Abstract

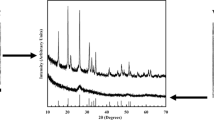

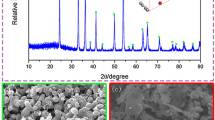

Thermochromic VO2 nanopowders were synthesized via the sol–gel method through mixing oxalic acid and vanadium pentoxide in ethanol. We investigated the effect of oxalic acid to vanadium pentoxide ratio on the formation of final product and found that excessive oxalic acid reduced the final product from VO2 to V2O3. Because decreasing the oxalic acid to vanadium pentoxide ratio is a time-consuming process, oxygen was introduced by using a low-porosity alumina tube. The heat treatment was performed inside an electrical tube furnace and in a variety of atmospheres, including pure nitrogen (99.999% purity) and nitrogen containing 5 vol.%, 10 vol.%, and 15 vol.% hydrogen. According to x-ray diffraction (XRD) results, the appropriate atmosphere for synthesizing VO2 nanopowder was the one which contained 10 vol.% hydrogen. In order to decrease the transition temperature in VO2 from 63.5°C to room temperature, W6+ doping was done by adding different amounts of tungstic acid sol to vanadium sol precursor. Differential scanning calorimetry (DSC) results showed that W6+ reduced the transition temperature of VO2 approximately 23°C/wt.%. Lattice straining estimated from XRD results confirmed that VO2 was doped. XRD results at 25°C and 100°C along with DSC results indicated that VO2 was transformed from a low-temperature monoclinic phase to a high-temperature rutile one along this temperature interval.

Similar content being viewed by others

References

L. Zhao, L. Miao, S. Tanemura, J. Zhou, L. Chen, X. Xiao, and G. Xu, Thin Solid Films 543, 157 (2013).

C. Sella, M. Maaza, O. Nemraoui, J. Lafait, N. Renard, and Y. Sampeur, Surf. Coat. Technol. 98, 1477 (1998).

C. Bianchi, L.M. Ferreira, J. Loureiro, A. Rodrigues, P. Duarte, A.C. Baptista, and I.M. Ferreira, J. Electron. Mater. 45, 1987 (2016).

A. Ozcelik, O. Cabarcos, D.L. Allara, and M.W. Horn, J. Electron. Mater. 42, 901 (2013).

J.H. Wang, S.E. Mohney, S.H. Wang, U. Chowdhury, and R.D. Dupuis, J. Electron. Mater. 33, 418 (2004).

L.Z. Shuyu Wang, S. Yu, M. Lu, and M. Liu, J. Electron. Mater. 46, 2153 (2017).

J. Ni, W. Jiang, K. Yu, Y. Gao, and Z. Zhu, Electrochim. Acta 56, 2122 (2011).

F.Y. Kong, M. Li, D.B. Li, Y. Xu, Y.X. Zhang, and G.H. Li, J. Cryst. Growth 346, 22 (2012).

F.J. Morin, Phys. Rev. Lett. 3, 34 (1959).

U. Schwingenschlögl and V. Eyert, Ann. Phys. 13, 475 (2004).

S. Li, G.A. Niklasson, and C.G. Granqvist, J. Appl. Phys. 108, 63525 (2010).

N.R. Mlyuka, G.A. Niklasson, and C.G. Granqvist, Appl. Phys. Lett. 95, 2 (2009).

Y. Gao, H. Luo, Z. Zhang, L. Kang, Z. Chen, J. Du, M. Kanehira, and C. Cao, Nano Energy 1, 221 (2012).

W. Burkhardt, T. Christmann, S. Franke, W. Kriegseis, D. Meister, B.K. Meyer, W. Niessner, D. Schalch, and A. Scharmann, Thin Solid Films 402, 226 (2002).

H. Liu, O. Vasquez, V.R. Santiago, L. Diaz, A.J. Rua, and F.E. Fernandez, J. Electron. Mater. 34, 491 (2005).

C.L. Xu, L. Ma, X. Liu, W.Y. Qiu, and Z.X. Su, Mater. Res. Bull. 39, 881 (2004).

