Abstract

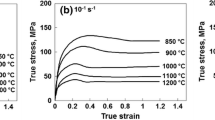

Constitutive equations for the flow behavior of a 0.13 pct C-1.52 pct Mn-0.28 pct Si-0.05 pct Nb-0.052 pct Ti microalloyed steel are determined. For this purpose, uniaxial hot compression tests were performed over a wide range of strain rates (0.01 to 80 s−1) and temperatures (750 to 1050 °C). From microstructural observations, the physical processes that occurred during deformation are discussed and related to the stress-strain responses. Using sinh type constitutive equation, the average apparent activation energy for hot deformation is obtained as 359 kJ/mol. The processing map obtained using the power dissipation efficiency, η, correlates well with microstructural changes observed. In the temperature range of 825-1050 °C and strain rate range of 0.01-0.1 s−1, the strain rate sensitivity map and the power dissipation map exhibit a peak domain wherein dynamic recrystallization is the primary restoration mechanism. Safe domains of strain, strain rate, and temperature for hot working of this steel have been identified.

Similar content being viewed by others

References

F.B.E. Hassani, A. Chenaouia, R. Dkiouak, L. Elbakkali, and A. Al, Omar, Characterization of Deformation Stability of Medium Carbon Microalloyed Steel During Hot Forging Using Phenomenological and Continuum Criteria, J. Mater. Process. Technol., 2008, 199, p 140–149

J.M. Cabrera, A. Al Omar, J.J. Jonas, and J.M. Prado, Modeling the Flow Behavior of a Medium Carbon Microalloyed Steel Under Hot Working Conditions, Metall. Trans. A, 1997, 28, p 2233–2244

Y.V.R.K. Prasad, Processing Maps: A Status Report, J. Mater. Eng. Perform., 2013, 22(10), p 2867–2874

Y.V.R.K. Prasad, Author’s Reply: Dynamic Materials Model: Basis and Principles, Metall. Trans. A, 1996, 27, p 235–236

S.V.S. Narayana Murty, B. Nageswara Rao, and B.P. Kashyap, On the Hot Working Characteristics of 6061Al-SiC and 6061-Al2O3 Particulate Reinforced Metal Matrix Composites, Compos. Sci. Technol., 2003, 63, p 119–135

S.V.S. Narayana Murty, B. Nageswara Rao, and B.P. Kashyap, Development and Validation of a Processing Map for Zirconium Alloys, Model. Simul. Mater. Eng., 2002, 10, p 503–520

S.V.S. Narayana Murty, B. Nageswara Rao, and B.P. Kashyap, On the Hot Working Characteristics of 6061 Al-20 vol.% Al2O3 Metal Matrix Composite, J. Mater. Process. Technol., 2014, 2005(166), p 279–285

S.V.S. Narayana Murty and B. Nageswara Rao, Ziegler’s Criterion on the Instability Regions in Processing Maps, Mater. Sci. Lett., 1998, 17, p 1203–1205

A. Momeni, H. Arabi, A. Rezaei, H. Badri, and H.M. Abbasi, Hot Working Behavior of 2205 Austenite-Ferrite Duplex Stainless Steel Characterized by Constitutive Equations and Processing Maps, Mater. Sci. Eng. A, 2011, 528, p 2158–2163

B. Eghbali and A. Abdollah-zadeh, Influence of Deformation Temperature on the Ferrite Grain Refinement in a Low Carbon Nb-Ti Microalloyed Steel, J. Mater. Process. Technol., 2006, 180, p 44–48

M. Li-qiang, L. Zhen-yu, J. Si-hai, Y. Xiang-qian, and W. Di, Effect of Niobium and Titanium on Dynamic Recrystallization Behavior of Low Carbon Steels, J. Iron Steel Res. Int., 2008, 15(3), p 31–36

O. Kwon and A.J. De Ardo, Interactions Between Recrystallization and Precipitation in Hot-Deformed Microalloyed Steels, Acta Metall. Mater., 1991, 39, p 529–538

C. Jian-chun, L. Qing-you, Y. Qi-long, and S. Xin-jun, Effect of Niobium on Isothermal Transformation of Austenite to Ferrite in HSLA Low-Carbon Steel, J. Iron Steel Res. Int., 2007, 14(3), p 51–55

M. Opiela and A. Grajcar, Hot Deformation Behavior and Softening Kinetics of Ti-V-B Microalloyed Steels, Arch. Civil Mech. Eng., 2012, 12, p 327–333

H. Zhao, G. Liu, and L. Xu, Rate-Controlling Mechanisms of Hot Deformation in a Medium Carbon Vanadium Microalloy Steel, Mater. Sci. Eng. A, 2013, 559, p 262–267

