Abstract

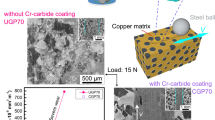

The present work evaluates the coefficient of friction (CoF), electrical resistivity, and electrical contact resistance (ECR) of the electrodeposited single-layered Cu-SiC nanocomposite coating and five-layered Cu, Cu-SiC functionally graded coating (FGC). Both the coatings have a similar thickness (60 µm) and same composition at the top surface (7 vol.% reinforced SiC nanoparticles), while the FGC has a gradient of composition and microstructure throughout the thickness. The Cu, Cu-SiC FGC has two layers of Cu-SiC with a decrement in the content of SiC nanoparticles from 7 to 2 vol.% followed by three Cu layers with an increasing crystallite size towards the substrate. The electrical resistivity of the Cu, Cu-SiC FGC is measured by the four-wire resistance measurement method and the value is observed to be 50% less than the conventional nanocomposite coating. A linear reciprocating sliding wear test is carried out at 2, 5 and 8 N load at a constant frequency and stroke length of 10 Hz and 2 mm, respectively. The monitored value of CoF is significantly less for the Cu, Cu-SiC FGC than the single-layered coating at 2 and 5 N loads and is nearly equal at 8 N load. It is observed that before wear, the ECR values of both the coatings are higher than the uncoated Cu and after wear the ECR value of Cu, Cu-SiC FGC is the lowest.

Similar content being viewed by others

References

P.G. Slade, Electrical Contacts: Principles and Applications, second, CRC Press, Taylor & Francisgroup, 2013

S. Hannel, S. Fouvry, P. Kapsa, and L. Vincent, The Fretting Sliding Transition as a Criterion for Electrical Contact Performance, Wear, 2001, 249, p 761–770

P. Jedrzejczyk, S. Fouvry, and P. Chalandon, A Fast Methodology to Quantify Electrical-Contact Behaviour Under Fretting Loading Conditions, Wear, 2009, 267, p 1731–1740

Anon, Materials evaluation under fretting conditions, ASTM International, 1982, STP780–EB ed. WestConshohocken, PA

S. Fouvry and P. Kapsa, Surface damage under reciprocating sliding, Fundamentals of Tribology and Bridging the Gap Between the Macro- and Micro/Nanoscales, B. Bhushan, Ed., Springer, Dordrecht, 2001, p 377–391

G.X. Chen and Z.R. Zhou, Study on Transition Between Fretting and Reciprocating Sliding Wear, Wear, 2001, 250–251, p 665–672

Y. Tamai, Low Friction of Metals in Reciprocating Sliding, J. Appl. Phys., 1874, 1959(32), p 1437–1440

D. Chapman, H.W. Turner, C. Turner, Copper in Electrical Contacts, Copp Dev Assoc 2015, 223

S. Timsit, Electrical Contact Resistance: Properties of Stationary Interfaces. in Electrical Contacts Proceedings of the Forty-Fourth IEEE Holm Conference on Electrical Contacts (Cat. No. 98CB36238), 1998, Arlington, VA, USA, p 1-19

B. Andre, Nanocomposites for use in sliding electrical contacts, Acta Universitatis Upsaliensis Uppsala, Sweden, 2011

Y. Zhan and G. Zhang, The Effect of Interfacial Modifying on the Mechanical and Wear Properties of SiCp/Cu Composites, Mater. Lett., 2003, 57, p 4583–4591

H. Singh, L. Kumar, S.N. Alam, Development of Cu reinforced sic particulate composites, IOP Conf Ser Mater Sci Eng, 2015, 75

R.N. Ahmed, C.S. Ramesh, Tribological properties of cast copper-SiC-Graphite hybrid composites, in International Symposium Research Materials Science Engineering India, 2004, p 20–22

G.F.C. Efe, M. Ipek, S. Zeytin, and C. Bindal, Fabrication and Properties of sic Reinforced Copper-Matrix-Composite Contact Material, Mater. Technol., 2016, 50, p 585–590

R. Zhang, L. Gao, Y. Pan, L. Chen, and J. Guo, Preparation of Cu/SiC FGM by Coating Method and SPS Sintering, Mater. Sci. Forum, 2003, 423–425, p 249–252

S.G. Shiri, P. Abachi, K. Pourazarang, and M.M. Rahvard, Preparation of In Situ Cu/NbC Nanocomposite and its Functionally Graded Behavior for Electrical Contact Applications, Trans. Nonferrous Met. Soc. China, 2015, 25, p 863–872

A. Raheem and K.A. Ali, Preparation and Mechanical Characterization of Cu-Al2O3 Functionally Graded Material for Electrical Contact Applications, J. Univ. Babylon, 2017, 25, p 1339–1351

A.K. Pradhan and S. Das, Pulse Reverse Electrodeposition of Cu-SiC Nanocomposite Coating: Effects of Surfactants and Deposition Parameters, Metall. Mater. Trans. A, 2014, 45, p 5708–5720

A.K. Pradhan and S. Das, Pulse-Reverse Electrodeposition of Cu-SiC Nanocomposite Coating: Effect of Concentration of SiC in the Electrolyte, J. Alloys Compd., 2014, 590, p 294–302

