Abstract

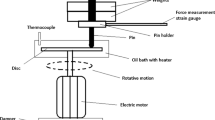

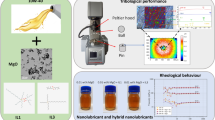

In various mechanical systems, lubricants are generally used to reduce friction and wear; thus, the total energy loss in the mechanical systems can be minimized by the proper enhancement of lubrication properties. In general, friction modifiers and antiwear additives are used to improve the tribological properties of the lubricant. However, the use of these additives has to be phased out due to their fast chemical degradation in their applications and other environmental issues. In recent years, the use of nanoparticles as a potential lubricant additive has received considerable attention because of its excellent mechanical and tribological characteristics. The present work describes the tribological behavior of nano-boric acid, multiwalled carbon nanotubes (MWCNTs), and functionalized multiwalled carbon nanotubes (FMWCNTs) modified with carboxylic acid. These nanoparticles were used to enhance the tribological properties of engine oil (SAE20W40) used to lubricate bronze alloy samples. The performance of these nano-coolants was assessed on a linear reciprocating ball-on-flat tribometer. Results highlight the friction and wear behavior of the nano-boric acid, MWCNTs, and FMWCNTs under three varying parameters such as the effect of nanoparticles concentration, load-carrying capacity, and sliding speed. The addition of nano-boric acid, MWCNTs, and FMWCNTs has significantly improved the tribological properties of the base lubricant. The addition of 0.5 wt.% of nano-boric acid, MWCNTs, and FMWCNTs to the base lubricant has decreased the coefficient of friction by 19.76, 30.55, and 35.65%, respectively, and a significant reduction in wear volume by 55.17, 71.42, and 88.97% was obtained in comparison with base lubricant.

Similar content being viewed by others

References

J.A.C. Cornelio, P.A. Cuervo, L.M. Hoyos-Palacio, J. Lara-Romero, and A. Toro, Tribological Properties of Carbon Nanotubes as Lubricant Additive in Oil and Water for a Wheel–Rail System, J. Mater. Res. Technol., 2016, 5(1), p 68–76

G. Cui, Q. Bi, J. Yang, and W. Liu, Fabrication and Study on Tribological Characteristics of Bronze–Alumina–Silver Composite Under Sea Water Condition, Mater. Des., 2013, 46, p 473–484

L. Liu, Z. Fang, A. Gu, and Z. Guo, Lubrication Effect of the Paraffin Oil Filled with Functionalized Multiwalled Carbon Nanotubes for Bismaleimide Resin, Tribol. Lett., 2011, 42, p 59–65

A. Mohamed, T.A. Osman, A. Khattab, and M. Zaki, Tribological Behavior of Carbon Nanotubes as an Additive on Lithium Grease, J. Tribol., 2015, 137, p 011801-1

A.K. Sharma, A.K. Tiwari, and A.R. Dixit, Rheological Behaviour of Nanofluids: A Review, Renew. Sustain. Energy Rev., 2016, 53, p 779

Y. Zhang, C. Li, D. Jia, D. Zhang, and X. Zhang, Experimental Evaluation of MoS2 Nanoparticles in Jet MQL Grinding with Different Types of Vegetable Oil as Base Oil, J. Clean. Prod., 2015, 87, p 930–940

P. Deshmukh, M. Lovell, W.G. Sawyer, and A. Mobley, On the Friction and Wear Performance of Boric Acid Lubricant Combinations in Extended Duration Operations, Wear, 2006, 260, p 1295–1304

H. Başa and Y.E. Karabacak, Investigation of the Effects of Boron Additives on the Performance of Engine Oil, Tribol. Trans., 2014, 57, p 740–748

M. Lovell, C.F. Higgs, P. Deshmukh, and A. Mobley, Increasing Formability in Sheet Metal Stamping Operations Using Environmentally Friendly Lubricants, J. Mater. Process. Technol., 2006, 177, p 87–90

