Abstract

The aim of this investigation was to evaluate the microstructural change after laser welding and its effect on the tensile properties and strain hardening behavior of DP600 and DP980 dual-phase steels. Laser welding led to the formation of martensite and significant hardness rise in the fusion zone because of the fast cooling, but the presence of a soft zone in the heat-affected zone was caused by partial vanishing and tempering of the pre-existing martensite. The extent of softening was much larger in the DP980-welded joints than in the DP600-welded joints. Despite the reduction in ductility, the ultimate tensile strength (UTS) remained almost unchanged, and the yield strength (YS) indeed increased stemming from the appearance of yield point phenomena after welding in the DP600 steel. The DP980-welded joints showed lower YS and UTS than the base metal owing to the appearance of severe soft zone. The YS, UTS, and strain hardening exponent increased slightly with increasing strain rate. While the base metals had multi-stage strain hardening, the welded joints showed only stage III hardening. All the welded joints failed in the soft zone, and the fracture surfaces exhibited characteristic dimple fracture.

Similar content being viewed by others

Notes

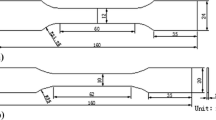

Bead-on-plate means a butt weld with full penetration on the blanks of uniform thickness.

References

S.R. Mediratta, V. Ramaswamy, V. Singh, and P. Rama Rao, Microstructure-Mechanical Property Correlations in Dual Phase Steels, Trans. Ind. Inst. Met., 1985, 38, p 350–372

M. Sarwar, E. Ahmad, N. Hussain, B. Ahmad, and T. Manzoor, Crack Path Morphology in Dual-Phase Steel, J. Mater. Eng. Perform., 2006, 15, p 352–354

M. Xia, E. Biro, Z. Tian, and Y.N. Zhou, Effects of Heat Input and Martensite on HAZ Softening in Laser Welding of Dual Phase Steels, ISIJ Int., 2008, 48, p 809–814

D.L. Chen, Z.G. Wang, X.X. Jiang, S.H. Al, and C.H. Shih, Dependence of Near-Threshold Fatigue Crack Growth on Microstructure and Environment in Dual-Phase Steels, Mater. Sci. Eng. A, 1989, 108, p 141–151

M. Sarwar and R. Priestner, Fatigue Crack Propagation Behavior in Dual-Phase Steel, J. Mater. Eng. Perform., 1999, 8, p 245–251

R.G. Davies, Influence of Silicon and Phosphorus on the Mechanical Properties of Both Ferrite and Dual-Phase Steels, Metall. Trans. A, 1979, 10, p 113–118

T.S. Byun and I.S. Kim, Tensile Properties and Inhomogeneous Deformation of Ferrite-Martensite Dual-Phase Steels, J. Mater. Sci., 1993, 28, p 2923–2932

N.D. Beynon, S. Oliver, T.B. Jones, and G. Fourlaris, Tensile and Work Hardening Properties of Low Carbon Dual Phase Strip Steels at High Strain Rates, Mater. Sci. Technol., 2005, 21, p 771–778

M. Sarwar and R. Priestner, Influence of Ferrite-Martensite Microstructural Morphology on Tensile Properties of Dual-Phase Steel, J. Mater. Sci., 1996, 31, p 2091–2095

H. Kumar, P. Ganesh, R. Kaul, B.T. Rao, P. Tiwari, R. Brajpuriya, S.M. Chaudhari, and A.K. Nath, Laser Welding of 3 mm Thick Laser-Cut AISI, 304 Stainless Steel Sheet, J. Mater. Eng. Perform., 2006, 15, p 23–31

S.K. Samanta, S.K. Mitra, and T.K. Pal, Microstructure and Oxidation Characteristics of Laser and GTAW Weldments in Austenitic Stainless Steels, J. Mater. Eng. Perform., 2008, 17, p 908–914

C. Maletta, A. Falvo, F. Furgiuele, G. Barbieri, and M. Brandizzi, Fracture Behaviour of Nickel-Titanium Laser Welded Joints, J. Mater. Eng. Perform., 2009, 18, p 569–574

