Abstract

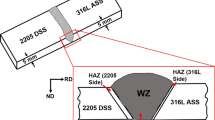

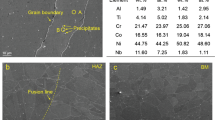

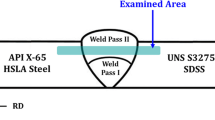

The aim of this work was to characterize the microstructure-mechanical response relationships in UNS N08825/AISI 316L welds by means of electron backscatter diffraction analysis. Welding was conducted by ERNiCrMo-3 and ER308L filler wires. It was indicated that a significant increase in fractions of low Σ coincidence site lattice (CSL) boundaries occurred in UNS N08825 heat-affected zones (HAZs), whereas a small number of the boundaries formed in the AISI 316L HAZs and weld zones were of low ΣCSL types. Abnormal grain growth took place in the HAZs leading to changes in the initial texture components of the alloys. It was also demonstrated that the type of the used filler wire was a factor influencing the microtexture components formed within the HAZs. According to the results of mechanical tests, the weldment employing the ERNiCrMo-3 filler wire exhibited superior hardness, tensile strength, and elongation. Moreover, the occurrence of the abnormal grain growth in UNS N08825 HAZs had no negative effects on the tensile response of the weldments as a result of the activation of texture strengthening mechanism. Based on the obtained results, the ERNiCrMo-3 filler metal was recommended to fabricate the joint.

Similar content being viewed by others

References

K.D. Ramkumar, P.S. Goutham, V.R. Krishna, A. Chandrasekhar, S. Dev, W. Sunny, S. Prabhakaran, S. Kalainathan and R. Sridhar, Influence of Laser Peening on the Tensile Strength and Impact Toughness of Dissimilar Welds of Inconel 625 and UNS S32205, Mater. Sci. Eng. A., 2016, 676, p 88–99. https://doi.org/10.1016/j.msea.2016.08.104

S. Meco, S. Ganguly and S. Williams, Effect of Laser Processing Parameters on the Formation of Intermetallic Compounds in Fe-Al Dissimilar Welding, J. Mater. Eng. Perform., 2014, 23, p 3361–3370. https://doi.org/10.1007/s11665-014-1106-5

S. Sharma, R.V. Taiwade and H. Vashishtha, Effect of Continuous and Pulsed Current Gas Tungsten Arc Welding on Dissimilar Weldments Between Hastelloy C-276/AISI 321 Austenitic Stainless Steel, J. Mater. Eng. Perform., 2017, 26, p 1146–1157. https://doi.org/10.1007/s11665-017-2570-5

S. Zhou, G. Ma, D. Chai, F. Niu, J. Dong and D. Wu, Nickel-Based Alloy/Austenitic Stainless Steel Dissimilar Weld Properties Prediction on Asymmetric Distribution of Laser Energy, Opt. Laser Technol., 2016, 81, p 33–39. https://doi.org/10.1016/j.optlastec.2016.01.017

M.A. Derakhshi, J. Kangazian and M. Shamanian, Electron Beam Welding of Inconel 617 to AISI 310: Corrosion Behavior of Weld Metal, Vacuum, 2019, 161, p 371–374. https://doi.org/10.1016/j.vacuum.2019.01.005

M. Tümer, T. Mert and T. Karahan, Investigation of Microstructure, Mechanical, and Corrosion Behavior of Nickel-Based Alloy 625/Duplex Stainless Steel UNS S32205 Dissimilar Weldments using ERNiCrMo-3 Filler Metal, Weld World, 2020 https://doi.org/10.1007/s40194-020-01011-0

M. Safari, H. Mostaan and E. Derakhshan, Microstructual and Mechanical Studies of the Dissimilar Tabular Joints of Incoloy Alloy 825 and AISI 316 Stainless Steel, J. Marine Eng. Technol., 2018 https://doi.org/10.1080/20464177.2018.15088055

T. Ramkumar, M. Selvakumar, P. Narayanasamy, A.A. Begam, P. Mathavan and A.A. Raj, Studies on the Structural Property, Mechanical Relationships and Corrosion Behaviour of Inconel 718 and SS 316L Dissimilar Joints by TIG Welding Without using Activated Flux, J. Manuf. Process., 2017, 30, p 290–298. https://doi.org/10.1016/j.jmapro.2017.09.028

G. Chandrasekar, C. Kailasanathan and M. Vasundara, Investigation on Un-Peened and Laser Shock Peened Dissimilar Weldments of Inconel 600 and AISI 316L Fabricated using Activated-TIG Welding Technique, J. Manuf. Process., 2018, 35, p 466–478. https://doi.org/10.1016/j.jmapro.2018.09.004

