Abstract

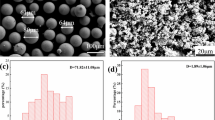

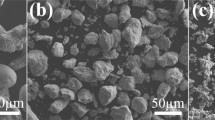

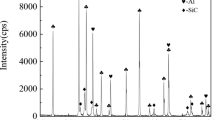

The present study focuses on the effect of different Cr/C ratios on the microstructure, microhardness, and corrosion resistance of Ni-based laser clad hardfacings, reinforced by in situ synthesized chromium carbide particles. Cr3C2-NiCr composites have been laser processed with graphite/Cr/Ni powder blends with varying Cr/C ratios. Following phase analysis (x-ray diffraction) and microstructure investigation (scanning electron microscopy; energy dispersive x-ray analysis; transmission electron microscopy), the solidification of laser melt pool is discussed, and the corrosion resistances are examined. Several different zones (planar, dendritic, eutectic and re-melt zone) were formed in these samples, and the thicknesses and shapes of these zones vary with the change of Cr/C ratio. The sizes and types of carbides and the content of reserved graphite in the composites change as the Cr/C ratio varies. With the content of carbides (especially Cr3C2) grows, the microhardness is improved. The corrosive resistance of the composites to 0.2M H2SO4 aqueous solution decreases as the Cr/C ratio reduces owing to not only the decreasing Cr content in the NiCr matrix but also the galvanic corrosion formed within the carbide and graphite containing Ni matrix.

Similar content being viewed by others

References

J. Morimoto, Y. Sasaki, S. Fukuhara, N. Abe, and M. Tukamoto, Surface Modification of Cr3C2-NiCr Cermet Coatings by Direct Diode Laser, Vacuum, 2006, 80, p 1400–1405

A. Bondar, A. Velikanova, and T. Ya, Phase Equilibria in the Cr-Ni-C System and Their Use for Developing Physicochemical Principles for Design of Hard Alloys Based on Chromium Carbide, Powder Metall. Met. Ceram., 1997, 36, p 242–252

C.M. Chang, C.M. Lin, and C.C. Hsieh, Effect of Carbon Content on Microstructural Characteristics of the Hypereutectic Fe-Cr-C Claddings, Chem. Phys., 2009, 117, p 257–261

C.M. Chang, L.H. Chen, and W. Wu, Microstructure and wear Characteristics of Hypereutectic Fe-Cr-C Cladding with Various Carbon Contents, Surf. Coat. Technol., 2010, 205, p 245–250

C.M. Chang, C.C. Hsieh, C.M. Lin, J.H. Chen, C.M. Fan, and W. Wu, Effect of Carbon Content on Microstructure and Corrosion Behavior of Hypereutectic Fe-Cr-C Claddings, Mater. Chem. Phys., 2010, 123(1), p 241–246

J. Choi and J. Mazumder, Non-Equilibrium Synthesis of Fe-Cr-C-W Alloy by Laser Cladding, J. Mater. Sci., 1994, 29, p 4460–4476

S. Harsha, D.K. Dwivedi, and A. Agarwal, Influence of CrC Addition in Ni-Cr-Si-B Flame Sprayed Coatings on Microstructure, Microhardness and Wear Behavior, Int. J. Adv. Manuf. Technol., 2008, 38, p 93–101

P. Berthod, P. Lemoine, and L. Aranda, Experimental and Thermodynamic Study of Nickel-Based Alloys Containing Chromium Carbides, Part I: Study of the Ni-30 wt.%Cr-xC System Over the [0-2.0 wt.%C] Range, Calphad, 2008, 32, p 485–491

R. Thompson and D. Lemkey, Unidirectional Solidification of Co-Cr-C Mono Variant Eutectic Alloys, Metall. Trans. B, 1970, 1, p 2799–2806

S.H. Si, K. Xu, Y.L. Liu, and H.X. Zhou, Microstructure and Performance of Laser Cladding Co+Cr3C2 Composite Coating, Trans. China Weld. Inst., 2006, 27, p 45–49

G. Barbezat, R. Nicol, and A. Sickinger, Abrasion Erosion and Scuffing Resistance of Carbide and Oxide Ceramic Thermal Sprayed Coatings for Different Applications, Wear, 1993, 162, p 529–537

S. Matthews, B. James, and M. Hyland, Erosion of Oxide Scales Formed on Cr3C2-NiCr Thermal Spray Coatings, Corros. Sci., 2001, 50, p 3087–3094

