Abstract

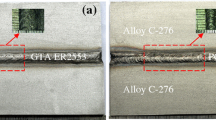

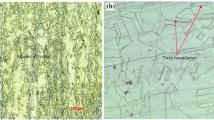

In the present investigation, an attempt has been made to join Hastelloy C-276 nickel-based superalloy and AISI 321 austenitic stainless steel using ERNiCrMo-4 filler. The joints were fabricated by continuous and pulsed current gas tungsten arc welding processes. Experimental studies to ascertain the structure-property co-relationship with or without pulsed current mode were carried out using an optical microscope and scanning electron microscope. Further, the energy-dispersive spectroscope was used to evaluate the extent of microsegregation. The microstructure of fusion zone was obtained as finer cellular dendritic structure for pulsed current mode, whereas columnar structure was formed with small amount of cellular structure for continuous current mode. The scanning electron microscope examination witnessed the existence of migrated grain boundaries at the weld interfaces. Moreover, the presence of secondary phases such as P and μ was observed in continuous current weld joints, whereas they were absent in pulsed current weld joints, which needs to be further characterized. Moreover, pulsed current joints resulted in narrower weld bead, refined morphology, reduced elemental segregation and improved strength of the welded joints. The outcomes of the present investigation would help in obtaining good quality dissimilar joints for industrial applications and AISI 321 ASS being cheaper consequently led to cost-effective design also.

Similar content being viewed by others

References

J. Verma, R.V. Taiwade, R.K. Khatirkar, S.G. Sapate, and A.D. Gaikwad, Microstructure, Mechanical and Intergranular Corrosion Behaviour of Dissimilar DSS 2205 and ASS 316L Shielded Metal Arc Welds, Trans. Indian Inst. Met., 2016, doi:10.1007/s12666-016-0878-8

D. Bhattacharyya, J. Davis, M. Drew, R.P. Harrison, and L. Edwards, Characterization of Complex Carbide-Silicide Precipitates in a Ni-Cr-Mo-Fe-Si Alloy Modified by Welding, Mater. Charact., 2015, 105, p 118–128

V.A. Ventrella, J.R. Berretta, and W.D. Rossi, Pulsed Nd: YAG Laser Welding of Ni-Alloy Hastelloy C-276 Foils, Phys. Proced., 2012, 39, p 569–576

K.K. Mehta, P. Mukhopadhyay, R.K. Mandal, and A.K. Singh, Mechanical Properties Anisotropy of Cold-Rolled and Solution-Annealed Ni-Based Hastelloy C-276 Alloy, Metall. Mater. Trans. A, 2014, 45A, p 3493–3504

Y. Ma, Y. Xu, S. Zhang, and C. Lu, Evaluation of Mechanical Properties of Hastelloy C-276 Weld By Small Punch Test, Adv. Mater. Res., 2014, 941–944, p 1483–1487

H.M. Tawancy, Long-Term Ageing Characteristics of Some Commercial Nickel–Chromium–Molybdenum Alloy, J. Mater. Sci., 1981, 16, p 2883–2889

M. Manikandan, P.R. Hari, G. Vishnu, M. Arivarasu, R.K. Devendranath, N. Arivazhagan, R.M. Nageswara, and G.M. Reddy, Investigation of Microstructure and Mechanical Properties of Super Alloy C-276 by Continuous Nd: YAG Laser Welding, Proced. Mater. Sci., 2014, 5, p 2233–2241

M. Manikandan, N. Arivazhagan, M.N. Rao, and G.M. Reddy, Improvement of Microstructure and Mechanical Behaviour of Gas Tungsten Arc Weldments of Alloy C-276 by Current Pulsing, Acta Metall. Sin., 2015, 28, p 208–215

S.A.A.A. Mousavi and A.R. Sufizadeh, Metallurgical Investigations of Pulsed Nd: YAG Laser Welding of AISI, 321 and AISI, 630 Stainless Steels, Mater. Des., 2009, 30, p 3150–3157

G. Sayiram and N. Arivazhagan, Microstructural Characterization of Dissimilar Welds Between Incoloy 800H and 321 Austenitic Stainless Steel, Mater. Charact., 2015, 102, p 180–188

