Abstract

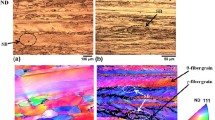

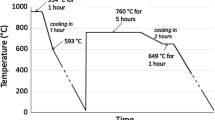

In the present investigation, a systematic study of the evolution of microstructure and crystallographic texture during hot deformation of Nb-1Zr-0.1C was carried out in the temperature range 1773-1973 K (1500-1700 °C) at different strain rates of 0.001, 0.01 and 0.1 s−1. The aim was to examine the mechanisms of dynamic recovery and recrystallization in a high-temperature range. A detailed microstructural analysis of the deformed samples was performed using the electron backscatter diffraction technique to study the occurrence and nature of various dynamic restoration processes; the different regimes of dynamic recovery and recrystallization were identified. The orientations of the dynamically recrystallized grains were found to be (001) <uvw>.

Similar content being viewed by others

References

R. Begley, D. Harrod, R. Gold, High Temperature Creep and Fracture Behavior of the Refractory Metals, in Refractory Metal Alloys Metallurgy and Technology. (Springer, 1968), pp. 41-83.

R. Buckman, Jr, and R. Begley, Development of High Strength Tantalum Base Alloys, Westinghouse Electric Corp, Pittsburgh, PA, 1970

J. Lemberg and R. Ritchie, Mo-Si-B Alloys for Ultrahigh-Temperature Structural Applications, Adv. Mater., 2012, 24(26), p 3445–3480

D. Mazey and C. English, Role of Refractory Metal Alloys in Fusion Reactor Applications, J. Less Common Met., 1984, 100, p 385–427

F. Ostermann, Controlling Carbide Dispersions in Niobium-Base Alloys, J. Less Common Met., 1971, 25(3), p 243–256

S. Primig et al., On the Recrystallization Behavior of Technically Pure Molybdenum, Int. J. Refract Met. Hard Mater., 2010, 28(6), p 703–708

V.S. Sarma et al., Recrystallisation Texture and Magnetisation Behaviour of Some FCC Ni-W Alloys, Scr. Mater., 2004, 50(7), p 953–957

J.H. Schneibel, E.J. Felderman, and E.K. Ohriner, Mechanical Properties of Ternary Molybdenum–Rhenium Alloys at Room Temperature and 1700 K, Scr. Mater., 2008, 59(2), p 131–134

Y. Tang and X. Guo, High Temperature Deformation Behavior of an Optimized Nb–Si Based Ultrahigh Temperature Alloy, Scr. Mater., 2016, 116, p 16–20

B. Lubarsky, L.I. Shure, Applications of Power Systems to Specific Missions, NASA Technical Report (Document ID:19670000948), 1966

T. Moss, R. Davies, and G. Barna, Refractory-Alloy Requirements for Space Power Systems, National Aeronautics and Space Administration, Cleveland, OH, 1970

R.H. Titran and M. Uz, Effects of Thermomechanical Processing on Tensile and Long-Time Creep Behavior of Nb-1% Zr-01% C Sheet, National Aeronautics and Space Administration, Cleveland, OH, 1994

R.L. Cummings, R.L. Davies, R.E. English, T.P. Moffitt, Potassium Rankine Systems Technology, NASA Technical Report (Document ID: 19670000946), 1966

G.P. Dix, S.S. Voss, Pied Piper: A Historical Overview of the US Space Power Reactor Program, in Space Nuclear Power Systems 1984: Proceedings, vol. 1 (1985)

L. Rosenblum, Liquid Metals for Aerospace Electric-Power Systems, JOM, 1963, 15(9), p 637–641

J. Semmel, Refractory Metals in Space Electric Power Conversion Systems, in Refractory Metal Alloys Metallurgy and Technology. (Springer, 1968), pp. 289-324

A. Korotayev et al., Nature of Secondary Phases and Mechanism of Rupture in a Niobium-Zirconium-Carbon Alloy, Phys. Met. Metall., 1981, 52(2), p 128–135

R.H. Titran, Long-Time Creep Behavior of Nb-1Zr Alloy Containing Carbon, NASA Technical Report (Document ID: 19870016784), 1986

R.H. Titran, Creep Strength of Niobium Alloys, Nb-1% Zr and PWC-11, National Aeronautics and Space Administration, Cleveland, OH, 1990

R.H. Titran, W.D. Klopp, Long-Time Creep Behavior of the Niobium Alloy C-103, NASA Technical Report (Report Number: NASA-TP-1727, E-224), 1980

R.H. Titran, T. Moore, T. Grobstein, Creep Properties of PWC-11 Base Metal and Weldments as Affected by Heat Treatment, NASA Technical Report (Report Number: NASA-TP-1727, E-224), 1986

R.H. Titran, M. Uz, Effects of Thermomechanical Processing on the Microstructure and Mechanical Properties of Nb-1Zr-C Alloys, NASA Technical Report (Report Number: NASA-TM-107207, NAS 1.15:107207, E-10220), 1996

Uz, M. and R. Titran, Effects of Processing and Prolonged High Temperature Exposure on the Microstructure of Nb-1Zr-C Sheet. MRS Online Proc. Libr. Arch. 322 (1993).