H. Ramakrishnan, G. Sakthi, V. Santhosh, M. Ravichandran, Mechanical, Microstructural Evaluation and Optimisation of Laser Welded AISI 316l and Incoloy 825 (UNS SO8825) Alloy, AIP Conference Proceedings. Vol. 2283. No. 1. AIP Publishing LLC (2020)

A. Kulkarni, D.K. Dwivedi and M. Vasudevan, Microstructure and Mechanical Properties of A-TIG Welded AISI 316L SS-Alloy 800 Dissimilar Metal Joint, Mater. Sci. Eng. A., 2020, 790, p 139685. https://doi.org/10.1016/j.msea.2020.139685

J. Kangazian and M. Shamanian, Micro-Texture and Corrosion Behavior of Dissimilar Joints of UNS S32750 Stainless Steel/UNS N08825 Ni-Based Superalloy, Mater. Charact., 2019, 155, p 109802. https://doi.org/10.1016/j.matchar.2019.109802

Beausir J-JFB. Analysis tools for Electron and X-Ray diffraction; 2017. ATEX-Software; 2017. www.atex-software.eu

J.C. Lippold and D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, Wiley, Hoboken, 2005.

Q. Bai, Q. Zhao, S. Xia, B. Wang, B. Zhou and C. Su, Evolution of Grain Boundary Character Distributions in Alloy 825 Tubes during High Temperature Annealing: Is Grain Boundary Engineering Achieved through Recrystallization or Grain Growth?, Mater. Charact., 2017, 123, p 178–188. https://doi.org/10.1016/j.matchar.2016.11.016

S. Goel, H. Mehtani, S. Yao, I. Samajdar, U.T.A. Klement and S. Joshi, As-Built and Post-treated Microstructures of an Electron Beam Melting (EBM) Produced Nickel-Based Superalloy, Metall. Mater. Trans. A., 2020 https://doi.org/10.1007/s11661-020-06037-z

S. Tokita, H. Kokawa, Y.S. Sato and H.T. Fujii, In situ EBSD Observation of Grain Boundary Character Distribution Evolution during Thermomechanical Process Used for Grain Boundary Engineering of 304 Austenitic Stainless Steel, Mater. Charact., 2017, 131, p 31–38. https://doi.org/10.1016/j.matchar.2017.06.032

G. Sayiram and N. Arivazhagan, Microstructural Characterization of Dissimilar Welds Between Incoloy 800H and 321 Austenitic Stainless Steel, Mater. Charact., 2015, 102, p 180–188. https://doi.org/10.1016/j.matchar.2015.03.006

J.D. Busch, J.J. Debarbadillo and M.J.M. Krane, Flux Entrapment and Titanium Nitride Defects in Electroslag Remelting of Incoloy Alloys 800 and 825, Metall. Mater. Trans. A., 2013, 44, p 5295–5303. https://doi.org/10.1007/s11661-013-1659-1

M. Sireesha, V. Shankar, S.K. Albert and S. Sundaresan, Microstructural Features of Dissimilar Welds Between 316LN Austenitic Stainless Steel and Alloy 800, Mater. Sci. Eng. A., 2000, 292, p 74–82.

C. Hu, S. Xia, H. Li, T. Liu, B. Zhou, W. Chen and N. Wang, Improving the Intergranular Corrosion Resistance of 304 Stainless Steel by Grain Boundary Network Control, Corros. Sci., 2011, 53, p 1880–1886. https://doi.org/10.1016/j.corsci.2011.02.005

S. Emami and T. Saeid, A Comparative Study on the Microstructure Development of Friction Stir Welded 304 Austenitic, 430 Ferritic, and 2205 Duplex Stainless Steels, Mater. Chem. Phys., 2019, 237, p 121833. https://doi.org/10.1016/j.matchemphys.2019.121833

H. Ming, Z. Zhang, J. Wang, E. Han, P. Wang and Z. Sun, Microstructure of a Safe-End Dissimilar Metal Weld Joint (SA508-52-316L) Prepared by Narrow-Gap GTAW, Mater. Charact., 2017, 123, p 233–243. https://doi.org/10.1016/j.matchar.2016.11.029

J.C. Lippold, Welding Matellurgy and Weldbility, Wiley, Hoboken, 2015.

R.S. Razavi, Laser Beam Welding of Waspaloy: Characterization and Corrosion Behavior Evaluation, Optic Laser Technol., 2016, 82, p 113–120. https://doi.org/10.1016/j.optlastec.2016.03.011

D. Jadhav, S. Dadbakhsh, L. Goossens, J. Kruth, J. Van Humbeeck and K. Vanmeensel, Influence of Selective Laser Melting Process Parameters on Texture Evolution in Pure Copper, J. Mater. Process. Technol., 2019, 270, p 47–58. https://doi.org/10.1016/j.jmatprotec.2019.02.022

J.N. DuPont, J.C. Lippold and S.D. Kiser, Welding Metallurgy and Weldability of Nickel Base Alloys, Wiley, Hoboken, 2009.