W.G. Sawyer, J.C. Ziegert, T.L. Schmitz, and T. Barton, In Situ Lubrication with Boric Acid: Powder Delivery of an Environmentally Benign Solid Lubricant, Tribol. Trans., 2006, 49, p 284–290

N.R. Damera and V.K. Pasam, Performance Profiling of Boric Acid as Lubricant in Machining, J. Braz. Soc. Mech. Sci. Eng., 2008, 30, p 239

K.P. Rao, Y.V.R.K. Prasad, and C.L. Xie, Further Evaluation of Boric Acid Vis-a-vis Other Lubricants for Cold Forming Applications, Tribol. Int., 2011, 44, p 1118–1126

K.P. Rao and C.L. Xie, A Comparative Study on the Performance of Boric Acid with Several Conventional Lubricants in Metal Forming Processes, Tribol. Int., 2006, 39, p 663–668

P. Vamsi Krishna, R.R. Srikant, and D. Nageswara Rao, Experimental Investigation on the Performance of Nanoboric Acid Suspensions in SAE-40 and Coconut Oil During Turning of AISI, 1040 Steel, Int. J. Mach. Tools Manuf, 1040, 2010(50), p 911–916

D. Nageswara Rao and P. Vamsi Krishna, The Influence of Solid Lubricant Particle Size on Machining Parameters in Turning, Int. J. Mach. Tools Manuf., 2008, 48, p 107–111

M. Lovell, M.A. Kabir, P.L. Menezes, and C.F. Higgs, Influence of Boric Acid Additive Size on Green Lubricant Performance, Phil. Trans. R. Soc. A, 2010, 368, p 4851–4868

S. Shankar, G. Praveen Kumar, and P. Krishna Kumar, Experimental Study on Frictional Characteristics of Tungsten Carbide Versus Carbon as Mechanical Seals Under Dry and Eco-friendly Lubrications, Int. J. Refract. Metals Hard Mater., 2016, 54, p 39–45

X. Pei, L. Hu, W. Liu, and J. Hao, Synthesis of Water-Soluble Carbon Nanotubes via Surface Initiated Redox Polymerization and Their Tribological Properties as Water-Based Lubricant Additive, Eur. Polym. J., 2008, 44, p 2458–2464

B. Wang, X. Wang, W. Lou, and J. Hao, Rheological and Tribological Properties of Ionic Liquid-Based Nanofluids Containing Functionalized Multi-Walled Carbon Nanotubes, J. Phys. Chem. C, 2010, 114, p 8749–8754

H.F. Lu, B. Fei, J.H. Xin, R.H. Wang, L. Li, and W.C. Guan, Synthesis and Lubricating Performance of a Carbon Nanotube Seeded Miniemulsion, Carbon, 2007, 45, p 936–942

Y. Peng and Z. Ni, Tribological Properties of Stearic Acid Modified Multi-Walled Carbon Nanotubes in Water, J. Tribol., 2013, 135, p 012001

C.S. Chen, X.H. Chen, L.S. Xu, Z. Yang, and W.H. Li, Modification of Multi-walled Carbon Nanotubes with Fatty Acid and Their Tribological Properties as Lubricant Additive, Carbon, 2005, 43, p 1660–1666

D.-L. Cursaru, C. Andronescu, C. Pirvu, and R. Ripeanu, The Efficiency of Co-Based Single-Wall Carbon Nanotubes (SWNTs) as an AW/EP Additive for Mineral Base Oils, Wear, 2012, 290–291, p 133–139

L. Joly-Pottuz, F. Dassenoy, B. Vacher, J.M. Martin, and T. Mieno, Ultralow Friction and Wear Behaviour of Ni/Y-Based Single Wall Carbon Nanotubes (SWNTs), Tribol. Int., 2004, 37, p 1013–1018

ASTM Standard G 133-05: Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear, ASTM International, West Conshohocken, PA (2010).

