Abstract

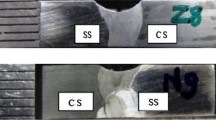

The specific activated flux has been developed for enhancing the penetration performance of TIG welding process for autogenous welding of type 304LN and 316LN stainless steels through systematic study. Initially single-component fluxes were used to study their effect on depth of penetration and tensile properties. Then multi-component activated flux was developed which was found to produce a significant increase in penetration of 10-12 mm in single-pass TIG welding of type 304LN and 316LN stainless steels. The significant improvement in penetration achieved using the activated flux developed in the present work has been attributed to the constriction of the arc and as well as reversal of Marangoni flow in the molten weld pool. The use of activated flux has been found to overcome the variable weld penetration observed in 316LN stainless steel with <50 ppm of sulfur. There was no degradation in the microstructure and mechanical properties of the A-TIG welds compared to that of the welds produced by conventional TIG welding on the contrary the transverse strength properties of the 304LN and 316LN stainless steel welds produced by A-TIG welding exceeded the minimum specified strength values of the base metals. Improvement in toughness values were observed in 316LN stainless steel produced by A-TIG welding due to refinement in the weld microstructure in the region close to the weld center. Thus, activated flux developed in the present work has greater potential for use during the TIG welding of structural components made of type 304LN and 316LN stainless steels.

Similar content being viewed by others

References

K.C. Mills and B.J. Keene, Factors Affecting Variable Penetration, Int. Mater. Rev., 1990, 35(4), p 185–216

W. Lucas and D.S. Howse, Activating Flux—Increasing the Performance and Productivity of the TIG and Plasma Processes, Weld. Met. Fabr., 1996, 64(1), p 11–17

T. Paskell, C. Lundin, and H. Castner, GTAW Flux Increases Weld Joint Penetration, Weld. J., 1997, 76(4), p 57–62

P.J. Modenesi, E.R. Apolinario, and I.M. Pereira, TIG Welding with Single-Component Fluxes, J. Mater. Process. Technol., 2000, 99(1–3), p 260–265

M. Tanaka, T. Shimizu, H. Terasaki, M. Ushio, C.L. Koshiishi, and C.L. Yang, Effects of Activating Flux on Arc Phenomena in Gas Tungsten Arc Welding, Sci. Technol. Weld. Join., 2000, 5(6), p 397–402

P.C.J. Anderson and R. Wiktorowicz, Improving productivity with A-TIG welding, Weld. Met. Fabr., 1996, 64(3), p 108–109

D. Fan, R. Zhang, Y. Gu, and M. Ushio, Effect of Flux on A-TIG Welding of Mild Steels, Trans. JWRI, 2001, 30, p 35–40

C.R. Heiple and J.R. Roper, Mechanism for Minor Element Effect on GTA Fusion Zone Geometry, Weld. J., 1982, 61(4), p 97s–102s

S.W. Pierce, P. Burgardt, and D.L. Olson, Thermocapillary and Arc Phenomena in Stainless Steel Welding, Weld. J., 1999, 78(2), p 45s–52s

S. Lu, H. Fujii, H. Sugiyama, and K. Nogi, Mechanism and Optimisation of Oxide Fluxes For Deep Penetration in Gas Tungsten Arc Welding, Metall. Mater. Trans. A, 2003, 34A, p 1901–1907

H.Y. Huang, S.W. Shyu, K.H. Tseng, and C.P. Chou, Evaluation of TIG Flux Welding on the Characteristics of Stainless Steel, Sci. Technol. Weld. Join., 2005, 10(5), p 566–573

A. Rodrigues and A. Loureiro, Effect of Shielding Gas and Activating Flux on Weld Bead Geometry in Tungsten Inert Gas Welding of Austenitic Stainless Steel, Sci. Technol. Weld. Join., 2005, 10(6), p 760–765

S. Leconte, P. Paillard, and J. Saindrenan, Effect of Fluxes Containing Oxides on Tungsten Inert Gas Welding Process, Sci. Technol. Weld. Join., 2006, 11(1), p 43–47

L. Sanbao, Y. Chunli, L. Fengyao, W. Lin, and S. Sheng, Effect of Activating Fluxes on Weld Mechanical Properties in TIG Welding, China Weld., 2001, 10(2), p 46–50

M. Vasudevan, Computational and Experimental Studies on Arc Welded Stainless Steels. Ph.D. Thesis, Indian Institute of Technology, Madras, Chennai, 2007

T. Sakthivel, M. Vasudevan, K. Laha, P. Parameswaran, K.S. Chandravathi, M.D. Mathew, and A.K. Bhaduri, Effect of Welding Processes on the Creep Rupture Behaviour of type 316LN Stainless Steel Weld Joints, Mater. Sci. Eng. A, 2011, 528(22–23), p 6971–6980

V. Maduraimuthu, M. Vasudevan, V. Muthupondi, A.K. Bhaduri, and T. Jayakumar, Study of the Effect of Activated Flux on the Microstructure and Mechanical Properties of Mod. 9Cr–1Mo steel, Metall. Mater. Trans. B, 2012, 43(1), p 123–132

P. Palanichamy, M. Vasudevan, and T. Jayakumar, Measurement of Residual Stresses in Austenitic Stainless Steel Weld Joints Using an Ultrasonic technique, Sci. Technol. Weld. Join., 2009, 14(2), p 166–171

P. Vasantharaja, V. Maduraimuthu, M. Vasudevan, and P. Palanichamy, Measurement of Residual Stresses in Austenitic Stainless Steel Weld Joints Using an Ultrasonic Technique, Mater. Manuf. Process., 2012, 27(12), p 1376–1381

A. Ravishankar, S. Niyanth, M. Vasudevan, and K. Mudali, Microstructural Characterization and Corrosion behaviour of type 304 L Stainless Steel TIG weld joints in Nitric Acid, Corrosion, 2012, 68(8), p 762–773

M. Vasudevan, A.K. Bhaduri, and B. Raj, A Penetration Enhancing Flux Formulation For Tungsten Inert Gas (TIG) Welding of Austenitic Stainless Steel and Its Application. United States Patent No. 8097826 B2, 17 Jan 2012

M. Vasudevan, A.K. Bhaduri, and B. Raj, A Penetration Enhancing Flux Formulation for Tungsten Inert Gas (TIG) Welding of Austenitic Stainless Steel and Its Application. United Kingdom Patent No. GB 2446905 B, 16 Feb 2011

Y. Zhao, H. Zhou, and Y. Shi, The Study of Surface Active Element on Weld Pool Development in A-TIG Welding, Model. Simul. Mater. Sci. Eng., 2006, 14, p 331–349

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vasudevan, M. Effect of A-TIG Welding Process on the Weld Attributes of Type 304LN and 316LN Stainless Steels. J. of Materi Eng and Perform 26, 1325–1336 (2017). https://doi.org/10.1007/s11665-017-2517-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2517-x