M. Uz, R.H. Titran, Thermal Stability of the Microstructure of an Aged Nb-Zr-C Alloy, in AIP Conference Proceedings (AIP, 1991)

I. Dulera and R. Sinha, High Temperature Reactors, J. Nucl. Mater., 2008, 383(1–2), p 183–188

D. Farkas and A. Mukherjee, Creep Behavior and Microstructural Correlation of a Particle-Strengthened Nb-1Zr-0.1C Alloy, J. Mater. Res., 1996, 11(9), p 2198–2205

D. Farkas and A. Mukherjee, Stress Cycle Testing During Creep of a Particle-Strengthened Nb-1Zr-0.1C Alloy, Mater. Sci. Eng. A, 1997, 1(222), p 21–27

B. Vishwanadh et al., Development of Nb-1% Zr-0.1% C Alloy as Structural Components for High Temperature Reactors, J. Nucl. Mater., 2012, 427(1–3), p 350–358

A. Chaudhuri et al., Microstructural Features of Hot Deformed Nb-1Zr-0.1C Alloy, JOM, 2014, 66(9), p 1923–1929

A. Sarkar et al., Hot Deformation Behavior of Nb-1Zr-0.1C Alloy in the Temperature Range 700-1700 °C, J. Nucl. Mater., 2012, 422(1–3), p 1–7

J. Chakravartty, et al. Dynamic Recrystallization in Zirconium Alloys, in Zirconium in the Nuclear Industry: 16th International Symposium. (ASTM International, 2012)

A. Marchattiwar et al., Dynamic Recrystallization During Hot Deformation of 304 Austenitic Stainless Steel, J. Mater. Eng. Perform., 2013, 22(8), p 2168–2175

A. Sarkar et al., Creep Behavior of Hydrogenated Zirconium Alloys, J. Mater. Eng. Perform., 2014, 23(10), p 3649–3656

A. Sarkar and J. Chakravartty, Hot Deformation Behavior of Zr-1Nb Alloy: Characterization by Processing Map, J. Nucl. Mater., 2013, 440(1), p 136–142

A. Sarkar et al., Kinetics of Dynamic Recrystallization in Cobalt: A Study Using the Avrami Relation, Physica Status Solidi (A), 2011, 208(4), p 814–818

A. Sarkar, J. Chakravartty, and I. Samajdar, The Avrami Kinetics of Dynamic Recrystallization in Cadmium, Metall. Mater. Trans. A, 2010, 41(10), p 2466–2470

A. Sarkar et al., Kinetics of Dynamic Recrystallization in Ti-Modified 15Cr-15Ni-2Mo Austenitic Stainless Steel, J. Nucl. Mater., 2013, 432(1–3), p 9–15

T. Sakai and J.J. Jonas, Overview no. 35 Dynamic Recrystallization: Mechanical and Microstructural Considerations, Acta Metall., 1984, 32(2), p 189–209

A. Chaudhuri et al., Hot Deformation Behaviour of Mo-TZM and Understanding the Restoration Processes Involved, Acta Mater., 2019, 164, p 153–164

A. Chaudhuri, A. Sarkar, and S. Suwas, Investigation of Stress–Strain Response, Microstructure and Texture of Hot Deformed Pure Molybdenum, Int. J. Refract Metal. Hard Mater., 2018, 73, p 168–182

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, Elsevier, Amsterdam, 2012

W.P. Sun and E.B. Hawbolt, Comparison Between Static and Metadynamic Recrystallization-an Application to the Hot Rolling of Steels, ISIJ Int, 1997, 37(10), p 1000–1009

R.M. Ahmadabadi et al., Dynamic Recrystallization Behavior of AISI, 422 Stainless Steel During Hot Deformation Processes, J. Mater. Eng. Perform., 2018, 27(2), p 560–571

S. Du, S. Chen, and J. Song, Dynamic Recrystallization Kinetics and Microstructural Evolution for LZ50 Steel During Hot Deformation, J. Mater. Eng. Perform., 2016, 25(9), p 3646–3655

S. He et al., Effect of Deformation Temperature on Dynamic Recrystallization and CSL Grain Boundary Distribution of Fe-36% Ni Invar Alloy, J. Mater. Eng. Perform., 2018, 27, p 2759–2765

Z. Huang et al., Dynamic Recrystallization Behavior and Texture Evolution of NiAl Intermetallic During Hot Deformation, J. Mater. Eng. Perform., 2017, 26(5), p 2377–2387

R. Kapoor, G.B. Reddy, and A. Sarkar, Discontinuous Dynamic Recrystallization in α-Zr, Mater. Sci. Eng. A, 2018, 718, p 104–110

Y. Lin et al., EBSD Analysis of Evolution of Dynamic Recrystallization Grains and δ Phase in a Nickel-Based Superalloy During Hot Compressive Deformation, Mater. Des., 2016, 97, p 13–24

