Abstract

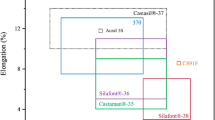

In this study, wire arc additive manufacturing process is employed to fabricate a low-carbon low-alloy steel block, using an ER70S-6 solid wire. Three sets of samples with different orientations, including perpendicular (Vertical), parallel (Horizontal), and 45° (45-degree) relative to the deposition plane, were prepared in order to investigate the anisotropy in mechanical properties and microstructure of the fabricated part. Both Horizontal and 45-degree samples showed a uniform microstructure containing mostly ferritic grains with a small volume fraction of pearlite at their grain boundaries. Differently, a periodic microstructure was detected in the Vertical sample, consisting of a combination of acicular ferrite, bainite, and allotriomorphic ferrite formed in the interlayer regions in addition to polygonal ferrite within the melt pools’ center. Moreover, the uniaxial tensile and Charpy impact results exhibited isotropic tensile, yield, elongation, and impact properties for both Horizontal and 45-degree samples; however, the Vertical sample showed a lower mechanical performance. The improved mechanical properties of the Horizontal and 45-degree samples were correlated to their uniform ferritic microstructure.

Similar content being viewed by others

References

W.E. Frazier, Metal Additive Manufacturing: A Review, J. Mater. Eng. Perform., 2014, 23(6), p 1917–1928.

A. Taşdemir and S. Nohut, An Overview of Wire Arc Additive Manufacturing (WAAM) in Shipbuilding Industry, Ships Offshore Struct., 2020 https://doi.org/10.1080/17445302.2020.1786232

A.V. Filippov, E.S. Khoroshko, N.N. Shamarin, N.L. Savchenko, E.N. Moskvichev, V.R. Utyaganova, E.A. Kolubaev, A.Y. Smolin and S.Y. Tarasov, Characterization of Gradient CuAl-B4C Composites Additively Manufactured Using a Combination of Wire-Feed and Powder-Bed Electron Beam Deposition Methods, J. Alloys Compd., 2021, 859, p 157824. https://doi.org/10.1016/j.jallcom.2020.157824

M. Ghaffari, A.V. Nemani, M. Rafieazad and A. Nasiri, Effect of Solidification Defects and HAZ Softening on the Anisotropic Mechanical Properties of a Wire Arc Additive-Manufactured Low-Carbon Low-Alloy Steel Part, JOM, 2019, 71(11), p 4215–4224. https://doi.org/10.1007/s11837-019-03773-5

J.P. Oliveira, B. Crispim, Z. Zeng, T. Omori, F.M.B. Fernandes and R.M. Miranda, Microstructure and Mechanical Properties of Gas Tungsten Arc Welded Cu-Al-Mn Shape Memory Alloy Rods, J. Mater. Process. Technol., 2019, 271, p 93–100. https://doi.org/10.1016/j.jmatprotec.2019.03.020

F. Martina, J. Mehnen, S.W. Williams, P. Colegrove and F. Wang, Investigation of the Benefits of Plasma Deposition for the Additive Layer Manufacture of Ti-6Al-4V, J. Mater. Process. Technol., 2012, 212(6), p 1377–1386. https://doi.org/10.1016/j.jmatprotec.2012.02.002

Y. Wang, X. Chen, S. Konovalov, C. Su, A.N. Siddiquee and N. Gangil, In-Situ Wire-Feed Additive Manufacturing of Cu-Al Alloy by Addition of Silicon, Appl. Surf. Sci., 2019, 487, p 1366–1375. https://doi.org/10.1016/j.apsusc.2019.05.068

P.P. Nikam, D. Arun, K.D. Ramkumar and N. Sivashanmugam, Microstructure Characterization and Tensile Properties of CMT-Based Wire plus Arc Additive Manufactured ER2594, Mater. Charact., 2020, 169, p 110671. https://doi.org/10.1016/j.matchar.2020.110671

M. Rafieazad, M. Ghaffari, A.V. Nemani and A. Nasiri, Microstructural Evolution and Mechanical Properties of a Low-Carbon Low-Alloy Steel Produced by Wire Arc Additive Manufacturing, Int. J. Adv. Manuf. Technol., 2019 https://doi.org/10.1007/s00170-019-04393-8

