Abstract

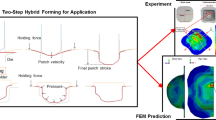

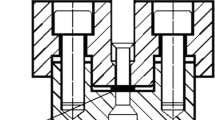

In this paper, the superplastic forming (SPF) potential of two fine-grained 5083 aluminum alloys were studied under various stress states with the use of both high temperature tensile testing and pneumatic bulge testing. Experiments with the pneumatic bulge test were performed at temperatures ranging from 475 to 525 °C under three different strain paths ranging from equi-biaxial to approaching plane strain. The effects of temperature on total elongation, m-value, final thickness distribution, dome height, and cavitation were investigated for the case of uniaxial and equi-biaxial stretching. Increased temperature in bulge forming was found to improve the thickness distribution in the formed parts, but did not have a significant effect on dome height. The shape of the forming limit diagram (FLD) was found to be significantly different than that of FLDs commonly used in room temperature stamping. Results indicate that determination of forming limits in SPF cannot be represented with a simple FLD and additional metrics such as external thinning and internal cavitation need to be considered to determine a material’s SPF potential.

Similar content being viewed by others

References

C.H. Hamilton, A.K. Ghosh, Superplastic Sheet Forming, Metals Handbook, ASM, 1988, p 852–869

X.D. Ding, H.M. Zbib, C.H. Hamilton, A.E. Bayoumi 1997 On the Stability of Biaxial Stretching with Application to the Optimization of Superplastic Blow-Forming. J. Eng. Mater. Technol. 119:26–31

Z. Marciniak, K. Kucznski 1967 Limit Strains in the Processes of Stretch-Forming Sheet Metal. Intl. J. Mech. Sci. 9:609–620

K.C. Chan, K.K. Chow 2002 Analysis of Hot Limit Strains of a Superplastic 5083 Aluminum Alloy Under Biaxial Tension. Intl. J. Mech. Sci. 44:1467–1478

M. Vulcan, K. Siegert, Forming Limited Diagram of a Superplastic Formable AA5083 Aluminum Alloy. Advances in Superplasticity and Superplastic Forming, Proc. TMS Conf., E.M. Taleff, P.A. Friedman, P.E. Krajewski, R.S. Mishra, and J.G. Schroth, Eds., 2004, p 351–360

R. Verma, P.A. Friedman, A.K. Ghosh, S. Kim, C. Kim 1996 Characterization of Superplastic Deformation Behavior of a Fine Grain 5083 Al Alloy Sheet. Metal. Trans. Mater. Ser. A 27:1889–1898

H. Iwasaki, H. Hosokawa, T. Mori, T. Tagata, K. Higashi 1998 Quantitative Assessment of Superplastic Deformation Behavior in a Commercial 5083 Alloy. Mater. Sci. Eng. A 252:199–202

K. Kanna, C.H. Johnson, C.H. Hamilton 1998 A Study of Superplasticity in a Modified 5083 AL-Mg-Mn alloy. Metal. Trans. Mater. Ser. A 29:1211–1120

S.N. Patankar, T.M. Jen 1998 Inhomogeneities in Initial Cavity Distribution in a Superplastic Al5083 Alloy. Scripta Mater. 38(8):1255–1261

P.A. Friedman, A.K. Ghosh 1996 Microstructural Evolution and Superplastic Deformation Behaviour of Fine Grain 5083Al. Metal. Trans. Mater. Ser. A 27:3827–3839

X.G. Jiang, J.C. Earthman, F.A. Mohamed 1994 Cavitation and Cavity-induced Fracture During Superplastic Deformation. J. Mater. Sci. 29:5499–5506

E.M. Taleff, D.R. Lesuer, J. Wadsworth 1996 Enhanced Ductility in Coarse-grained Al-Mg Alloys. Metal. Mater. Trans. A 27A:343–352

K.C. Chan, G.Q. Tong 1998 The Cavitation Behavior of a High-strain-rate Superplastic Al6061/20SiCw Composite Under Uniaxial and Equibiaxial Tension. Scripta Mater. 38:1705–1710

C.C. Bampton, The Effect of Superplastic Deformation on Subsequent Service Properties of Fine Grained 7475Al. J. Eng. Mater. Technol., 1983, 105, p 55–60

J. Pilling, N. Ridley 1986 Effect of Hydrostatic Pressure on Cavitation in Superplastic Aluminium Alloys. Acta Mater. 34:669–679

K.K. Chow, K.C. Chan 2001 The Cavitation Behavior of a Coarse-grained Al5052 Alloy Under Hot Uniaxial and Equibiaxial Tension. Mater. Lett. 49:189–196

Z.X. Guo, N. Ridley 1989 Modeling of Super Plastic Bulge Forming of Domes. Mater. Sci. Eng. A 121:97–104

D.H. Bae, A.K. Ghosh 2002 Cavity Formation and Early Growth in a Superplastic Al-Mg Alloy. Acta Mater. 50:511–523

D.H. Bae, A.K. Ghosh 2002 Cavity Growth in a Superplastic Al-Mg Alloy: I. Experimental Study. Acta Mater. 50:993–1009

D.H. Bae, A.K. Ghosh, J.R. Bradley 2003 Stress-State Dependence of Cavitation and Flow Behavior in Superplastic Aluminum Alloys. Metal. Mater. Trans. 34A:2449–2463

H. Imamur, and N. Ridley, Superplastic Behaviour in a Commercial 5083 Aluminium Alloy, Proc. Intl Conf. in Superplasticity of Advanced Materials, ICSAM’91, Osaka, Japan, S. Hori, M. Tokizane, and N. Furushiro, Eds., 1991, p 453–458

J.S. Vetrano, C.A. Lavender, C.H. Hamilton, M.T. Smith, S.M. Bruemmer 1994 Superplastic Behaviour in a Commercial 5083 Aluminium Alloy. Scripta Metal. Mater. 30(3):565–570

W.B. Lievers, A.K. Pilkey, D.J. Lioyd 2003 The Influence of Iron Content on the Bendability of AA6111 Sheet. Mater. Sci. Eng. A 361:312–320

P.A. Friedman, W.B. Copple 2004 Superplastic Response in Al-Mg Sheet Alloys. J. Mater. Eng. Perform. 13:335–347

S.P. Keeler 1965 Determination of Forming Limits in Automotive Stampings. Sheet Mental Industry 42:683–691

R.M. Cleveland, A.K. Ghosh, J.R. Bradley 2003 Comparison of Superplastic Behavior in Two 5083 Aluminum Alloys. Mater. Sci. Eng. A 351:228–236

Author information

Authors and Affiliations

Corresponding author

Additional information

This article was presented at Materials Science & Technology 2006, Innovations in Metal Forming symposium held in Cincinnati, OH, October 15-19, 2006.

Rights and permissions

About this article

Cite this article

Luo, Y., Miller, C., Luckey, G. et al. On Practical Forming Limits in Superplastic Forming of Aluminum Sheet. J. of Materi Eng and Perform 16, 274–283 (2007). https://doi.org/10.1007/s11665-007-9048-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9048-9