Abstract

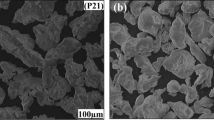

In the steel industry, nickel coating on copper has increased the lifespan of continuous ingot casting molds. The objective of this work is to estimate the porosity of nanocrystalline nickel electrodeposited onto copper. Characteristics of nickel coating such as hardness, wear resistance, porosity, morphology, and adhesion are very important for maximum performance of molds. The effective porosity in nickel coating was determined by using anodic voltammetry. The porosity of electrodeposited nickel onto copper increased from 0.16% up to 6.22% as the current density increased from 1.5 up to 8.0 A dm−2. The morphology of the nickel electrodeposited at lower current densities was more compact. Tribological properties were studied using hardness measurements, and calotest. Results of calotest indicated a wear coefficient of 10−6 for all samples. An extremely low friction coefficient of 0.06-0.08 was obtained for the sample deposited with a current density of 1.5 A dm−2, and a friction coefficient of 0.15-0.21 was measured for the nickel coating electrodeposited at a current density of 5 A dm−2. Effects of the current density of the electrodeposition process on the morphology, porosity, and tribological properties were evaluated.

Similar content being viewed by others

References

I.M. Hutchings, Tribology: Friction and wear of Engineering Materials, CRC Press, London, 1992

J.R. Tuck, A.M. Korsunsky, R.I. Davidson, S.J. Bull, D.M. Elliot, Modelling of the Hardness of Electroplated Nickel Coatings on Copper Substrates, Surf. Coat. Technol., 127 (1), 2000, p. 1–8

S. Rossi, F. Chini, G. Straffelini, P.L. Bonora, R. Moschini, A Stampali, Corrosion Protection Properties of Electroless Nickel/PTFE, Phosphate/MoS2 and Bronze/PTFE Coatings Applied to Improve the Wear Resistance of Carbon Steel, Surf. Coat. Technol., 173 (2–3), 2003, p.235–242

A.M. El-Sherik, J. Shirokoff, and U. Erb, Stress Measurements in Nanocrystalline Nickel, J. Alloy. Compd., 2005, 389, p.140

E. Rabinowicz, Friction and Wear of Materials, Wiley-Interscience, New York, 1995

K. Krishnaveni, T.S.N. Sankara Narayanan, S.K. Seshadri, Electrodeposited Ni-B Coatings: Formation and Evaluation of Hardness and Wear Resistance, Mater. Chem. Phys., 99 (2–3) 2006, p. 300–308

D.H. Jeong, F. Gonzalez, G. Palumbo, K.T. Aust, U. Erb, The Effect of Grain Size on the Wear Properties of Electrodeposited Nanocrystalline Nickel Coatings, Scripta Mater. 44(3), 2001, p. 493–499

R. Mishra, B. Basu, R. Balasubramaniam, Effect of Grain Size on the Tribological Behavior of Nanocrystalline Nickel, Mater. Sci. Eng. A, 373 (1–2), 2004, p. 370–373

L. Wang, Y. Gao, T. Xu, Q. Xue, A Comparative Study on the Tribological Behavior of Nanocrystalline Nickel and Cobalt Coatings Correlated with Grain Size and Phase Structure, Mat. Chem. Phys., 99(1), 2006, p. 96–103

H.A Ponte, A.C.T. Gomes, A.M. Maul, M.J.J.S. Ponte, Voltammetric Anodic Dissolution (VAD) Applied to the Quantitative Analysis of Coating Discontinuities—Influence of Electrodeposition Process Parameters, J. Appl. Electrochem. 34, 2004, p. 147–150

H.A Ponte, A.M. Maul, Porosity Determination of Nickel Coatings on Copper by Anodic Voltammetry, J. Appl. Electrochem. 32, 2002, p. 641–646

F. Lantelme, A Seghiouer, Model of Nickel Electrodeposition from Acidic Medium, J. Appl. Electrochem. 28 (9), 1998, p. 907–913

C.Q. Cui, J.Y. Lee, Nickel Deposition from Unbuffered Neutral Chloride Solutions in the Presence of Oxygen, Electrochim. Acta, 40(11), 1995, p. 1653–1662

L. Garcia, A Conde, G. Langelaan, J. Fransaer, J.P. Celis, Improved Corrosion Resistance Through Microstructural Modifications Induced by Codepositing SiC-Particles with Electrolytic Nickel, Corros. Sci., 45 (6), 2003, p. 1173–1189

S.M.L. Agostinho, Introdução à Engenharia Eletroquímica (Introduction to Electrochemistry Engineering), Ed. Associação Brasileira de Metalurgia e Materiais, São Paulo, 1990, Chap. 5, p 189

C. Fan, J.P. Celis, J.R. Roos, Relation Between Plating Overpotential and Porosity of Thin Nickel Electrolytic Coatings, J. Electrochem. Soc. 138 (10), 1991, p. 2917–2920

C.A Schuh, T.G. Nieh, T. Yamasaki, Hall-Petch Breakdown Manifested in Abrasive Wear Resistance of Nanocrystalline Nickel, Scripta Mater. 46 (10), 2002, p. 735–740

E. Rabinowicz, Friction and Wear of Materials, Oxford University Press, Park Ridge, 1984

Z.N. Farhat, Y. Ding, D.O. Northwood, A.T. Alpas, Effect of Grain Size on Friction and Wear of Nanocrystalline Aluminum, Mater. Sci. Eng. A, 206 (2), 1996, p. 302–313

J.E. Hines, R.C. Bradt, and J.V. Biggers, The Effect of Grain Size on the Wear Properties of Electrodeposited Nanocrystalline Nickel Coatings, Wear of Materials 1977, The International Conference on Wear of Materials, W.A. Glaeser et al., Eds., ASME, St Louis, 1977

K. Yamamoto, H. Ito, S. Kujime, Nano-Multilayered CrN/BCN Coating for Anti-Wear and Low Friction Applications, Surf. Coat. Technol. 201 (9–11), 2007, p. 5244–5248

Acknowledgment

The authors would like to thank FAPEMIG, Sponsor Agency of the State of Minas Gerais, Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lins, V., Cecconello, E.S. & Matencio, T. Effect of the Current Density on Morphology, Porosity, and Tribological Properties of Electrodeposited Nickel on Copper. J. of Materi Eng and Perform 17, 741–745 (2008). https://doi.org/10.1007/s11665-008-9205-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-008-9205-9