Abstract

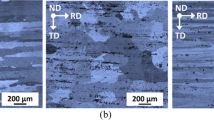

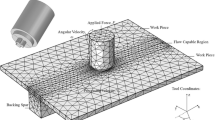

The material flow and microstructural evolution in the friction stir welds of a 6061-Al alloy to itself and of a 6061-Al alloy to 2024-Al alloy plates of 12.7 mm in thickness were studied under different welding conditions. The results showed that plastic deformation, flow, and mechanical mixing of the material exhibit distinct asymmetry characteristics at both sides of the same and dissimilar welds. The microstructure in dissimilar 6061-Al/2024-Al welds is significantly different from that in the welds of a 6061-Al alloy to itself. Vortex-like structures featured by the concentric flow lines for a weld of 6061-Al alloy to itself, and alternative lamellae with different alloy constituents for a weld of 6061-Al to 2024-Al alloy, are attributed to the stirring action of the threaded tool, in situ extrusion, and traverse motion along the welding direction. The mutual mixing in the dissimilar metal welds is intimate and far from complete. However, the bonding between the two Al-alloys is clearly complete. Three different regions in the nugget zone of dissimilar 6061-Al/2024-Al welds are classified by the mechanically mixed region (MMR) characterized by the relatively dispersed particles of different alloy constituents, the stirring-induced plastic flow region (SPFR) consisting of alternative vortex-like lamellae of the two Al-alloys, and the unmixed region (UMR) consisting of fine equiaxed grains of the 6061-Al alloy. Within all of these three regions, the material is able to withstand a very high degree of plastic deformation due to the presence of dynamic recovery or recrystallization of the microstructure. The degree of material mixing, the thickness of the deformed Al-alloy lamellae, and the material flow patterns depend on the related positions in the nugget zone and the processing parameters. Distinct fluctuations of hardness are found to correspond to the microstructural changes throughout the nugget zone of dissimilar welds.

Similar content being viewed by others

References

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Templesmith, and C.J. Dawes: “Friction Stir Welding Butt Welding,” G.B. Patent Application No. 9125978.8, Dec. 1991; U.S. Patent No. 5460317, Oct. 1995.

K. Colligan: “Material Flow Behavior during Friction Stir Welding of Aluminum,” Weld. J., 75(7), 1999, pp. 229s-37s.

H. Larsson, L. Karlsson, S. Stoltz, and E.L. Bergqvist: “Joining of Dissimilar Al-alloys by Friction Stir Welding,” 2nd International Symposium on Friction Stir Welding, 26–28 June 2000.

T. Hashimoto, N. Nishikawa, S. Tazaki, and M. Enomoto: “Mechanical Properties of Joints for Aluminum Alloys with Friction Stir Welding Process,” in Proc. Conf. INALCO’98, 7th International Conference Joints in Aluminum, April 1998, TWI.

F. Palm: “Charakterisierung des Materialflusses beim Reibruehrschweissen (Friction Stir Welding) von Al-Werkstoffen,” in Proc. GKSS/TWI Workshop on “Friction Stir Welding”, May 1999, pp. 23–29.

P. Threadgill: “Friction Stir Welds in Aluminum Alloys—Preliminary Microstructural Assessment,” TWI Bulletin, 1997, 38(2), pp. 30–33.

C.G. Rhodes, M.W. Mahoney, and W.H. Bingel: “Effects of Friction Stir Welding on Microstructure of 7075 Aluminum,” Scr. Mater., 1997, 36(1), pp. 69–75.

E.D. Nicholas and S.W. Kallee: “Friction Stir Welding—A Decade On,” IIW Asian Pacific International Congress, Sydney, 29 October to 2 November 2000, pp. 1–12.

W.M. Thomas: “Friction Stir Welding of Ferrous Materials—a Feasibility Study,” 1st International Symposium on Friction Stir Welding, 14–16 June 1999.

L.E. Murr, G. Liu, and J.C. McClure: “A TEM Study of Precipitation and Related Microstructures in Friction-Stir-Welded 6061 Aluminum,” J. Mater. Sci., 1998, 33, pp. 1243–51.

A.P. Reynolds, W.D. Lockwood, and T.U. Seidel: “Processing-Property Correlation in Friction Stir Welds,” Mater. Sci. Forum, 2000, 331–337, pp. 1719–24.

P. Colegrove: 3-Dimensional Flow and Thermal Modeling of the Friction Stir Welding Process, 2nd International Symposium on Friction Stir Welding, 26–28 June 2000.

C.B. Smith, G.J. Bendzsak, T.H. North, J.H. Hinrichs, J.S. Noruk, and R.J. Heideman: “Heat and Material Flow Modeling of the Friction Stir Welding Process,” 2nd International Symposium on Friction Stir Welding, 26–28 June 2000.

Y. Li, L.E. Murr, and J.C. McClure: “Solid-State Flow Visualization in the Friction-Stir Welding of 2024 Al to 6061 Al,” Scr. Mater., 1999, 40(9), pp. 1041–46.

L.E. Murr, Y. Li, E.A. Trillo, R.D. Flores, and J.C. McClure: “Microstructures in Friction-Stir Welded Metals,” J. Mater. Process. Manuf. Sci., 1998, 7(10), pp. 145–61.

L.E. Murr, Y. Li, R.D. Flores, E.A. Trillo, and J.C. McClure: “Intercalation Vortices and Related Microstructural Features in the Friction-Stir-Welding of Dissimilar Metals,” Mater. Res. Innovat. 1998, 2, pp. 150–63.

Y. Li, E.A. Trillo, and L.E. Murr: Friction-Stir Welding of Aluminum Alloy 2024 to Silver, J. Mater. Sci. Lett., 2000, 19, pp. 1047–51.

L.E. Murr, R.D. Flores, O.V. Flores, J.C. McClure, G. Liu, and D. Brown: “Friction-Stir Welding: Microstructural Characterization,” Mater. Res. Innovat., 1998, 1, pp. 211–23.

L.E. Murr, Ying Li, E.A. Trillo, and J.C. McClure: “Fundamental Issues and Industrial Applications of Friction-Stir Welding,” Mater. Technol., 2000, 15(1), pp. 37–48.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ouyang, J.H., Kovacevic, R. Material flow and microstructure in the friction stir butt welds of the same and dissimilar aluminum alloys. J. of Materi Eng and Perform 11, 51–63 (2002). https://doi.org/10.1007/s11665-002-0008-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-002-0008-0