M. Ghedira, H. Vincent, M. Marezio, and J.C. Launay, J. Solid State Chem. 22, 423 (1977).

F. Béteille and J. Livage, J. Sol Gel Sci. Technol. 921, 915 (1998).

G.R. Mutta, S.R. Popuri, M. Vasundhara, M. Maciejczyk, A.V. Racu, R. Banica, N. Robertson, J.I.B. Wilson, and N.S. Bennett, Mater. Res. Bull. 83, 135 (2016).

I. Mjejri, N. Etteyeb, and F. Sediri, Mater. Res. Bull. 60, 97 (2014).

J.-C. Valmalette and J.-R. Gavarri, Mater. Sci. Eng., B 54, 168 (1998).

L. Chen, C. Huang, G. Xu, L. Miao, J. Shi, J.H. Zhou, and X. Xiao, J. Nanomater. 8, 491051 (2012).

Z. Peng, W. Jiang, and H. Liu, J. Phys. Chem. C 111, 1119 (2007).

M.E.A. Warwick and R. Binions, J. Mater. Chem. A 2, 3275 (2014).

Z. Zhang, Y. Gao, H. Luo, L. Kang, Z. Chen, J. Du, M. Kanehira, Y. Zhang, and Z.L. Wang, Energy Environ. Sci. 4, 4290 (2011).

D.N. Sathyanarayana and C.C. Patel, J. Inorg. Nucl. Chem. 27, 297 (1965).

B. Pecquenard, S. Castro-Garcia, J. Livage, P.Y. Zavalij, M.S. Whittingham, and R. Thouvenot, Chem. Mater. 10, 1882 (1998).

C.Y. Kim, M. Lee, S.H. Huh, and E.K. Kim, J. Sol Gel Sci. Technol. 53, 176 (2010).

S. Ji, Y. Zhao, F. Zhang, and P. Jin, J. Cryst. Growth 312, 282 (2010).

I.L. Botto, M.B. Vassallo, E.J. Baran, and G. Minelli, Mater. Chem. Phys. 50, 267 (1997).

S.R. Popuri, M. Miclau, A. Artemenko, C. Labrugere, A. Villesuzanne, and M. Pollet, Inorg. Chem. 52, 4780 (2013).

N.H.D.A. Camargo, O.J. Bellini, E. Gemelli, and M. Tomiyama, Revista Matéria 12, 574 (2007).

R.M. Kettler, D.A. Palmer, and D.J. Wesolowski, J. Solut. Chem. 20, 905 (1991).

L. Zhao, L. Miao, C. Liu, C. Li, T. Asaka, Y. Kang, Y. Iwamoto, S. Tanemura, H. Gu, and H. Su, Sci. Rep. 4, 7000 (2014).

J. Zhang, H. He, Y. Xie, and B. Pan, J. Chem. Phys. 138, 114705 (2013).

W. Li, S. Ji, Y. Li, A. Huang, H. Luo, and P. Jin, RSC Adv. 4, 13026 (2014).

Z. Peng, Y. Wang, Y. Du, D. Lu, and D. Sun, J. Alloys Compd. 480, 537 (2009).

T. Nanba, S. Takano, I. Yasui, and T. Kudo, J. Solid State Chem. 90, 47 (1991).

J.-H. Cho, Y.-J. Byun, J.-H. Kim, Y.-J. Lee, Y.-H. Jeong, M.-P. Chun, J.-H. Paik, and T.H. Sung, Ceram. Int. 38, S589 (2012).

A.K. Zak, W.H.A. Majid, M.E. Abrishami, and R. Yousefi, Solid State Sci. 13, 251 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vostakola, M.F., Yekta, B.E. & Mirkazemi, S.M. The Effects of Vanadium Pentoxide to Oxalic Acid Ratio and Different Atmospheres on the Formation of VO2 Nanopowders Synthesized via Sol–Gel Method. J. Electron. Mater. 46, 6689–6697 (2017). https://doi.org/10.1007/s11664-017-5712-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5712-5