Abstract

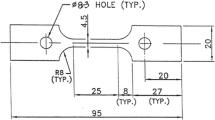

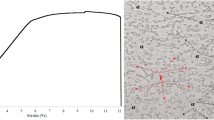

The purpose of the present work was to investigate the effect of oxide fluxes on weld morphology, arc voltage, mechanical properties, angular distortion and hot cracking susceptibility obtained with TIG welding, which applied to the welding of 5 mm thick austenitic stainless steel plates. A novel variant of the autogenous TIG welding process, oxide powders (Al2O3, Cr2O3, TiO2, SiO2 and CaO) was applied on a type 304 stainless steel through a thin layer of the flux to produce a bead on plate welds. The experimental results indicated that the increase in the penetration is significant with the use of Cr2O3, TiO2, and SiO2. A-TIG welding can increase the weld depth to bead-width ratio, and tends to reduce the angular distortion of the weldment. It was also found that A-TIG welding can increase the retained delta-ferrite content of stainless steel 304 welds and, in consequence, the hot-cracking susceptibility of as-welded is reduced. Physically constricting the plasma column and reducing the anode spot are the possible mechanism for the effect of certain flux on A-TIG penetration.

Similar content being viewed by others

References

Huang H.Y., Shyu S.W., Tseng K.H., Chou C.P. (2006) Effects of the Process Parameters on Austenitic Stainless Steel by TIG-flux Welding. J. Mater. Sci. Technol. 22(3):367-373

Howse D.S., Lucas W. (2000) Investigation into Arc Constriction by Active Fluxes for Tungsten Inert Gas Welding. Sci. Technol. Weld. Joining 5(3):189-193

Tanaka M., Shimizu T., Terasaki H., Ushio M., Koshi-ishi F., Yang C.-L. (2000) Effects of Activating Flux on Arc Phenomena in Gas Tungsten Arc Welding. Sci. Technol Weld. Joining 5(6):397-402

Kuo M., Sun Z., Pan D. (2001) Laser Welding with Activating Flux. Sci. Technol Weld. Joining 6(1):17-22

Paskell T., Lundin C., Castner H. (1997) GTAW Flux Increases Weld Joint Penetration. Weld. J. 76(4):57-62

Yang C.L., Lin S.B., Liu F.Y., Lin W., Zhang Q.T. (2003) Research on the Mechanism of Penetration Increase by Flux in A-TIG Welding. J. Mater. Sci. Technol. 19:225-227

Modenesi P.J., Apolinário E.R., Pereira I.M. (2000) TIG Welding with Single-component Fluxes. J. Mater. Process. Technol. 99(1):260-265

Huang H.Y., Shyu S.W., Tseng K.H., Chou C.P. (2005) Evaluation of TIG-Flux Welding on the Characteristics of Stainless Steel. Sci. Technol. Weld. Joining 10(5):566-573

H.Y. Huang, S.W. Shyu, K.H. Tseng, and C.P. Chou, Effect of A-TIG Welding on the Morphology of Stainless Steel Welds, Proceedings of 7th International Conference on Trends in Welding Research, ASM International, 2005

Ogawa T., Tsunetomi E. (1982) Hot Cracking Susceptibility of Austenitic Stainless Steel. Weld. J. 61(3):82-93

Brook J.A. (1974) Effect of Alloy Modifications on HAZ Cracking of A-286 Stainless Steel. Weld. J. 53(11):517-523

Lundin C.D., Turner P.W. (1970) Effect of the Hot Cracking of Uranium Weld Metal-Part I. Weld. J. 49(12):579-587

Tseng K.H., Chou C.P. (2001) Effect of Pulsed Gas Tungsten Arc Welding on Angular Distortion in Austenitic Stainless Steel Weldments. Sci. Technol. Weld. Joining 6(3):149-153

Tseng K.H., Chou C.P. (2002) The Effect of Pulsed GTA Welding on the Residual Stress of a Stainless Steel Weldment. J. Mater. Process. Technol. 123:346-353

Pavlovsky V.I., Masubuchi K. (1994) Research in the U.S.S.R. on Residual Stresses and Distortion in Welded Structures. Weld. Res. Counc. Bull. 338:44-48

Tseng K.H., Chou C.P. (2002) Effect of Nitrogen Addition to Shielding Gas on Residual Stress of Stainless Steel Weldments. Sci. Technol. Weld. Joining 7(1):57-62

Chen M.H., Chou C.P. (1999) Effect of Thermal Cycles on Ferrite Content of Austenitic Stainless Steel. Sci. Technol. Weld. Joining 4(1):58-62

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shyu, S.W., Huang, H.Y., Tseng, K.H. et al. Study of the Performance of Stainless Steel A-TIG Welds. J. of Materi Eng and Perform 17, 193–201 (2008). https://doi.org/10.1007/s11665-007-9139-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9139-7