R. Yilmaz and M. Tumer, Microstructural Studies and Impact Toughness of Dissimilar Weldments Between AISI, 316 and AH36 Steels by FCAW, Int. J. Adv. Manuf. Tech., 2013, 67, p 1433–1447

V. Rajkumar and N. Arivazhagan, Role of Pulsed Current on Metallurgical and Mechanical Properties of Dissimilar Metal Gas Tungsten Arc Welding of Maraging Steel to Low Alloy Steel, Mater. Des., 2014, 63, p 69–82

F. Tariq, A.R. Baloch, B. Ahmed, and N. Naz, Investigation into Microstructures of Maraging Steel 250 Weldments and Effect of Post-weld Heat Treatments, J. Mater. Eng. Perform., 2010, 19, p 264–273

I. Hajiannia, M. Shamanian, and M. Kasiri, Microstructure and Mechanical Properties of AISI, 347 Stainless Steel/A335 Low Alloy Steel Dissimilar Joint Produced by Gas Tungsten Arc Welding, Mater. Des., 2013, 50, p 566–573

N. Arivazhagan, S. Singh, S. Prakash, and G.M. Reddy, Investigation of AISI, 304 Austenitic Stainless Steel to AISI, 4140 Low Alloy Steel Dissimilar Joints by Gas Tungsten Arc, Electron Bean and Friction Welding, Mater. Des., 2011, 32, p 3036–3050

M. Ahmad, J.I. Akhter, M. Akhtar, M. Iqbal, E. Ahmed, and M.A. Choudhry, Microstructure and Hardness Studies of the Electron Beam Welded Zone of Hastelloy C-276, J. Alloy. Compd., 2005, 390(1–2), p 88–93

M.J. Cieslak, T.J. Headley, and A.D. Roming, The Welding Metallurgy of Hastelloy Alloys C-4, C-22 and C-276, Metall. Mater. Trans. A, 1986, 17A, p 2035–2047

G. Green, R. Higginson, S. Hogg, S. Spindler, and C. Hamm, Evolution of Sigma Phase in 321 Grade Austenitic Stainless Steel Parent and Weld Metal with Duplex Microstructure, Mater. Sci. Tech., 2014, 30(12), p 1392–1398

J.N. Dupont, S.W. Banovic, and A.R. Marder, Microstructural Evolution and Weldability of Dissimilar Welds Between a Super Austenitic Steel and Nickel-Based Alloys, Weld. J., 2003, 82, p 125s–135s

G. Ma, D. Wu, and D. Guo, Segregation Characteristics of Pulsed Laser Butt Welding of Hastelloy C-276, Metall. Mater. Trans. A, 2011, 42A, p 3853–3857

M. Hashim, K.E.S.R. Babu, M. Duraiselvam, and H. Natu, Improvement of Wear Resistance of Hastelloy C-276 Through Laser Surface Melting, Mater. Des., 2013, 46, p 546–551

K.D. Ramkumar, R.J. Sai, G. Sridhar, V.S. Reddy, P. Prabaharan, N. Arivazhagan, and N. Sivashanmugham, Influence of Filler Metals in the Control of Deleterious Phases During the Multi-pass Welding of Inconel 718 Plates, Acta Metall. Sin., 2014, 28, p 196–207

R.M. Indira and R.N. Marpu, Effect of Pulsed Current TIG Welding Parameters on Mechanical Properties of J-Joint Strength of Aa6351, Int. J. Eng. Sci., 2012, 1(1), p 1–5

M. Manikandan, N. Arivazhagan, M.N. Rao, and G.M. Reddy, Microstructure and Mechanical Properties of Alloy C-276 Weldments Fabricated by Continuous and Pulse Current Gas Tungsten Arc Welding Techniques, J. Manuf. Process., 2014, 16, p 563–572

K.D. Ramkumar, V. Joshi, S. Pandit, M. Agrawal, O.S. Kumar, S. Periwal, M. Manikandan, and N. Arivazhagan, Investigations on Microstructural and Mechanical Properties of Multi-pass Pulsed Current Gas Tungsten Arc Weldments of Monel 400 and Hastelloy C-276, Mater. Des., 2014, 64, p 775–782

