Abstract

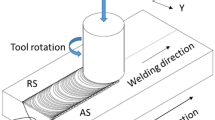

The susceptibility of API-X70 friction stir weld zones to corrosion in a Na2SO4 acid medium is successfully investigated using an innovative microcell setup. Microstructures were characterized by optical and electron microscopy, Vickers microhardness mapping and linear potential scan voltammetry, at micro- and macroscales. Potential galvanic couples between the weld zones were identified. The most anodic zone was base metal, which, with a banded microstructure of ferrite and perlite, developed a potential difference of up to 45 mV in comparison with the adjacent heat-affected zone. Friction stir welding promoted solute redistribution and the formation of martensite/retained austenite constituent, which contributed to reduced galvanic corrosion between ferrite and cementite. The thermo-mechanically affected zone was the most cathodic region, composed of acicular ferrite, coarse bainite and martensite/retained austenite constituent. Polarization resistance progressively increased, and corrosion current density progressively decreased, from base metal toward stir zone. In addition to the reduction in galvanic corrosion, a more uniform distribution of corrosion products in the stir zone also accounted for this behavior.

Similar content being viewed by others

References

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng., R, 2005, 50(1-2), p 1–78

G.K. Padhy, C.S. Wu, and S. Gao, Friction Stir Based Welding and Processing Technologies: Processes, Parameters, Microstructures and Applications—A Review, J. Mater. Sci. Technol., 2018, 34(1), p 1–38

B.Y.J. Defalco and R. Steel, Friction Stir Process Now Welds Steel Pipe, Weld. J., 2009, 5, p 44–48

T.F.A. Santos, T.F.C. Hermenegildo, C.R.M. Afonso, R.R. Marinho, M.T.P. Paes, and A.J. Ramirez, Fracture Toughness of ISO 3183 X80M (API, 5L X80) Steel Friction Stir Welds, Eng. Fract. Mech., 2010, 77(15), p 937–2945

T.W. Nelson and S.A. Rose, Controlling Hard Zone Formation in Friction Stir Processed HSLA Steel, J. Mater. Process. Technol., 2016, 231, p 66–74

J.W. Sowards, T. Gnaupel-Herold, J.D. McColskey, V.F. Pereira, and A.J. Ramirez, Characterization of Mechanical Properties, Fatigue-Crack Propagation, and Residual Stress in a Microalloyed Pipeline-Steel Friction Stir Weld, Mater. Des., 2015, 88, p 632–642

J.A. Avila, J. Rodriguez, P.R. Mei, and A.J. Ramirez, Microstructure and Fracture Toughness of Multipass Friction Stir Welded Joints of API, 5L-X80 Steel Plates, Mater. Sci. Eng. A, 2016, 673, p 257–265

P.S. Pao, R.W. Fonda, H.N. Jones, C.R. Feng, and D.W. Moon, Friction Stir Welding of HSLA-65 Steel, Friction Stir Welding and Processing IV, R.S. Mishra, M.W. Mahoney, T.J. Lienert, and K.V. Jata (Eds.), February 25–March 1, 2007 (Orlando), The Minerals, Metals & Materials Society, John Wiley & Sons, 2007, p 243–251

R.S. Mishra, P.S. De, and N. Kumar, Friction Stir Welding and Processing: Science and Engineering, Springer, Berlin, 2014

K.D. Ralston, N. Birbilis, and C.H.J. Davies, Revealing the Relationship Between Grain Size and Corrosion Rate of Metals, Scr. Mater., 2010, 63(12), p 1201–1204

D.K. Jangir, A. Verma, K.M. Sankar, A.S. Khanna, and A. Singla, Influence of Grain Size on Corrosion Resistance and Electrochemical Behavior of Mild Steel, Int. J. Res. Appl. Sci. Eng. Technol., 2018, 6(4), p 2875–2881