M. Marya and G.R. Edwards, Factors Controlling the Magnesium Weld Morphology in Deep Penetration Welding by a CO2 Laser, J. Mater. Eng. Perform., 2001, 10, p 435–443

H. Tao, W. Tong, L.G. Hector, Jr., and P.D. Zavattieri, Uniaxial Tensile and Simple Shear Behavior of Resistance Spot-Welded Dual-Phase Steel Joints, J. Mater. Eng. Perform., 2008, 17, p 517–534

N. Sreenivasan, M. Xia, S. Lawson, and Y. Zhou, Effect of Laser Welding on Formability of DP980 Steel, J. Eng. Mater. Technol., 2008, 130, p 041004–041012

M. Xia, N. Sreenivasan, S. Lawson, Y. Zhou, and Z. Tian, A Comparative Study of Formability Of Diode Laser Welds in DP980 and HSLA Steels, J. Eng. Mater. Technol. Trans. ASME, 2007, 129, p 446–452

A. Bag, K.K. Ray, and E.S. Dwarakadasa, Influence of Martensite Content and Morphology on Tensile and Impact Properties of High-Martensite Dual-Phase Steels, Metall. Mater. Trans. A, 1999, 30, p 1193–1202

E. Ahmad, T. Manzoor, K.L. Ali, and J.I. Akhter, Effect of Microvoid Formation on the Tensile Properties of Dual-Phase Steel, J. Mater. Eng. Perform., 2000, 9, p 306–310

H. Chen and G. Cheng, Effect of Martensite Strength on the Tensile Strength of Dual Phase Steels, J. Mater. Sci., 1989, 24, p 1991–1994

D. Das and P.P. Chattopadhyay, Influence of Martensite Morphology on the Work-Hardening Behavior of High Strength Ferrite-Martensite Dual-Phase Steel, J. Mater. Sci., 2009, 44, p 2957–2965

M. Erdogan, The Effect of New Ferrite Content on the Tensile Fracture Behaviour of Dual Phase Steels, J. Mater. Sci., 2002, 37, p 3623–3630

M.R. Akbarpour and A. Ekrami, Effect of Temperature on Flow and Work Hardening Behavior of High Bainite Dual Phase (HBDP) Steels, Mater. Sci. Eng. A, 2008, 475, p 293–298

M.S. Nagorka, G. Krauss, and D.K. Matlock, Effect of Microstructure and Strain Rate on the Stage III, Strain Hardening and Ductility of Dual-Phase Steels, Mater. Sci. Eng., 1987, 94, p 183–193

F.H. Samuel, Effect of Strain Rate and Microstructure on the Work Hardening of a Cr-Mo-Si Steel, Mater. Sci. Eng., 1987, 92, p l5–l8

J.H. Hollomon, Tensile Deformation, Am. Inst. Min. Metall. Eng. Trans. Iron Steel Div, 1945, 162, p 268–289

B. Jaoul, Etude de Plasticite et Application oux Meatux, J. Mech. Phys. Solid., 1957, 5, p 95–114

C. Crussard, Relationship Between Exact Form of Tensile Curves of Metals and Accompanying Changes in Their Structure, Rev. Metall., 1953, 50, p 697–710

P. Ludwik, Elements of Technical Mechanics, Springer, Berlin, 1909

H.W. Swift, Plastic Instability Under Plane Stress, J. Mech. Phys. Solid., 1952, 1, p 1–18

S.N. Monteiro and R. Reed-Hill, On the double-n behaviour of iron, Metall. Mater. Trans. B, 1971, 2, p 2947–2948

L.F. Ramos, D.K. Matlock, and G. Krauss, On the Deformation Behavior of Dual-Phase Steels, Metall. Trans. A, 1979, 10, p 259–261

F.H. Samuel, Tensile Stress-Strain Analysis of Dual-Phase Structures in a Mn-Cr-Si Steel, Mater. Sci. Eng., 1987, 92, p l1–l4

B.K. Jha, R. Avtar, V. Sagar Dwivedi, and V. Ramaswamy, Applicability of Modified Crussard-Jaoul Analysis on the Deformation Behaviour of Dual-Phase Steels, J. Mater. Sci. Lett., 1987, 6, p 891–893