H. Wei, G. Liu, X. Xiao, H. Zhao, H. Ding, and R. Kang, Characterization of Hot Deformation Behavior of a New Microalloyed C-Mn-Al High-Strength Steel, Mater. Sci. Eng. A, 2013, 564, p 140–146

S.F. Medina and C.A. Hernandez, The Influence of Chemical Composition on Peak Strain of Deformed Austenite in Low Alloy and Microalloyed Steels, Acta Mater., 1996, 44(1), p 149–154

S.F. Medina and C.A. Hernandez, General Expression of the Zener-Hollomon Parameter as a Function of the Chemical Composition of Low Alloy and Microalloyed Steels, Acta Mater., 1996, 44(1), p 137–148

M. Calcagnotto, D. Ponge, and D. Raabe, Effect of Grain Refinement to 1 µm Strength and Toughness of Dual-Phase Steels, Mater. Sci. Eng. A, 2010, 527, p 7832–7840

S.F. Medina and C.A. Hernandez, Modelling of the Dynamic Recrystallization of Austenite in Low Alloy and Microalloyed Steels, Acta Mater., 1996, 44, p 165–171

B. Eghbali and A. Abdollah-Zadeh, Strain-Induced Transformation in a Low Carbon Microalloyed Steel During Hot Compression Testing, Scripta Mater., 2006, 54, p 1205–1209

S.Q. Yuan and G.L. Liang, Dissolving Behaviour of Second Phase Particles in Nb-Ti Microalloyed Steel, Mater. Sci. Lett., 2009, 63, p 2324–2326

B. Eghbali and A. Abdollah-Zadeh, Deformation-Induced Ferrite Transformation in a Low Carbon Nb-Ti Microalloyed Steel, Mater. Des., 2007, 28, p 1021–1026

A.I. Fernández, P. Uranga, B. López, and J.M. Rodriguez-Ibabe, Dynamic Recrystallization Behavior Covering a Wide Austenite Grain Size Range in Nb and Nb-Ti Microalloyed Steels, Mater. Sci. Eng. A, 2003, 361, p 367–376

Y. Cao, F. Xiao, G. Qiao, X. Zhang, and B. Liao, Quantitative Research on Effects of Nb on hot Deformation Behaviors of High-Nb Microalloyed Steels, Mater. Sci. Eng. A, 2011, 530, p 277–284

S.F. Medina and J.E. Mancill, Influence of Alloying Elements in Solution on Static Recrystallization Kinetics of Hot Deformed Steels, ISIJ Int., 1996, 36(8), p 1063–1069

A. Ghosh, S. Das, S. Chatterjee, B. Mishra, and P.R. Rao, Influence of Thermo-Mechanical Processing and Different Post-Cooling Techniques on Structure and Properties of an Ultra Low Carbon Cu Bearing HSLA Forging, Mater. Sci. Eng. A, 2003, 348, p 299–308

S.C. Hong and K.S. Lee, Influence of Deformation Induced Ferrite Transformation on Grain Refinement of Dual Phase Steel, Mater. Sci. Eng. A, 2002, 323, p 148–159

A.Z. Hanzaki, R. Pandi, P.D. Hodgson, and S. Yue, Continuous Cooling Deformation Testing of Steels, Metall. Trans. A, 1993, 24, p 2657–2665

B. Eghbali, Study on the Ferrite Grain Refinement During Intercritical Deformation of a Microalloyed Steel, Mater. Sci. Eng. A, 2010, 527, p 3407–3410

R.K. Gupta, S.V.S. Narayana Murty, B. Pant, V. Agarwala, and P.P. Sinha, Hot Workability of γ + α2 Titanium Aluminide: Development of Processing Map and Constitutive Equations, Mater. Sci. Eng. A, 2012, 551, p 169–186

B. Chen, W. Zhou, S. Li, X.L. Li, and C. Lu, Hot Compression Deformation Behavior and Processing Maps of Mg-Gd-Y-Zr Alloy, J. Mater. Eng. Perform., 2013, 20(9), p 2458–2466

H. Ziegler, E. Becker, B. Budiansky, H.A. Lauwerier, and T. Koiter, An Introduction to Thermodynamics, 2nd ed., North-Holland Publishing Company, New York, 1983

F. Montheillet, J.J. Jonas, and K.W. Neale, Modeling of Dynamic Material Behavior: A Critical Evaluation of the Dissipator Power co-content Approach, Metall. Trans. A, 1996, 27, p 232–235