S. Gollapudi, Grain Size Distribution Effects on the Corrosion Behaviour of Materials, Corros. Sci., 2012, 62, p 90–94

H.B. Li, Z.H. Jiang, H. Feng, S.C. Zhang, L. Li, P.D. Han, R.D.K. Misra, and J.Z. Li, Microstructure, Mechanical and Corrosion Properties of Friction Stir Welded High Nitrogen Nickel-Free Austenitic Stainless Steel, Mater. Des., 2015, 84, p 291–299

M. Jariyaboon, A.J. Davenport, R. Ambat, B.J. Connolly, S.W. Williams, and D.A. Price, The Effect of Welding Parameters on the Corrosion Behaviour of Friction Stir Welded AA2024T351, Corros. Sci., 2007, 49(2), p 877–909

Z.Y. Liu, C.W. Du, C. Li, F.M. Wang, and X.G. Li, Stress Corrosion Cracking of Welded API, X70 Pipeline Steel in Simulated Underground Water, J. Mater. Eng. Perform., 2013, 22(9), p 2550–2556

G.A. Zhang and Y.F. Cheng, Micro-Electrochemical Characterization of Corrosion of Welded X70 Pipeline Steel in Near-Neutral pH Solution, Corros. Sci., 2009, 51(8), p 1714–1724

J.R. Davis, Corrosion of Carbon Steel and Low-Alloy Steel Weldments, Corrosion of Weldments, ASM International, Cleveland, 2006, p 13–41

P.J. Konkol, J.A. Mathers, R. Johnson, and J.R. Pickens, Friction Stir Welding of HSLA-65 Steel for Shipbuilding, J. Ship Prod. Des., 2003, 19(3), p 159–164

D. Trinh, S. Frappart, G. Rückert, F. Cortial, and S. Touzain, Effect of Friction Stir Welding Process on Microstructural Characteristics and Corrosion Properties of Steels for Naval Applications, Corros. Eng. Sci. Technol., 2019, 54(4), p 353–361

G.J. Abraham, V. Kain, G.K. Dey, and V.S. Raja, Corrosion Characterisation of Laser Beam and Tungsten Inert Gas Weldment of Nickel Base Alloys: Micro-Cell Technique, Corros. Sci., 2015, 93, p 1–8

H. Böhni, T. Suter, and A. Schreyer, Microtechniques and Nanotechniques to Study Localized Corrosion, Electrochim. Acta, 1995, 40(10), p 1361–1368

T. Suter and H. Böhni, A New Microelectrochemical Method to Study Pit Initiation on Stainless Steels, Electrochim. Acta, 1997, 42(20–22), p 3275–3280

F. Andreatta and L. Fedrizzi, The Use of the Electrochemical Micro-Cell for the Investigation of Corrosion Phenomena, Electrochim. Acta, 2016, 203, p 337–349

T. Suter and H. Bohni, Microelectrodes for Corrosion Studies in Microsystems, Electrochim. Acta, 2001, 47, p 191–199

H. Li, S. Yang, S. Zhang, B. Zhang, Z. Jiang, H. Feng, P. Han, and J. Li, Microstructure Evolution and Mechanical Properties of Friction Stir Welding Super-Austenitic Stainless Steel S32654, Mater. Des., 2017, 118, p 207–217

I.A. Pasti and T. Lazarevic, Switching Between Voltammetry and Potentiometry in Order to Determine H + or OH Ion Concentration over the Entire pH Scale by Means of Tungsten Disk Electrode, J. Electroanal. Chem., 2012, 665, p 83–89

S. Kou, Welding Metallurgy, 2nd ed., Wiley, Hoboken, 2003

H. Aydin and T.W. Nelson, Microstructure and Mechanical Properties of Hard Zone in Friction Stir Welded X80 Pipeline Steel Relative to Different Heat Input, Mater. Sci. Eng. A, 2013, 586, p 313–322

S.H. Mousavi Anijdan, D. Sediako, and S. Yue, Optimization of Flow Stress in Cool Deformed Nb-Microalloyed Steel by Combining Strain Induced Transformation of Retained Austenite, Cooling Rate and Heat Treatment, Acta Mater., 2012, 60(3), p 1221–1229