J. Lian, Z. Jiang, and J. Liu, Theoretical Model for the Tensile Work Hardening Behaviour of Dual-Phase Steel, Mater. Sci. Eng. A, 1991, 147, p 55–65

M.S. Xia, M.L. Kuntz, Z.L. Tian, and Y. Zhou, Failure Study on Laser Welds of Dual Phase Steel in Formability Testing, Sci. Technol. Weld. Join., 2008, 13, p 378–387

N. Farabi, D.L. Chen, J. Li, Y. Zhou, and S.J. Dong, Microstructure and Mechanical Properties of Laser Welded DP600 Steel Joints, Mater. Sci. Eng. A, 2010, 527, p 1215–1222

P. Movahed, S. Kolahgar, S.P.H. Marashi, M. Pouranvari, and N. Parvin, The Effect of Intercritical Heat Treatment Temperature on the Tensile Properties and Work Hardening Behavior of Ferrite-Martensite Dual Phase Steel Sheets, Mater. Sci. Eng. A, 2009, 518, p 1–6

G.E. Dieter, Yield Point Phenomenon, Mechanical Metallurgy, SI, Metric Edition, McGraw-Hill Book Co., London, 1988, p 197–201

W.D. Callister, Jr., Plastic Deformation, Material Science and Engineering—An Introduction, 7th ed., Wiley, New York, 2007, p 143–144

C.-Y. Kang, T.-K. Han, B.-K. Lee, and J.-K. Kim, Characteristics of Nd:YAG Laser Welded 600 MPa Grade TRIP and DP Steels, Mater. Sci. Forum, 2007, 539–543, p 3967–3972

M.P. Miles, J. Pew, T.W. Nelson, and M. Li, Comparison of Formability of Friction Stir Welded and Laser Welded Dual Phase 590 Steel Sheets, Sci. Technol. Weld. Join., 2006, 11, p 384–388

H. Huh, S. Kim, J. Song, and J. Lim, Dynamic Tensile Characteristics of TRIP-Type and DP-Type Steel Sheets for an Auto-Body, Int. J. Mech. Sci., 2008, 50, p 918–931

U.F. Kocks and H. Mecking, Physics and Phenomenology of Strain Hardening: The FCC Case, Prog. Mater. Sci., 2003, 48, p 171–273

J. Cuddy and M. Nabil Bassim, Study of Dislocation Cell Structures from Uniaxial Deformation of AISI, 4340 Steel, Mater. Sci. Eng. A, 1989, 113, p 421–429

N. Afrin, D.L. Chen, X. Cao, and M. Jahazi, Strain Hardening Behavior of a Friction Stir Welded Magnesium Alloy, Scr. Mater., 2007, 57, p 1004–1007

W.S. Lee, C. Lin, and B. Chen, Tensile Properties and Microstructural Aspects of 304L Stainless Steel Weldments as a Function of Strain Rate and Temperature, Proc. Inst. Mech. Eng. C, 2005, 219, p 439–451

S. Kim, Y. Im, S. Lee, H. Lee, Y.J. Oh, and J.H. Hong, Effects of Alloying Elements on Mechanical and Fracture Properties of Base Metals and Simulated Heat-Affected Zones of SA 508 Steels, Metall. Mater. Trans. A, 2001, 32, p 903–911

Acknowledgments

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada (NSERC), and Initiative for Automotive Innovation (Ontario Research Fund—Research Excellence) for providing financial support. N. F. thanks Ryerson School of Graduate Studies (SGS) for his SGS scholarship. D. L. C. is also grateful for the financial support by the Premier’s Research Excellence Award (PREA), Canada Foundation for Innovation (CFI), and Ryerson Research Chair (RRC) program. The authors would also like to thank J. Li (University of Waterloo) for providing the welded joints. and Messrs. A. Machin, Q. Li, J. Amankrah, D. Ostrom, and R. Churaman (Ryerson University) for their assistance in the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farabi, N., Chen, D.L. & Zhou, Y. Tensile Properties and Work Hardening Behavior of Laser-Welded Dual-Phase Steel Joints. J. of Materi Eng and Perform 21, 222–230 (2012). https://doi.org/10.1007/s11665-011-9865-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-9865-8