid in packed beds, simulating in part the flow condition in and below the blast furnace cohesive zone. The model is developed based on a force balance approach to describe the discrete liquid flow and a stochastic treatment to take into account the complex packing structure. The interaction between gas and liquid flows has also been included in the governing equations, so that the localized liquid flow in a packed bed can be modeled with or without gas flow. The difference between the microscopic and macroscopic approaches is discussed, and it is argued that at this stage of development, liquid flow modeling should be conducted at the macroscopic level. Techniques for numerical solution are provided. The validity of the proposed model is demonstrated by comparing model predictions with measurements obtained using a two-dimensional cold model apparatus under different gas and/or liquid flow conditions.

Similar content being viewed by others

Abbreviations

- A i-l :

-

effective contact areas between phase i(i=g, s) and liquid phase in the unit volume of bed (m2/m3(bed))

- A M ij :

-

coefficient matrix to determine liquid flow region at the Mth iteration (—)

- C DG , C DS :

-

gas and bed drag force coefficients, respectively (—)

- C pm :

-

modified capillary number (—)

- d p :

-

diameter of packed particle (m)

- f(U s ):

-

probability frequency distribution of stochastic velocity (s/m)

- f(θ):

-

probability frequency distribution of liquid flow, defined by Eq. [21] (1/rad)

- F i j :

-

interaction force of phase i on phase j(i, j=g, l, or s) (N/m3)

- F i,j :

-

liquid flow rate flowing out of point (i, j) (cm2/min)

- F N ij :

-

liquid flow rate matrix at the Nth iteration (cm3/min)

- F i,j,n :

-

liquid flow rate flowing from point (i, j) into its surrounding region n(n=1, 2, ..., 8) (cm3/min)

- Ga m :

-

modified Gallileo number (—)

- G N ij :

-

dimensionless mass velocity matrix of gas flow at the Nth iteration (—)

- g :

-

gravity (m/s2)

- h t , h s , h d :

-

total, static, and dynamic holdup of liquid, respectively (—)

- P, P l :

-

pressures of gas and liquid phases, respectively (Pa)

- P Kij :

-

dimensionless gas pressure matrix at the Kth iteration (—)

- P i,j,n :

-

proportions of liquid flowing from point (i,j) into its surrounding region n (n=1, 2, ..., 8) (pct)

- Q g :

-

gas flow rate at gas inlet (Nm3/h)

- Q l :

-

liquid flow rate at liquid inlet (cm2/min)

- Re m :

-

modified Reynolds number (—)

- U g , U l :

-

velocity vectors of gas and liquid, respectively (m/s)

- U s :

-

stochastic velocity of liquid dispersion flow (m/s)

- U so :

-

maximum stochastic velocity of liquid dispersion flow (m/s)

- α :

-

liquid dispersion angle defined by Eq. [10] (rad)

- β :

-

liquid flow direction determined by U l at point (i,j) (rad)

- ε, ε l :

-

volume fractions of void space and liquid in a packed bed, respectively (—)

- ε o :

-

precision allowed in computation (—)

- θ n :

-

angles corresponding to the flow regions given in Fig. 4 (n=1, 2, ..., 8) (rad)

- θ l :

-

contact angle of liquid on the solid surface (rad)

- μ g , μ l :

-

viscosities of gas and liquid phases, respectively (Pa·s)

- ρ g , ρ l :

-

densities of gas and liquid, respectively (kg/m3)

- σ l :

-

surface tension of liquid (N/m)

- ψ :

-

shape factor of packed particle (—)

- ϕ :

-

dimensionless stream function (—)

- ϕ 1, ϕ 2 :

-

model parameters defined by Eqs. [6] and [7], respectively (m−1)

References

J. Yagi: Iron Steel Inst. Jpn. Int., 1993, vol. 33, pp. 619–39.

J. Szekely and Y. Kajiwara: Trans. Iron Steel Inst. Jpn., 1979, vol. 19, pp. 76–84.

Y. Kajiwara and J. Szekely: Metall. Trans. B, 1979, vol. 10, pp. 447–50.

G.X. Wang and Y.Z. Li: Iron and Steel (China), 1987, vol. 24, pp. 3–11.

T. Sugiyama, A. Nakagawa, H. Shibaike, and S. Oda: Tetsu-to-Hagané, 1987, vol. 73, pp. 2044–51.

G.S. Gupta, J.D. Litster, V.R. Rudolph, and E.T. White: Proc. 6th AusIMM Extractive Metallurgy Conf., Brisbane, Queensland, Australia. Australasian Institute of Mining and Metallurgy, Melbourne, 1994, pp. 295–301.

J. Wang, R. Kakahashi, and J. Yagi: Tetsu-to-Hagané, 1992, vol. 78, pp. 1124–31.

Y. Ohno and M. Schneider: Tetsu-to-Hagané, 1988, vol. 74, pp. 1923–30.

J. Wang, R. Kakahashi, and J. Yagi: Tetsu-to-Hagané, 1991, vol. 77, pp. 1585–92.

Y. Eto, K. Takeda, S. Miyagawa, S. Taguchi, and H. Itaya: Iron Steel Inst. Jpn. Int., 1993, vol. 3, pp. 681–86.

S.J. Chew: Cold Liquid Flow Modelling for the Blast Furnace Cohesion Zone, Internal Research Report, University of New South Wales, Sydney, New South Wales, Australia, 1994.

G.S. Gupta, J.D. Litster, V.R. Rudolph, and E.T. White: Liquid Distribution in the Bottom of a Blast Furnace, Final Report to BHP Research, University of Queensland, Queensland, Australia, 1993.

J. Bridgwater and N.D. Ingram: Trans. IChemE, 1971, vol. 49, pp. 163–69.

D.R. Gaskell: An Introduction to Transport Phenomena in Materials Engineering, Macmillan Publishing Company, New York, NY, 1992, pp. 160–75.

R.M. Bethea, B.S. Bethea, and T.L.B. Duran: Statistical Methods for Engineers and Scientists, Marcel Dekker, New York, NY, 1975, pp. 30–75.

T. Fukutake and V. Rajakumar: Trans. Iron Steel Inst. Jpn., 1982, vol. 22, pp. 355–64.

The Iron and Steel Institute of Japan: Blast Furnace Phenomena and Modelling, Elsevier Applied Science, Essex, England, 1987, pp. 377–82.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, G.X., Chew, S.J., Yu, A.B. et al. Modeling the discontinuous liquid flow in a blast furnace. Metall Mater Trans B 28, 333–343 (1997). https://doi.org/10.1007/s11663-997-0099-y

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-997-0099-y