A. Tribe and T.W. Nelson, Study on the Fracture Toughness of Friction Stir Welded API, X80, Eng. Fract. Mech., 2015, 150, p 58–69

S.H. Mousavi Anijdan and S. Yue, The Effect of Cooling Rate, and Cool Deformation Through Strain-Induced Transformation, on Microstructural Evolution and Mechanical Properties of Microalloyed Steels, Metall. Mater. Trans. A, 2012, 43(4), p 1140–1162

M. Ferhat, A. Benchettara, S.E. Amara, and D. Najjar, Corrosion Behaviour of Fe-C Alloys in a Sulfuric Medium, J. Mater. Environ. Sci., 2014, 5(4), p 1059–1068

R.O. Ritchie, M.H.C. Cedeno, V.F. Zackay, and E.R. Parker, Effects of Silicon Additions and Retained Austenite on Stress Corrosion Cracking in Ultrahigh Strength Steels, Metall. Trans. A, 1978, 9(1), p 35–40

C.W. Du, X.G. Li, P. Liang, Z.Y. Liu, G.F. Jia, and Y.F. Cheng, Effects of Microstructure on Corrosion of X70 Pipe Steel in an Alkaline Soil, J. Mater. Eng. Perform., 2008, 18(2), p 216–220

N. Ochoa, C. Vega, N. Pébère, J. Lacaze, and J.L. Brito, CO2 Corrosion Resistance of Carbon Steel in Relation with Microstructure Changes, Mater. Chem. Phys., 2015, 156, p 198–205

M. Alizadeh and S. Bordbar, The Influence of Microstructure on the Protective Properties of the Corrosion Product Layer Generated on the Welded API, X70 steel in Chloride Solution, Corros. Sci., 2013, 70, p 170–179

C.T. Kwok, H.C. Man, and F.T. Cheng, Cavitation Erosion and Pitting Corrosion Behaviour of Laser Surface-Melted Martensitic Stainless Steel UNS S42000, Surf. Coat. Technol., 2000, 126, p 238–255

X. Hao, J. Dong, I.-I.N. Etim, J. Wei, and W. Ke, Sustained Effect of Remaining Cementite on the Corrosion Behavior of Ferrite-Pearlite Steel Under the Simulated Bottom Plate Environment of Cargo Oil Tank, Corros. Sci., 2016, 110, p 296–304

K.D. Ralston, D. Fabijanic, and N. Birbilis, Electrochimica Acta Effect of Grain Size on Corrosion of High Purity Aluminium, Electrochim. Acta, 2011, 56(4), p 1729–1736

F. Arjmand and A. Adriaens, Microcapillary Electrochemical Droplet Cells: Applications in Solid-State Surface Analysis, J. Solid State Electrochem., 2014, 18(7), p 1779–1788

F. Arjmand and A. Adriaens, Investigation of 304L Stainless Steel in a NaCl Solution Using a Microcapillary Electrochemical Droplet Cell: Comparison with Conventional Electrochemical Techniques, Electrochim. Acta, 2012, 59, p 222–227

R. Oltra, B. Vuillemin, F. Thebault, and F. Rechou, Effect of the Surrounding Aeration on Microcapillary Electrochemical Cell Experiments, Electrochem. Commun., 2008, 10(6), p 848–850

Acknowledgments

The authors would like to thank Dr. Getúlio de Vasconcelos and MSc. Renê Volu, from Dedalo Laboratory at the Institute for Advanced Studies (IEAv), for their support with laser processing; CAPES, for graduation scholarship; and FAPESP, for research funding (Proc. 2016/10637-4).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

da Cruz, J.R., Bertazzoli, R. Characterization of Corrosion Within Friction Stir Weld Zones of an API X-70 Steel Using a Novel Microcell Setup. J. of Materi Eng and Perform 29, 98–108 (2020). https://doi.org/10.1007/s11665-019-04531-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04531-z