F. Zhou, Y. Wang, W. Wu, T. Jing, S. Mei, and Y. Zhou, Synergetic Signal Amplification of Multi-walled Carbon Nanotubes-Fe3O4 Hybrid and Trimethyloctadecylammonium Bromide as a Highly Sensitive Detection Platform for Tetrabromobisphenol A, Sci. Rep., 2016, 6, p 38000

P. Nie, C. Min, X. Chen, C. Shen, W. Tu, and H. Song, Effect of MWCNTs-COOH Reinforcement on Tribological Behaviors of PI/MWCNTs-COOH Nanocomposites Under Seawater Lubrication, Tribol. Trans., 2016, 59(1), p 89–98

D.A. Constantine, Y. Wang, and E.J. Terrell, Effect of Reciprocation Frequency on Friction and Wear of Vibrating Contacts Lubricated with Soybean-Based B100 Biodiesel, Tribol. Lett., 2013, 50, p 279–285

S.P. Lonkar, O.S. Kushwaha, A. Leuteritz, G. Heinrich, and R.P. Singh, Self Photostabilizing UV-Durable MWCNT/Polymer Nanocomposites, RSC Adv., 2012, 2, p 12255–12262

X.M. Sui, S. Giordani, M. Prato, and H.D. Wagner, Effect of Carbon Nanotube Surface Modification on Dispersion and Structural Properties of Electrospun Fibers, Appl. Phys. Lett., 2009, 95, p 233113

N. Salah, M.S. Abdel-Wahab, A. Alshahrie, N.D. Alharbic, and Z.H. Khand, Carbon Nanotubes of Oil Fly Ash as Lubricant Additives for Different Base Oils and Their Tribology Performance, RSC Adv, 2017, 7, p 40295

S. Abbasi, S.M. Zebarjad, S.H.N. Baghban, A. Youssefi, and M.S.E. Kakhki, Experimental Investigation of the Rheological Behaviour and Viscosity of Decorated Multi-walled Carbon Nanotubes with TiO2 Nanoparticles/Water Nanofluids, J Therm Anal Calorim, 2016, 123, p 81–89

Y. Xia, L. Wang, X. Liu, and Y. Qiao, Tribological Properties of Phosphor Bronze and Nanocrystalline Nickel Coatings Under PAO + MoDTC and Ionic Liquid Lubricated Condition, Tribol. Lett., 2008, 31, p 149–158

P. Zhang, X. Liu, W. Lu, W. Zhai, M. Zhou, and J. Wang, Fretting Wear Behavior of CuNiAl Against 42CrMo4 Under Different Lubrication Conditions, Tribol. Int., 2018, 117, p 59–67

A.S. Subramanian, J.N. Tey, L. Zhang, B.H. NG, S. Roy, J. Wei, and X. Hu, Synergistic Bond Strengthening in Epoxy Adhesives Using Polydopamine/MWCNT Hybrids, Polymer, 2016, 82, p 285–294

X.H. Men, Z.Z. Zhang, H.J. Song, K. Wang, and W. Jiang, Functionalization of Carbon Nanotubes to Improve the Tribological Properties of Poly(furfuryl alcohol) Composite Coatings, Compos. Sci. Technol., 2008, 68, p 1042–1049

G. Cui, Q. Bi, S. Zhu, J. Yang, and W. Liu, Tribological Behavior of Cu–6Sn–6Zn–3Pb Under Sea Water, Distilled Water and Dry-Sliding Conditions, Tribol. Int., 2012, 55, p 126–134

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ajay Vardhaman, B.S., Amarnath, M., Ramkumar, J. et al. Experimental Investigations to Enhance the Tribological Performance of Engine Oil by Using Nano-Boric Acid and Functionalized Multiwalled Carbon Nanotubes: A Comparative Study to Assess Wear in Bronze Alloy. J. of Materi Eng and Perform 27, 2782–2795 (2018). https://doi.org/10.1007/s11665-018-3384-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3384-9