Abstract

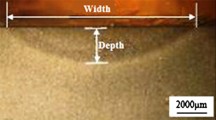

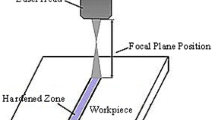

The study investigates laser surface hardening in the AISI 1045 steel using two different types of industrial laser: a high-power diode laser (HPDL) and a CO2 laser, respectively. The effect of process parameters such as beam power, travel speed on structure, case depth, and microhardness was examined. In most cases, a heat-affected zone (HAZ) formed below the surface; a substantial increase in surface hardness was achieved. In addition, big differences were found between the hardened specimens after HPDL surface hardening and CO2 laser surface hardening. For HPDL, depths of the HAZ were almost equal in total HAZ o, without surface melting. For CO2 laser, the depths changed a lot in the HAZ, with surface melting in the center. To better understand the difference of laser hardening results when use these two types of laser, numerical (ANSYS) analysis of the heat conduction involved in the process was also studied. For HPDL method, a rectangular beam spot and uniform energy distribution across the spot were assumed, while for CO2 laser, a circular beam spot and Gaussian energy distribution were assumed. The results showed that the energy distribution variety altered the thermal cycles of the HAZ dramatically. The rectangular HPDL laser beam spot with uniform energy distribution is much more feasible for laser surface hardening.

Similar content being viewed by others

References

G.E. Totten, K. Funatani, and L. Xie, Handbook of Metallurgical Process Design: Laser Surface Hardening, CRC Press, Florida, 2006

W.M. Steen and J. Mazumder, Laser Material Processing, Springer, London, 2010

S.M. Shariff, T.K. Pal, G. Padmanabham, and S.V. Joshi, Influence of Chemical Composition and Prior Microstructure on Diode Laser Hardening of Railroad Steels, Surf. Coat. Technol., 2013, 228, p 14–26

G. Tani, A. Fortunato, A. Ascari, and G. Campana, Laser Surface Hardening of Martensitic Stainless Steel Hollow Parts, CIRP Ann. Manuf. Technol., 2010, 59, p 207–210

L. Orazi, A. Fortunato, G. Cuccolini, and G. Tani, An Efficient Model for Laser Surface Hardening of Hypo-eutectoid Steels, Appl. Surf. Sci., 2010, 256, p 1913–1919

F. Lusquiños, J.C. Conde, S. Bonss, A. Riveiro, F. Quintero, R. Comesaña, and J. Pou, Theoretical and Experimental Analysis of High Power Diode Laser (HPDL) Hardening of AISI, 1045 Steel, Appl. Surf. Sci., 2007, 254, p 948–954

H. Hagino, S. Shimizu, H. Ando, and H. Kikuta, Design of a Computer-Generated Hologram for Obtaining a Uniform Hardened Profile by Laser Transformation Hardening with a High-Power Diode Laser, Precis. Eng., 2010, 34, p 446–452

A.I. Katsamas and G.N. Haidemenopoulos, Surface Hardening of Low-Alloy 15CrNi6 Steel by CO2 Laser Beam, Surf. Coat. Technol., 1999, 115, p 249–255

M. Pellizzari and M.G. De Flora, Influence of Laser Hardening on the Tribological Properties of Forged Steel for Hot Rolls, Wear, 2011, 271, p 2402–2411

C. Soriano, J. Leunda, J. Lambarri, V. García Navas, and C. Sanz, Effect of Laser Surface Hardening on the Microstructure, Hardness and Residual Stresses of Austempered Ductile Iron Grades, Appl. Surf. Sci., 2011, 257, p 7101–7106

A. Fortunato, A. Ascari, L. Orazi, G. Campana, and G. Cuccolini, Numerical Evaluation of the Reflectivity Coefficient in Laser Surface Hardening Simulation, Surf. Coat. Technol., 2012, 206, p 3179–3185

G. Telasang, J. DuttaMajumdar, G. Padmanabham, and I. Manna, Structure–Property Correlation in Laser Surface Treated AISI, H13 Tool Steel for Improved Mechanical Properties, Mater. Sci. Eng. A, 2014, 599, p 255–267

R. Komanduri and Z.B. Hou, Thermal Analysis of Laser Surface Transformation Hardening—Optimization of Process Parameters, Int. J. Mach. Tool. Manuf., 2004, 44, p 991–1008

S. Safdar, L. Li, M.A. Sheikh, and Z. Liu, An Analysis of the Effect of Laser Beam Geometry on Laser Transformation Hardening, J. Manuf. Sci. Eng., 2006, 128, p 659–667

C. Zeng, W. Tian, and L. Hua, A Comprehensive Study of Thermal Damage Consequent to Laser Surface Treatment, Mater. Sci. Eng. A, 2013, 564, p 381–388

A. Laazizi, B. Courant, F. Jacquemin, and H. Andrzejewski, Applied Multi-Pulsed Laser in Surface Treatment and Numerical–Experimental Analysis, Opt. Laser Technol., 2011, 43, p 1257–1263

X.F. Wang, X.D. Lu, G.N. Chen, ShG Hu, and Y.P. Su, Research on the Temperature Field in Laser Hardening, Opt. Laser Technol., 2006, 38, p 8–13

J. Winczek, New Approach to Modeling of Temperature Field in Surfaced Steel Elements, Int. J. Heat Mass Transfer, 2011, 54, p 4702–4709

S. Elangovan, S. Semeer, and K. Prakasan, Temperature and Stress Distribution in Ultrasonic Metal Welding-An FEA-Based Study, J. Mater. Process. Technol., 2009, 209, p 1143–1150

J. Grum, Comparison of Different Techniques of Laser Surface Hardening, J. Achiev. Mater. Manuf. Eng., 2007, 24, p 17–25

F. Bachmann, P. Loosen, and R. Poprawe, High Power Diode Lasers: Technology and Applications, Springer, Michgan, 2006

G.F. Vander Voort, Atlas of Time-Temperature Diagrams for Irons and Steels, ASM, International, Materials Park, 1991

Zhiyue Xu, Claude B. Reed, Keng H. Leong, Boyd V. Hunters, Proceedings of the International Conference on Applications of Lasers and Electro-Optics (ICALEO’99) San Diego, CA, November 15–18, 1999

Acknowledgments

The author would like to thank the financial support provided by the the Natural Science Foundation of Jiangsu Province (BK20130469) and the Natural Science Research Program for Higher Education in Jiangsu Province (13KJB430009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, R., Jin, Y., Li, Z. et al. A Comparative Study of High-Power Diode Laser and CO2 Laser Surface Hardening of AISI 1045 Steel. J. of Materi Eng and Perform 23, 3085–3091 (2014). https://doi.org/10.1007/s11665-014-1146-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1146-x