T. Kunioshi, V. Correa, and V. Ramanathan, High Temperature Oxidation and Erosion-Oxidation Behavior of HVOF Sprayed Ni-20Cr, WC-20Cr-7Ni, Cr3C2 -NiC20Cr Coatings, Surf. Eng., 2006, 22, p 121–127

H. Staia, T. Valente, C. Bartuli, and B. Lewis, Part II: Tribological Performance of Cr3C2-25%NiCr Reactive Plasma Sprayed Coatings Deposited at Different Pressures, Surf. Coat. Technol., 2001, 146, p 563–570

A.G. Liu, M.H. Guo, H.L. Hu, and Z.J. Li, Microstructure of Cr3C2-Reinforced Surface Metal Matrix Composite Produced by Gas Tungsten arc Melting Injection, Scr. Mater., 2008, 59, p 231–234

G.F. Sun, Y. Zhang, and C.S. Liu, Microstructure and Wear Resistance Enhancement of Cast Steel Rolls by Laser Surface Alloying NiCr-Cr3C2, Mater. Des., 2010, 31, p 2737–2744

J.C. Betts, The Direct Laser Deposition of AISI316 Stainless Steel and Cr3C2 Powder, J. Mater. Process. Technol., 2009, 209, p 5229–5238

G. Xie, Y. Lu, Z. He, B. Hu, K. Wang, X. Mo, Y. Wu, and P. Lin, Microstructure and Corrosion Properties of Plasma Sprayed NiCr-Cr3C2 Coatings Comparison with Different Post Treatment, Surf. Coat. Technol., 2008, 202, p 2885–2890

J. Davis, Metals Handbook Desk Edition, 2nd ed., ASM International, New York, 1998.

H. Tan, J. Chen, and F. Zhang, Texture Control During Laser Deposition of Nickel-Based Superalloy, Opt. Laser Technol., 2010, 42, p 47–54

P. Dinda, K. Dasgupta, and J. Mazumder, Texture Control During Laser Deposition of Nickel-Based Superalloy, Scr. Mater., 2012, 67, p 503–506

F. Liu, X. Lin, C. Huang, M. Song, G. Yang, J. Chen, and W. Huang, The Effect of Laser Scanning Path on Microstructures and Mechanical Properties of Laser Solid Formed Nickel-Base Superalloy Inconel 718, J. Alloys. Compd., 2011, 509, p 4505–4509

A. Karma and A. Sarkissian, On the Formation of the Banded Structure in Solidification, Mater. Sci. Eng. A, 1994, 178, p 153–157

X. Lin, “Evolution and Selection of Micro Substructure in Solidification”, Ph.D. Thesis, China, 2000, p 28–30.

E. Blank and E. Luchsinger, Microstructure and Abrasive Wear Resistance of Cast Ni-Cr-C Alloys, Wear, 1987, 117, p 289–308

D.Y. Lou, C.L. He, S. Shang, C.S. Liu, and Q.K. Cai, Microstructure and Performances of Graphite Scattered Cr3C2-NiCr Composites Prepared by Laser Processing, Mater. Lett., 2013, 93, p 304–307

P. Villars, A. Prince, and H. Okamoto, Handbook of Ternary Alloy Phase Diagram, ASM International, New York, 1995.

Y. Velikanova, A. Bondar, and V. Grytsiv, The Chromium-Nickel-Carbon (Cr-Ni-C) Phase Diagram, J. Phase Equilib., 1999, 20, p 125–147

M. Sherif, A. Almajid, F. Hamdan, and J. Harri, Effects of Graphite on the Corrosion Behavior of Aluminum Graphite Composite in Sodium Chloride Solutions, Int. J. Electrochem. Sci., 2011, 6, p 1085–1099

W. Tucker, R. Brown, and L. Russell, Corrosion Between a Graphite/Polymer Composite and Metals, J. Compos. Mater., 1990, 24, p 92–102

B. Szczygieł and M. Kołodziej, Composite Ni/Al2O3 Coatings and Their Corrosion Resistance, Electrochim. Acta, 2005, 50, p 4188–4195

Acknowledgments

This research was financially supported by the National Natural Science Foundation of P. R. China (51171118, 11204071/A040405) and Research Project of HBUT (337234).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lou, D., Liu, D., He, C. et al. Effect of Cr/C Ratio on Microstructure and Corrosion Performance of Cr3C2-NiCr Composite Fabricated by Laser Processing. J. of Materi Eng and Perform 25, 312–319 (2016). https://doi.org/10.1007/s11665-015-1843-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1843-0