A.R. Maldar, G.R. Ebrahimi, M. Haghshenas, M. Jahazi, and P. Bocher, Thermomechanical Characterization of Mg-9Al-1Zn Alloy Using Power Dissipation Maps, J. Mater. Eng. Perform., 2013, 22(11), p 3306–3314

Y.H. Duan, Hot Deformation and Processing Map of Pb-Mg-10Al-1B Alloy, J. Mater. Eng. Perform., 2013, 20(10), p 3049–3054

C. Poletti, J. Six, M. Hochegger, H.P. Degischer, and S. Ilie, Hot Deformation Behaviour of Low Alloy Steel, Steel Res. Int., 2011, 82, p 710–718

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14, p 1136–1138

H.J. McQueen, S. Yue, N.D. Ryan, and E. Fry, Hot Working Characteristics of Steels in Austenitic State, J. Mater. Process. Technol., 1995, 53, p 293–310

H.J. McQueen, Elevated Temperature Deformation at Forming Rates of 10−2 to 102 s−1, Metall. Trans. A, 2002, 33, p 345–362

Dynamic Systems Inc. Elimination of Load Cell Ringing During High Speed Deformation by Mathematical Treatment, Application note, New York, 2001

T. Sakai, Dynamic Recrystallization Microstructures Under Hot Working Conditions, J. Mater. Process. Technol., 1995, 53, p 349–361

D.Q. Bai, Y. Yue, T.M. Maccagno, and J.J. Jonas, Continuous Cooling Transformation Temperatures Determined by Compression Tests in Low Carbon Bainitic Grades, Metall. Trans. A, 1998, 29, p 989–1001

B. Verlinden, J. Driver, I. Samajdar, and R.D. Doherty, Thermo-Mechanical Processing of Metallic Materials, 1st ed., Pergamon Materials Series, Oxford, 2007

M.C. Zhao, K. Yang, F.R. Xiao, and Y.Y. Shan, Continuous Cooling Transformation of Undeformed and Deformed Low Carbon Pipeline Steels, Mater. Sci. Eng. A, 2003, 355, p 126–136

S.M. Abbasi and A. Momeni, Hot Working Behavior of Fe-29Ni-17Co Analyzed by Mechanical Testing and Processing Map, Mater. Sci. Eng. A, 2012, 552, p 330–335

S.K. Rajput, M. Dikovits, G.P. Chaudhari, C. Poletti, F. Warchomicka, V. Pancholi, and S.K. Nath, Physical Simulation of Hot Deformation and Microstructural Evolution of AISI, 1016 Steel Using Processing Maps, Mater. Sci. Eng. A, 2013, 587, p 291–300

J.J. Jonas, R.A. Holt, and C.E. Coleman, Plastic Stability in Tension and Compression, Acta Metall., 1976, 24, p 911–918

A.F. Gourgues, H.M. Flower, and T.C. Lindley, Electron Backscattering Diffraction Study of Acicular Ferrite, Bainite, and Martensite Steel Microstructures, Mater. Sci. Technol., 2000, 16, p 26–40

A. Smolej, B. Skaza, and M. Fazarinc, Determination of the Strain-Rate Sensitivity and the Activation Energy of Deformation in the Superplastic Aluminium Alloy Al-Mg-Mn-Sc, Mater. Geoenviron., 2009, 56, p 389–399

J. Liu, H. Chang, R. Wu, T.Y. Hsu, and X. Ruan, Investigation on Hot Deformation Behavior of AISI, T1 High-Speed Steel, Mater. Charact., 2000, 45, p 175–186

H. Mirzadeh, J.M. Cabrera, J.M. Prado, and A. Najafizadeh, Hot Deformation Behavior of a Medium Carbon Microalloyed Steel, Mater. Sci. Eng. A, 2011, 528, p 3876–3882

X. Fu-ren, C. Ya-bin, Q. Gui-ying, Z. Xiao-bing, and L. Bo, Effect of Nb Solute and NbC Precipitates on Dynamic or Static Recrystallization in Nb Steels, J. Iron Steel Res. Int., 2012, 19(11), p 52–56

Acknowledgments

The authors are grateful for the support received under the DST-BMWF, ÖAD Indo-Austrian scientific cooperation scheme. In addition, the authors would like to thank Dr. Cecilia Poletti and Martina Dikovits of Technical University, Graz, Austria for help in conducting the high strain rate compression tests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajput, S.K., Chaudhari, G.P. & Nath, S.K. Physical Simulation of Hot Deformation of Low-Carbon Ti-Nb Microalloyed Steel and Microstructural Studies. J. of Materi Eng and Perform 23, 2930–2942 (2014). https://doi.org/10.1007/s11665-014-1059-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1059-8