Abstract

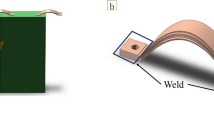

This study attempts to join copper (Cu) and aluminium (Al) sheets in micro-thickness by using friction stir welding. These materials are being used as current collectors in lithium-ion (li-ion) battery which are employed as power sources for electric vehicles. Several experiments have been carried out, followed by the measurement of electrical conductivity by using a 4-probe setup and electrochemical analysis by using a potentiodynamic polarization test and an electro impedance spectroscopy test in lithium phosphorus hexafluoride (LiPF6), an electrolytic medium. The welded samples have been found to achieve an electrical conductivity of 9% less than the base Cu and the corrosion resistance of the welded samples has been found to be increasing because of the formation of inter-metallic compounds such as Al4Cu9, AlCu4 and AlCu at the weld interface. Among them AlCu4 has the highest hardness and the recovery elastic modulus than the rest.

Similar content being viewed by others

References

A. Eftekhari, ACS Sustain. Chem. Eng. 7, 3684 (2018). https://doi.org/10.1021/acssuschemeng.7b04330.

C. Iclodean, B. Varga, N. Burnete, D. Cimerdean, and B. Jurchiş, IOP Conf. Ser. Mater. Sci. Eng. 252, 012058 (2017). https://doi.org/10.1088/1757-899x/252/1/012058.

S. Shawn Lee, T.H. Kim, S.J. Hu, W.W. Cai, and J.A. Abell, in MSEC2010-34168 (2015). https://doi.org/10.1115/msec2010-34168.

P. Wolfram, N. Lutsey, ICCT (2016), pp. 1–23. https://doi.org/10.13140/rg.2.1.2045.3364.

H.K. Charles, Appl. Phys. Lab. 26, 402 (2005).

V.V. Silberschmidt, Advanced Materials Modelling for Structures. Advanced Structured Materials, ed. H. Altenbach and S. Kruch (Berlin: Springer, 2013), p. 307.. https://doi.org/10.1007/978-3-642-35167-9.

G.L.B. Matijasevic and L. Brandt, Electr. Eng. II, 17 (2009).

A. Das, L. Dezhi, W. David, and G. David, World Electr. Veh. J. 9, 1 (2018). https://doi.org/10.3390/wevj9020022.

D. Nagy and O. Krammer, Solder. Surf. Mt. Technol. (2017). https://doi.org/10.1108/SSMT-11-2016-0029.

M.J. Brand, E.I. Kolp, P. Berg, T. Bach, P. Schmidt, and A. Jossen, J. Energy Storage 12, 45 (2017). https://doi.org/10.1016/j.est.2017.03.019.

J. Hayashi and Y. Miyazawa, IJST-2013 IOP Conf Ser. Mater. Sci. Eng. (2014). https://doi.org/10.1088/1757-899x/61/1/012015.

P. Kah, R. Suoranta, and J. Martikainen, in Proceedings of 16th International Conference on Mechanika (2011). https://doi.org/10.13140/2.1.3298.1284.

J. Huang, X. He, Y. Guo, Z. Zhang, Y. Shi, and D. Fan, J. Manuf. Process. 25, 16 (2017). https://doi.org/10.1016/j.jmapro.2016.10.003.

S. Ukita, K. Kokubo, T. Masuko, and T. Irie, Weld. Int. 17, 541 (2003). https://doi.org/10.1533/wint.2003.3143.

R. Borrisutthekul, P. Mitsomwang, S. Rattanachan, and Y.M. Mutoh, Energy Res J 1, 82 (2010).

G. Chryssolouris, Mech. Eng. Ser (2003). https://doi.org/10.1007/978-1-4757-4084-4.

I. Mys and M. Schmidt, Proc. SPIE 6107, 610703 (2006). https://doi.org/10.1117/12.648376.

T. Solchenbach, P. Plapper, and W. Cai, J. Manuf. Process. 16, 183 (2014). https://doi.org/10.1016/j.jmapro.2013.12.002.

W. Thomas and E. Nicholas, Mater. Des. 18, 269 (1997). https://doi.org/10.1016/S0261-3069(97)00062-9.

D. Mishra, S.K. Sahu, R.P. Mahto, S.K. Pal, and K. Pal, Lect. Notes Multidiscip. Ind. Eng. (2019). https://doi.org/10.1007/978-981-13-0378-4_6.

M.P. Iqbal, R. Jain, and S.K. Pal, J. Mater. Process. Technol. 274, 116258 (2019). https://doi.org/10.1016/j.jmatprotec.2019.116258.

D. Mishra, R.B. Roy, S. Dutta, S.K. Pal, and D. Chakravarty, J. Manuf. Process. 36, 373 (2018). https://doi.org/10.1016/j.jmapro.2018.10.016.

R.P. Mahto, R. Kumar, S.K. Pal, and S.K. Panda, J. Manuf. Process. 31, 624 (2018). https://doi.org/10.1016/j.jmapro.2017.12.017.

R.P. Mahto, C. Gupta, M. Kinjawadekar, A. Meena, and S.K. Pal, J. Manuf. Process. 38, 370 (2019). https://doi.org/10.1016/j.jmapro.2019.01.028.

K.P. Mehta and V.J. Badheka, Mater. Manuf. Process. 31, 233 (2016). https://doi.org/10.1080/10426914.2015.1025971.