P. Mithilesh, D. Varun, A. Reddy, P. Reddy, K.D. Ramkumar, N. Arivazhagan, and S. Narayanan, Investigations on Dissimilar Weldments of Inconel 625 and AISI, 304, Proced. Eng., 2014, 75, p 66–70

K.D. Ramkumar, S.V. Naren, V.R.K. Paga, A. Tiwari, and N. Arivazhagan, Development of Pulsed Current Gas Tungsten Arc Welding Technique for Dissimilar Joints of Marine Grade Alloys, J. Manuf. Process., 2016, 21, p 201–213

M. Arivarasu, D.R. Kasinath, and A. Natarajan, Effect of Continuous and Pulsed Current on the Metallurgical and Mechanical Properties of Gas Tungsten Arc Welded AISI, 4340 Aeronautical and AISI, 304L Austenitic Stainless Steel Dissimilar Joints, Mater. Res., 2015, 18(1), p 59–77

R. Neissi, M. Shamanian, and M. Hajihashemi, The Effect of Constant and Pulsed Current Gas Tungsten Arc Welding on Joint Properties of 2205 Duplex Stainless Steel to 316L Austenitic Stainless Steel, J. Mater. Eng. Perform., 2015, doi:10.1007/s1165-016-2033-4

V. Moura, A.Y. Kina, S.S.M. Tavares, L.D. Lima, and F.B. Mainier, Influence of Stabilization Heat Treatments on Microstructure, Hardness and Intergranular Corrosion Resistance of the AISI, 321 Stainless Steel, J. Mater. Sci., 2008, 43, p 536–540

P.K. Giridharan and N. Murugan, Optimisation of Pulsed GTA Welding Process Parameters for the Welding of AISI, 304L Stainless Steel Sheets, Int. J. Adv. Manuf. Tech., 2009, 40, p 478–489

ASTM E92–82, Standard Test Method for Vickers Hardness of Metallic Materials (West Conshohocken, PA, 2003)

ASTM E 8M-04, Standard Practice for Preparation Tension Testing of Metallic Materials (Philadelphia, PA, 2004)

ASTM E23-16B, Standard Test Method for Notched Bar Impact Test of Metallic Materials (ASTM International, West Conshohocken, PA, 2016)

M. Sireesha, V. Shankar, S.K. Albert, and S. Sundaresan, Microstructural Features of Dissimilar Welds Between 316LN Austenitic Stainless Steel and Alloy 800, Mat. Sci. Eng. A Struct., 2000, 292, p 74–82

H.S. Hosseini, M. Shamanian, and A. Kermanpur, Characterization of Microstructures and Mechanical Properties of Inconel 617/310 Stainless Steel Dissimilar Welds, Mater. Charact., 2011, 62, p 425–431

P. Sathiya, M.K. Mishra, R. Soundararajan, and B. Shanmugarajan, Shielding Gas Effect on Weld Characteristics in Arc-Augmented Laser Welding Process of Super Austenitic Stainless Steel, Opt. Laser Technol., 2013, 45, p 46–55

K.D. Ramkumar, S. Dev, V. Saxena, A. Chaudhary, N. Arivazhagan, and S. Narayanan, Effect of Flux Addition on the Microstructure and Tensile Strength of Dissimilar Weldments Involving Inconel 718 and AISI, 416, Mater. Des., 2015, 87, p 663–674

Acknowledgments

The authors are thankful to the Director, Dr. N. S. Chaudhari, VNIT Nagpur for providing the essential facilities to carry out this investigation and for his continuous support to publish current work. The authors express their gratitude to Mr. G.K. Banerjee and Mr. P. Singha for the provision of the welding facilities. The authors are also thankful to Mr. Shreedhar Gadge and Mrs. Varsha Patankar to help in carrying solution annealing and mechanical testing. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, S., Taiwade, R.V. & Vashishtha, H. Effect of Continuous and Pulsed Current Gas Tungsten Arc Welding on Dissimilar Weldments Between Hastelloy C-276/AISI 321 Austenitic Stainless Steel. J. of Materi Eng and Perform 26, 1146–1157 (2017). https://doi.org/10.1007/s11665-017-2570-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2570-5