Y. Lin et al., New Constitutive Model for Hot Deformation Behaviors of Ni-Based Superalloy Considering the Effects of Initial δ Phase, J. Mater. Eng. Perform., 2015, 24(9), p 3527–3538

Y. Lin and X.-Y. Wu, A New Method for Controlling Billet Temperature During Isothermal Die Forging of a Complex Superalloy Casing, J. Mater. Eng. Perform., 2015, 24(9), p 3549–3557

F. Pilehva et al., Hot Deformation and Dynamic Recrystallization of Ti-6Al-7Nb Biomedical Alloy in Single-Phase β Region, J. Mater. Eng. Perform., 2015, 24(5), p 1799–1808

P.S. Roodposhti et al., Effects of Microstructure and Processing Methods on Creep Behavior of AZ91 Magnesium Alloy, J. Mater. Eng. Perform., 2016, 25(9), p 3697–3709

A. Sarkar et al., High Temperature Deformation Behavior of Zr-1Nb Alloy, J. Alloys Compd., 2017, 703, p 56–66

B. Wang et al., Dynamic Recrystallization Mechanism of Inconel 690 Superalloy During Hot Deformation at High Strain Rate, J. Mater. Eng. Perform., 2013, 22(8), p 2382–2388

D. Hull and D.J. Bacon, Introduction to Dislocations, Butterworth-Heinemann, Oxford, 2001

J.P. Hirth, J. Lothe, Theory of Dislocations, 2nd ed., Wiley, New York, 1982

B. Verlinden et al., Thermo-Mechanical Processing of Metallic Materials, Vol 11, Elsevier, Amsterdam, 2007

A. Behera et al., Hot Deformation Behaviour of Niobium in Temperature Range 700-1500°, C. Materials Science and Technology, 2014, 30(6), p 637–644

F. Humphreys, Review Grain and Subgrain Characterisation by Electron Backscatter Diffraction, J. Mater. Sci., 2001, 36(16), p 3833–3854

S. Mitsche, P. Pölt, and C. Sommitsch, Recrystallization Behaviour of the Nickel-Based Alloy 80 A During Hot Forming, J. Microsc., 2007, 227(3), p 267–274

S. Mitsche et al., Quantification of the Recrystallized Fraction in a Nickelbase-Alloy from EBSD-Data, Microsc. Microanal., 2003, 9(S03), p 344–345

J. Tarasiuk, P. Gerber, and B. Bacroix, Estimation of Recrystallized Volume Fraction from EBSD Data, Acta Mater., 2002, 50(6), p 1467–1477

S. Wright, Quantification of Recrystallized Fraction from Orientation Imaging Scans, ICOTOM 12 in Proceedings of the 12th International Conference on Textures of Materials (ICOTOM 12), Montreal, Canada, J.A. Szpunar, Ed., NRC Research Press, Ottawa, 1999,

N.P. Gurao et al., Evolution of Crystallographic Texture and Microstructure During Cold Rolling of Twinning-Induced Plasticity (TWIP) Steel: Experiments and Simulations, Metall. Mater. Trans. A, 2012, 43(13), p 5193–5201

R. Kapoor et al., Softening of Al During Multi-axial Forging in a Channel Die, Mater. Sci. Eng. A, 2013, 560, p 404–412

Y. Zhong et al., Dislocation Structure Evolution and Characterization in the Compression Deformed Mn-Cu Alloy, Acta Mater., 2007, 55(8), p 2747–2756

S. Biswas et al., Evolution of Texture and Microstructure During Hot Torsion of a Magnesium Alloy, Acta Mater., 2013, 61(14), p 5263–5277

S. Biswas, S.S. Dhinwal, and S. Suwas, Room-Temperature Equal Channel Angular Extrusion of Pure Magnesium, Acta Mater., 2010, 58(9), p 3247–3261

S. Biswas and S. Suwas, Evolution of Sub-micron Grain Size and Weak Texture in Magnesium Alloy Mg-3Al-0.4 Mn by a Modified Multi-axial Forging Process, Scr. Mater., 2012, 66(2), p 89–92

W. Aretz, D. Ponge, and G. Gottstein, Evolution of Necklace Structures During Hot Compression of Ni3Al+ B, Scr. Metall. Mater., 1992, 27(11), p 1593–1598

M. Drury and F. Humphreys, The Development of Microstructure in Al-5% Mg During High Temperature Deformation, Acta Metall., 1986, 34(11), p 2259–2271

Acknowledgments

The authors are grateful to the Board of Research in Nuclear Sciences, Department of Atomic Energy, Government of India (Grant No. RP-ON 2011/36/19), for financial support for the experimental expenses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chaudhuri, A., Sarkar, A., Kapoor, R. et al. Understanding the Mechanism of Dynamic Recrystallization During High-Temperature Deformation in Nb-1Zr-0.1C Alloy. J. of Materi Eng and Perform 28, 448–462 (2019). https://doi.org/10.1007/s11665-018-3799-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3799-3