Abstract

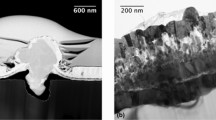

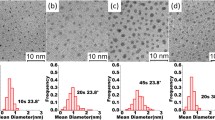

We investigate use of tantalum silicide (TaSi2, 400 nm)/platinum (Pt, 200 nm)/iridium (Ir, 200 nm)/platinum (Pt, 200 nm) as both a bond metal and a diffusion barrier to prevent oxygen (from air) and gold (from the wire bond) from infiltrating silicon carbide (SiC) monolithically integrated circuits operating above 500°C for over 1000 h in air. The TaSi2/Pt/Ir/Pt metallization is easily bonded for electrical connection to off-chip circuitry and does not require extra anneals or masking steps. It can be used directly on ohmic contact metals, dielectric insulating layers, or interconnect metal, because it adheres to silicon dioxide (SiO2), silicon nitride (Si3N4), and titanium (Ti). In this study, we investigate use of the new metallization of TaSi2/Pt/Ir/Pt (in deposition order) with TaSi2 resting on top of a Ti-SiC contact annealed at 600°C for 30 min in nitrogen, which allows the TaSi2 layer to react with the bottom platinum layer to form the Pt2Si diffusion barrier at the Pt-Ir interface. Since the iridium layer does not readily form a silicide, it prevents the silicon from migrating into the topmost platinum layer during further annealing or high-temperature integrated circuit operation. This leaves a pure platinum layer at the surface, ideal for gold wire bonding. We discuss the characteristics of the TaSi2/Pt/Ir/Pt metallization at 500°C after 10 h, 100 h, and 1000 h in air ambient and N2 ambient. Auger electron spectroscopy (AES) depth profiles of the metallization and field-emission scanning electron microscopy-focused ion beam (FESEM-FIB) cross-sections are also discussed.

Similar content being viewed by others

References

P.G. Neudeck, S.L. Garverick, D.J. Spry, L.-Y. Chen, G.M. Beheim, M.J. Krasowski, and M. Mehregany, Phys. Status Solidi A 206, 2329 (2009).

P.L. Dreike, D.M. Fleetwood, D.B. King, D.C. Sprauer, and T.E. Zipperian, IEEE Trans. Compon. Packag. Manuf. Technol. A 17, 594 (1994).

F.P. McCluskey, R. Grzybowski, and T. Podlesak, High Temperature Electronics (New York: CRC, 1997).

P.G. Neudeck, R.S. Okojie, and L.-Y. Chen, Proc. IEEE 90, 1065 (2002).

P.G. Neudeck, L.-Y. Chen, M.J. Krasowski, and N.F. Prokop, Materials Science Forum. Silicon Carbide and Related Materials 2009, Vol. 645–648 (Switzerland: Trans Tech Publications, 2010), p. 1135.

R.S. Okojie, D. Lukco, Y.L. Chen, and D.J. Spry, J. Appl. Phys. 91, 6553 (2002).

D. Spry, P. Neudeck, R. Okojie, L. Y. Chen, G. Beheim, R. Meredith, W. Mueller, and T. Ferrier, IMAPS International High Temperature Electronics Conference, May 18–20 (2004).

L.Y. Chen, D.J. Spry, and P.G. Neudeck, IMAPS International High Temperature Electronics Conference, May 15–18 (2006), p. 240.

R.S. Okojie, G.M. Beheim, G.J.Saad, and E. Savrun, AIAA Paper No. 2001-4652.

G.W. Hunter, J.C. Xu, L.K. Dungan, B.J. Ward, S. Rowe, J. Williams, D.B. Makel, C.C. Liu, and C.W. Chang, ECS Trans. 16, 333 (2008).

R.S. Okojie, D. Spry, J. Krotine, C. Salupo, and D.R. Wheeler, Materials Research Society Symposia Proceedings, Vol. 622 (Warrandale, PA: Materials Research Society, 2000).

http://www.cree.com/. Accessed 1 July 2010

D. Lukco, R.S. Okojie, and C.A. Blaha, Presented at 32nd Applied Surface Analysis Symposium (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Spry, D., Lukco, D. A Bondable Metallization Stack That Prevents Diffusion of Oxygen and Gold into Monolithically Integrated Circuits Operating Above 500°C. J. Electron. Mater. 41, 915–920 (2012). https://doi.org/10.1007/s11664-011-1792-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-011-1792-9