S. Das, S. Banthia, A. Patra, S. Sengupta, and S.B. Singh, Novel Bilayer Zn-Ni/Ni-Co-SiC Nanocomposite Coating with Exceptional Corrosion and Wear Properties by Pulse Electrodeposition, J. Alloys Compd., 2018, 738, p 394–404

A. Mitra, M. Mallik, S. Sengupta, S. Banthia, S. Das, and K. Das, Effect of Anodic Passivation at High Applied Potential Difference on the Crystal Shape and Morphology of Copper Electrodeposits: Thermodynamics and Kinetics of Electrocrystallization, Cryst. Growth Des., 2017, 17(4), p 1539–1549

S. Banthia, S. Sengupta, M. Mallik, S. Das, and K. Das, Substrate Effect on Electrodeposited Copper Morphology and Crystal Shapes, Surf. Eng., 2018, 34, p 482–495

A.K. Pradhan and S. Das, Dry Sliding Wear and Friction Behavior of Cu-SiC Nanocomposite Coating Prepared by Pulse Reverse Electrodeposition, Tribol. Trans., 2013, 57, p 46–56

L.P.P. Chokkakula, B.V. Sarada, K.V. Rajulapati, T.N. Rao, and G. Sundararajan, A New Electrochemical Approach for the Synthesis of Copper-Graphene Nanocomposite Foils with High Hardness, Sci. Rep., 2014, 4, p 4049

U. Wiklund, J. Gunnars, and S. Hogmark, Influence of Residual Stresses on Fracture and Delamination of Thin Hard Coatings, Wear, 1999, 232, p 262–269

S. Suresh, Graded Materials for Resistance to Contact Deformation and Damage, Science, 2001, 80(292), p 2447–2451

S. Banthia, S. Sengupta, S. Das, and K. Das, Cu, Cu-SiC Functionally Graded Coating for Protection Against Corrosion and Wear, Surf. Coat. Technol., 2019, 374, p 833–844

S. Banthia, S. Sengupta, S. Das, and K. Das, Synthesis and Characterization of Novel Cu, Cu-SiC Functionally Graded Coating by Pulse Reverse Electrodeposition, Appl. Surf. Sci., 2019, 467–468, p 567–579

V. Torabinejad, M. Aliofkhazraei, A.S. Rouhaghdam, and M.H. Allahyarzadeh, Functionally Graded Coating of Ni-Fe Fabricated by Pulse Electrodeposition, J. Mater. Eng. Perform., 2016, 25, p 5494–5501

M.H. Allahyarzadeh, M. Aliofkhazraei, A.R. Sabour Rouhaghdam, and V. Torabinejad, Gradient Electrodeposition of Ni-Cu-W(alumina) Nanocomposite Coating, Mater. Des., 2016, 107, p 74–81

V. Torabinejad, A.S. Rouhaghdam, M. Aliofkhazraei, and M.H. Allahyarzadeh, Ni-Fe-Al2O3 Electrodeposited Nanocomposite Coating with Functionally Graded Microstructure, Bull. Mater. Sci., 2016, 39, p 857–864

M.H. Allahyarzadeh and M. Aliofkhazraei, Functionally graded nickel–tungsten coating: electrodeposition, corrosion and wear behaviour, Can. Metall. Q., 2016, 55, p 303–311.

G133-05, Linearly Reciprocating Ball-on-Flat Sliding Wear, ASTM Int, 2016, i, p 1–9

Standard Test Methods for Measuring Resistance of Electrical Connections Static, 2003, 02, p 1–6

K. Kim, J. Lee, Reciprocal sliding friction model for an electro-deposited coating and its parameter estimation using Markov Chain Monte Carlo method, Materials (Basel), 2016, 9

C.H. Hager, S. Sharma, and J.H. Sanders, Characterization of Mixed and Gross Slip Fretting Wear Regimes in Ti6Al4V Interfaces at Room Temperature, Wear, 2004, 257, p 167–180

K. Gotlib-Vainshtein, O. Girshevitz, C.N. Sukenik, D. Barlam, and S.R. Cohen, A Nanometric Cushion for Enhancing Scratch and Wear Resistance of Hard Films, Beilstein J. Nanotechnol., 2014, 5, p 1005–1015

X. Liu, Z. Cai, J. He, J. Peng, and M. Zhu, Effect of Elevated Temperature on Fretting Wear Under Electric Contact, Wear, 2017, 376–377, p 643–665

Acknowledgment

The authors would like to thank Mr S. K. Karan, Technical Superintendent, Department of Physics, Indian Institute of Technology Kharagpur to help in measuring the ECR.

Funding

The authors declare no competing financial interest.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human Participants and/or Animals

This work does not involve any human participants and/or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Banthia, S., Amid, M., Sengupta, S. et al. Reciprocating Sliding Wear of Cu, Cu-SiC Functionally Graded Coating on Electrical Contact. J. of Materi Eng and Perform 29, 3930–3940 (2020). https://doi.org/10.1007/s11665-020-04878-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04878-8