O. Mypati, A. Sadhu, S. Sahu, and D. Mishra, J. Eng. Manuf. (2019). https://doi.org/10.1177/0954405419838379.

R.P. Mahto, R. Bhoje, S.K. Pal, H.S. Joshi, and S. Das, Mater. Sci. Eng. A 652, 136 (2016). https://doi.org/10.1016/j.msea.2015.11.064.

R.P. Mahto and S.K. Pal, in MSEC, vol 1 (2018).

R. Beygi, M. Kazeminezhad, and A.H. Kokabi, Trans. Nonferrous Metals Soc. China 22, 2925 (2012). https://doi.org/10.1016/s1003-6326(11)61555-0.

A. Elrefaey, M. Takahashi, and K. Ikeuchi, J. High Temp. Soc. 30, 286 (2004).

I. Galvão, J. Oliveira, A. Loureiro, and D. Rodrigues, Sci. Technol. Weld. Join. 16, 681 (2011). https://doi.org/10.1179/1362171811Y.0000000057.

I. Galvão, C. Leitão, A. Loureiro, and D.M. Rodrigues, Mater. Des. 42, 259 (2012). https://doi.org/10.1016/j.matdes.2012.05.058.

A. Elrefaey, M. Takahashi, and K. Ikeuchi, Weld. World 49, 93 (2005). https://doi.org/10.1007/BF03266481.

I. Galvão, D. Verdera, D. Gesto, A. Loureiro, and D.M. Rodrigues, J. Mater. Process. Technol. 213, 1920 (2013). https://doi.org/10.1016/j.jmatprotec.2013.05.004.

P. Kah, C. Vimalraj, J. Martikainen, and R. Suoranta, Int. J. Mech. Mater. Eng. (2015). https://doi.org/10.1186/s40712-015-0037-8.

S. Sattari, H. Bisadi, and M. Sajed, Int. J. Mech. Appl. 2, 1 (2012). https://doi.org/10.5923/j.mechanics.20120201.01.

S. Ahmed, A. Shubhrant, A. Deep, P. Saha, in AIMTDR (2014), pp. 1–5.

D. Kim, J.H. Chang, J. Park, and J.J. Pak, J. Mater. Sci. Mater. Electron. 22, 703 (2011). https://doi.org/10.1007/s10854-011-0357-2.

M. Elsa, A. Khorram, O.O. Ojo, and M. Paidar, Acad. Proc. Eng. Sci. (2019). https://doi.org/10.1007/s12046-019-1103-3.

K. Hiroshi and O. Seiichi, Trans. JIM 11, 431 (1970).

M.J.M. Hermans and M.H. Biglari, The ELFNET Book on Failure Mechanisms, Testing Methods, and Quality Issues of Lead-Free Solder Interconnects (Berlin: Springer, 2011)https://doi.org/10.1007/978-0-85729-236-0.

L. Valdes, Proc. I-R-E 29, 1429 (1952).

Y. Singh, Int. J. Mod. Phys. Conf. Ser. 22, 745 (2013). https://doi.org/10.1142/S2010194513010970.

N. Bowler and Y. Huang, Meas. Sci. Technol. (2005). https://doi.org/10.1088/0957-0233/16/11/009.

M.F. Goes, M.A. Sinhoreti, S. Consani, and M.A. Silva, Braz. Dent. J. IOP Conf. Ser. Mater. Sci. Eng. 9, 3 (1998). https://doi.org/10.1088/1742-6596/755/1/011001.

O. Mypati, S.K. Pal, and P. Srirangam, TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings (Berlin: Springer, 2019)https://doi.org/10.1007/978-3-030-05861-6.

H. Abe, Hitachi chemical technical report, 54, 31.

S. Dai, J. Chen, Y. Ren, Z. Liu, and J. Chen, Int. J. Electrochem. Sci. 12, 10589 (2017). https://doi.org/10.20964/2017.11.28.

X. Zhang, B. Winget, M. Doeff, J.W. Evans, and T.M. Devine, J. Electrochem. Soc. (2005). https://doi.org/10.1149/1.2041867.

R.P. Mahto, S. Anishetty, A. Sarkar, O. Mypati, S.K. Pal, and J.D. Majumdar, Mater. Metals Mater. Int. (2018). https://doi.org/10.1007/s12540-018-00222-x.

R. Drevet, O. Aaboubi, and H. Benhayoune, J. Solid State Electrochem. (2012). https://doi.org/10.1007/s10008-012-1742-3.

R. Chakraborty, V.S. Seesala, S. Sengupta, S. Dhara, P. Saha, and K. Das, Surf. Interfaces 10, 1 (2018). https://doi.org/10.1016/j.surfin.2017.11.002.

S.V. Hainsworth, H. Chandler, and T. Page, J. Mater. Res. 11, 1987 (1996).

S. Weng, Y. Huang, F. Xuan, and L. Luo, Proc. Eng. 130, 1761 (2015). https://doi.org/10.1016/j.proeng.2015.12.325.

Acknowledgments

The authors are grateful to Hall Effect Lab of the Physics Department and EPP lab of the Mechanical Engineering Department at IIT Kharagpur for providing the facilities to carry out the post-weld studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mypati, O., Mishra, D., Sahu, S. et al. A Study on Electrical and Electrochemical Characteristics of Friction Stir Welded Lithium-Ion Battery Tabs for Electric Vehicles. J. Electron. Mater. 49, 72–87 (2020). https://doi.org/10.1007/s11664-019-07711-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07711-8