Abstract

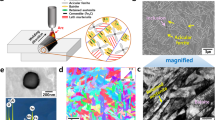

Hypereutectoid SAE 52100 steel is extensively used in bearing applications. Microstructure modification in terms of dislocation martensite and carbide refinement was achieved for SAE 52100 steel through a simple duplex heat treatment. Refinement of prior austenite grains to less than 5 μm resulted in the conversion of conventional high-carbon twinned martensite to dislocation martensite. The concurrent refinement of austenite grains and carbide precipitates was accomplished by high-temperature austenitization followed by low-temperature tempering. This resulted in nanoscale nonstoichiometric ε-carbides within a heavily twinned martensitic structure. These nanoscale carbides acted as grain boundary pinning agents after their transformation to θ-carbides during the final austenitization process. The resulting microstructure was characterized by a fine dispersion of θ-carbides within dislocation martensite and showed roughly 24% increase in tensile strength and 30% better wear resistance compared to conventional structure.

Similar content being viewed by others

References

H.K.D.H. Bhadeshia, Steels for Bearings, Prog. Mater Sci., 2012, 57(2), p 268–435

J. Chakraborty, P.P. Chattopadhyay, D. Bhattacharjee, and I. Manna, Microstructural Refinement of Bainite and Martensite for Enhanced Strength and Toughness in High-Carbon Low-Alloy Steel, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2010, 41(11), p 2871–2879

G.E. Totten, Steel Heat Treatment, Taylor & Francis Group, Boca Raton, 2006, p 820

Y. Wang, F. Zhang, Z. Yang, B. Lv, and C. Zheng, Rolling Contact Fatigue Performances of Carburized And High-C Nanostructured Bainitic Steels, Materials (Basel), 2016, 9(12), p 1–12

F. Khodabakhshi, M. Haghshenas, and B. Koohbor, Hardness–Strength Relationships in Fine and Ultra-Fine Grained Metals Processed Through Constrained Groove Pressing, Mater. Sci. Eng. A, 2015, 636, p 331–339

T.T. Huang, R.B. Gou, W.J. Dan, and W.G. Zhang, Strain-Hardening Behaviors of Dual Phase Steels with Microstructure Features, Mater. Sci. Eng. A, 2016, 672(672), p 88–97

J. Zhang, H. Di, Y. Deng, and R.D.K. Misra, Effect of Martensite Morphology and Volume Fraction on Strain Hardening and Fracture Behavior of Martensite–Ferrite Dual Phase Steel, Mater. Sci. Eng. A, 2015, 627, p 230–240

M. Calcagnotto, Y. Adachi, D. Ponge, and D. Raabe, Deformation and Fracture Mechanisms in Fine- and Ultrafine-Grained Ferrite/Martensite Dual-Phase Steels and the Effect of Aging, Acta Mater., 2011, 59(2), p 658–670

C.A. Stickels, Carbide Refining Heat Treatments for 52100 Bearing Steel, Metall. Trans., 1974, 5(4), p 865–874

R.J. Kar, R.M. Horn, and V.F. Zackay, The Effect of Heat Treatment on Microstructure and Mechanical Properties in 52100 Steel, Metall. Trans. A, 1979, 10(November), p 1711–1717

N. Luzginova, L. Zhao, and J. Sietsma, Evolution and Thermal Stability of Retained Austenite in SAE 52100 Bainitic Steel, Mater. Sci. Eng. A, 2007, 448(1–2), p 104–110

A.T.W. Barrow, J.H. Kang, and P.E.J. Rivera-Díaz-Del-Castillo, The → η → θ Transition in 100Cr6 and Its Effect on Mechanical Properties, Acta Mater., 2012, 60(6–7), p 2805–2815

J.J. Sun, Y.N. Liu, Y.T. Zhu, F.L. Lian, H.J. Liu, T. Jiang, S.W. Guo, W.Q. Liu, and X.B. Ren, Super-Strong Dislocation-Structured High-Carbon Martensite Steel, Sci. Rep., 2017, 7(1), p 1–7

N.V. Luzginova, L. Zhao, and J. Sietsma, The Cementite Spheroidization Process in High-Carbon Steels with Different Chromium Contents, Metall. Mater. Trans., 2008, 39, p 513–521

Y. Lu, H. Yu, and R.D. Sisson, The Effect of Carbon Content on the c/a Ratio of As-Quenched Martensite in Fe–C Alloys, Mater. Sci. Eng. A, 2017, 700(April), p 592–597

D.E. Jiang and E.A. Carter, Carbon Dissolution and Diffusion in Ferrite and Austenite from First Principles, Phys. Rev. B Condens. Matter Mater. Phys., 2003, 67(21), p 1–11

R. Hossain, F. Pahlevani, M.Z. Quadir, and V. Sahajwalla, Stability of Retained Austenite in High Carbon Steel Under Compressive Stress: An Investigation from Macro to Nano Scale, Sci. Rep., 2016, 6(October), p 1–11

X. Qiao, L. Han, W. Zhang, and J. Gu, Thermal Stability of Retained Austenite in High-Carbon Steels During Cryogenic and Tempering Treatments, ISIJ Int., 2016, 56(1), p 140–147

J.M. Beswick, The Effect of Chromium in High Carbon Bearing Steels, Metall. Mater. Trans. A, 1987, 18, p 1897–1906

S. Ghosh, S. Mula, and D. Kumar Mondal, Development of Ultrahigh Strength Cast-Grade Microalloyed Steel by Simple Innovative Heat Treatment Techniques for Industrial Applications, Mater. Sci. Eng. A, 2017, 700, p 67–680

X.T. Deng, T.L. Fu, Z.D. Wang, R.D.K. Misra, and G.D. Wang, Epsilon Carbide Precipitation and Wear Behaviour of Low Alloy Wear Resistant Steels, Mater. Sci. Technol. (United Kingdom), 2016, 32(4), p 320–327

W. Song, J. Von Appen, P. Choi, R. Dronskowski, D. Raabe, and W. Bleck, Atomic-Scale Investigation of ε and θ Precipitates in Bainite in 100Cr6 Bearing Steel by Atom Probe Tomography and Ab Initio Calculations, Acta Mater., 2013, 61(20), p 7582–7590

A.T.W. Barrow and P.E.J. Rivera-Díaz-Del-Castillo, Nanoprecipitation in Bearing Steels, Acta Mater., 2011, 59(19), p 7155–7167

J. Weissmüller, Alloy Effects in Nanostructures, Nanostruct. Mater., 1993, 3(1–6), p 261–272

C.H. Young and H.K.D.H. Bhadeshia, Strength of Mixtures of Bainite and Martensite, Mater. Sci. Technol., 1994, 10(3), p 209–214

S. Queyreau, G. Monnet, and B. Devincre, Orowan Strengthening and Forest Hardening Superposition Examined by Dislocation Dynamics Simulations, Acta Mater., 2010, 58(17), p 5586–5595

Acknowledgments

The authors thank the Materials Research Facility at University of North Texas for access to the characterization equipment used in this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Data Availability

All the raw/processed data obtained in this study are available upon request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salloom, R., Ayyagari, A.V. & Mukherjee, S. Nanoengineered Hypereutectoid Steel with Superior Hardness and Wear Resistance. J. of Materi Eng and Perform 28, 2202–2211 (2019). https://doi.org/10.1007/s11665-019-03995-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03995-3