S. Li, J. Ning, G.-F. Zhang, L.-J. Zhang, J. Wu and L.-X. Zhang, Microstructural and Mechanical Properties of Wire-Arc Additively Manufactured Al-Zn-Mg Aluminum Alloy: The Comparison of as-Deposited and Heat-Treated Samples, Vacuum, 2021, 184, p 109860. https://doi.org/10.1016/j.vacuum.2020.109860

W. Wu, J. Xue, L. Wang, Z. Zhang, Y. Hu and C. Dong, Forming Process, Microstructure, and Mechanical Properties of Thin-Walled 316L Stainless Steel Using Speed-Cold-Welding Additive Manufacturing, Metals (Basel), 2019 https://doi.org/10.3390/met9010109

A.V. Nemani, M. Ghaffari and A. Nasiri, Comparison of Microstructural Characteristics and Mechanical Properties of Shipbuilding Steel Plates Fabricated by Conventional Rolling versus Wire Arc Additive Manufacturing, Addit. Manuf., 2020, 32, p 101086. https://doi.org/10.1016/j.addma.2020.101086

M. Ghaffari, A.V. Nemani and A. Nasiri, Interfacial Bonding Between a Wire Arc Additive Manufactured 420 Martensitic Stainless Steel Part and Its Wrought Base Plate, Mater. Chem. Phys., 2020, 251, p 123199. https://doi.org/10.1016/j.matchemphys.2020.123199

A.V. Nemani, M. Ghaffari and A. Nasiri, On the Post-Printing Heat Treatment of a Wire Arc Additively Manufactured ER70S Part, Materials (Basel), 2020 https://doi.org/10.3390/ma13122795

X. Zhang, Q. Zhou, K. Wang, Y. Peng, J. Ding, J. Kong and S. Williams, Study on Microstructure and Tensile Properties of High Nitrogen Cr-Mn Steel Processed by CMT Wire and Arc Additive Manufacturing, Mater. Des., 2019, 166, p 107611. https://doi.org/10.1016/j.matdes.2019.107611

J.P. Oliveira, A.D. LaLonde and J. Ma, Processing Parameters in Laser Powder Bed Fusion Metal Additive Manufacturing, Mater. Des., 2020, 193, p 108762. https://doi.org/10.1016/j.matdes.2020.108762

J.P. Oliveira, T.G. Santos and R.M. Miranda, Revisiting Fundamental Welding Concepts to Improve Additive Manufacturing: From Theory to Practice, Prog. Mater. Sci., 2020, 107, p 100590. https://doi.org/10.1016/j.pmatsci.2019.100590

L.N. Carter, C. Martin, P.J. Withers and M.M. Attallah, The Influence of the Laser Scan Strategy on Grain Structure and Cracking Behaviour in SLM Powder-Bed Fabricated Nickel Superalloy, J. Alloys Compd., 2014, 615, p 338–347. https://doi.org/10.1016/j.jallcom.2014.06.172

D. Wen, P. Long, J. Li, L. Huang and Z. Zheng, Effects of Linear Heat Input on Microstructure and Corrosion Behavior of an Austenitic Stainless Steel Processed by Wire Arc Additive Manufacturing, Vacuum, 2020, 173, p 109131. https://doi.org/10.1016/j.vacuum.2019.109131

X. Fang, H. Li, X. Li, K. Huang, L. Zhang and B. Lu, Effect of Post Heat Treatment on the Microstructure and Mechanical Properties of Wire-Arc Additively Manufactured A357 Alloy Components, Mater. Lett., 2020, 269, p 127674. https://doi.org/10.1016/j.matlet.2020.127674

C. Wang, W. Suder, J. Ding and S. Williams, The Effect of Wire Size on High Deposition Rate Wire and Plasma Arc Additive Manufacture of Ti-6Al-4V, J. Mater. Process. Technol., 2021, 288, p 116842. https://doi.org/10.1016/j.jmatprotec.2020.116842

G.H. Majzoobi, A.H. Mahmoudi and S. Moradi, Ductile to Brittle Failure Transition of HSLA-100 Steel at High Strain Rates and Subzero Temperatures, Eng. Fract. Mech., 2016, 158, p 179–193. https://doi.org/10.1016/j.engfracmech.2016.03.001

ASTM E8M-04, Standard Test Methods for Tension Testing of Metallic Materials [Metric], (West Conshohocken, PA), ASTM International, 2008, doi:https://doi.org/10.1520/E0008M-04.

A. E23-18, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, ASTM Int., 2018, www.astm.org.

J. Ge, J. Lin, H. Fu, Y. Lei and R. Xiao, Tailoring Microstructural Features of Wire Arc Additive Manufacturing 2Cr13 Part via Varying Inter-Layer Dwelling Time, Mater. Lett., 2018, 232, p 11–13. https://doi.org/10.1016/j.matlet.2018.08.037

N. Sridharan, M.W. Noakes, A. Nycz, L.J. Love, R.R. Dehoff and S.S. Babu, On the Toughness Scatter in Low Alloy C-Mn Steel Samples Fabricated Using Wire Arc Additive Manufacturing, Mater. Sci. Eng. A, 2018, 713, p 18–27. https://doi.org/10.1016/j.msea.2017.11.101

B. Shassere, A. Nycz, M.W. Noakes, C. Masuo and N. Sridharan, Correlation of Microstructure and Mechanical Properties of Metal Big Area Additive Manufacturing, Appl. Sci., 2019 https://doi.org/10.3390/app9040787

A. Waqas, X. Qin, J. Xiong, C. Zheng and H. Wang, Analysis of Ductile Fracture Obtained by Charpy Impact Test of a Steel Structure Created by Robot-Assisted GMAW-Based Additive Manufacturing, Metals (Basel), 2019 https://doi.org/10.3390/met9111208

Y. Zhao, X. Tong, X.H. Wei, S.S. Xu, S. Lan, X.-L. Wang and Z.W. Zhang, Effects of Microstructure on Crack Resistance and Low-Temperature Toughness of Ultra-Low Carbon High Strength Steel, Int. J. Plast., 2019, 116, p 203–215. https://doi.org/10.1016/j.ijplas.2019.01.004

G. Chen, H. Luo, H. Yang, Z. Han, Z. Lin, Z. Zhang and Y. Su, Effects of the Welding Inclusion and Notch on the Fracture Behaviors of Low-Alloy Steel, J. Mater. Res. Technol., 2019, 8(1), p 447–456. https://doi.org/10.1016/j.jmrt.2018.04.005

X. Xu, S. Ganguly, J. Ding, S. Guo, S. Williams and F. Martina, Microstructural Evolution and Mechanical Properties of Maraging Steel Produced by Wire+arc Additive Manufacture Process, Mater. Charact., 2017, 5, p 10.

A. Pineau, A.A. Benzerga and T. Pardoen, Failure of Metals I: Brittle and Ductile Fracture, Acta Mater., 2016, 107, p 424–483. https://doi.org/10.1016/j.actamat.2015.12.034

N. Huda, A.R.H. Midawi, J. Gianetto, R. Lazor and A.P. Gerlich, Influence of Martensite-Austenite (MA) on Impact Toughness of X80 Line Pipe Steels, Mater. Sci. Eng. A, 2016, 662, p 481–491. https://doi.org/10.1016/j.msea.2016.03.095

Acknowledgments

The authors acknowledge the support of Natural Sciences and Engineering Research Council of Canada (NSERC), Canada Research Chair (CRC) program, Memorial University of Newfoundland, and Dalhousie University for sponsoring this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

Rafieazad, M., Nemani, A.V., Ghaffari, M. et al. On Microstructure and Mechanical Properties of a Low-Carbon Low-Alloy Steel Block Fabricated by Wire Arc Additive Manufacturing. J. of Materi Eng and Perform 30, 4937–4945 (2021). https://doi.org/10.1007/s11665-021-05568-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05568-9