K.D. Ramkumar, A. Chandrasekhar and A. Kumar, Effect of Filler Metals on the Structure—Property Relationships of Continuous and Pulsed Current GTA Welds of AISI 430 and AISI 904L, Metallogr. Microstruct. Anal., 2015, 4, p 525–541. https://doi.org/10.1007/s13632-015-0236-y

K.D. Ramkumar, A. Singh, S. Raghuvanshi, A. Bajpai, T. Solanki, M. Arivarasu, N. Arivazhagan and S. Narayanan, Metallurgical and Mechanical Characterization of Dissimilar Welds of Austenitic Stainless Steel and Super-Duplex Stainless Steel—A Comparative Study, J. Manuf. Process., 2015, 19, p 212–232. https://doi.org/10.1016/j.jmapro.2015.04.005

R.S.K. Devendranath and R.N. Arivazhagan, Characterization of Microstructure, Strength , and Toughness of Dissimilar Weldments of Inconel 625 and Duplex Stainless Steel SAF 2205, Acta Metall. Sinica (Engl. Lett.), 2014, 27, p 1018–1030. https://doi.org/10.1007/s40195-014-0116-5

C.C. Silva, H. Cordeiro, D. Miranda, M. Ferreira, J. Pereira, C. Ramos, M. Afonso and A. Jose, Original Article New Insight on the Solidification Path of an Alloy 625 Weld Overlay, Integr. Med. Res., 2013, 2, p 228–237. https://doi.org/10.1016/j.jmrt.2013.02.008

A. Moteshakker, I. Danaee, S. Moeinifar and A. Ashrafi, Hardness and Tensile Properties of Dissimilar Welds Joints Between SAF 2205 and AISI 316L, Sci. Technol. Weld. Join., 2015, 21, p 1–10. https://doi.org/10.1179/1362171815Y.0000000062

J. Verma and R.V. Taiwade, Effect of Welding Processes and Conditions on the Microstructure, Mechanical Properties and Corrosion Resistance of Duplex Stainless Steel Weldments—A Review, J. Manuf. Process., 2017, 25, p 134–152. https://doi.org/10.1016/j.jmapro.2016.11.003

A. Eghlimi, M. Shamanian, M. Eskandarian, A. Zabolian and J.A. Szpunar, Characterization of Microstructure and Texture Across Dissimilar Super Duplex/Austenitic Stainless Steel Weldment Joint by Super Duplex Filler Metal, Mater. Charact., 2015, 106, p 27–35. https://doi.org/10.1016/j.matchar.2015.05.017

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, Elsevier, Amsterdam, 2012.

K.D. Ramkumar, A. Harendra, A. Anil, M. Atharva, C. Vishnu, D. Arun, M.G. Vijay, W. Sunny, A. Chatterjee, J. Abraham and J. Abraham, Microstructure, Mechanical Properties and Biocorrosion Behavior of Dissimilar Welds of AISI 904L and UNS S32750, J. Manuf. Process., 2017, 30, p 27–40. https://doi.org/10.1016/j.jmapro.2017.09.001

H. Shah Hosseini, M. Shamanian and A. Kermanpur, Characterization of Microstructures and Mechanical Properties of Inconel 617/310 Stainless Steel Dissimilar Welds, Mater. Charact., 2011, 62, p 425–431. https://doi.org/10.1016/j.matchar.2011.02.003

A.H. Saedi, E. Hajjari and S.M. Sadrossadat, Microstructural Characterization and Mechanical Properties of TIG-Welded API 5L X60 HSLA Steel and AISI 310S Stainless Steel Dissimilar Joints, Metall. Mater. Trans. A., 2018, 49(11), p 5497–5508. https://doi.org/10.1007/s11661-018-4890-y

H.B. Li, Z.H. Jiang, H. Feng, S.C. Zhang, L. Li, P.D. Han, R.D.K. Misra and J.Z. Li, Microstructure, Mechanical and Corrosion Properties of Friction Stir Welded High Nitrogen Nickel-Free Austenitic Stainless Steel, Mater. Des., 2015, 84, p 291–299. https://doi.org/10.1016/j.matdes.2015.06.103

A. Keshavarzkermani, R. Esmaeilizadeh, U. Ali, P.D. Enrique, Y. Mahmoodkhani, N.Y. Zhou, A. Bonakdar and E. Toyserkani, Controlling Mechanical Properties of Additively Manufactured Hastelloy X by Altering Solidification Pattern during Laser Powder-Bed Fusion, Mater. Sci. Eng. A., 2019, 762, p 138081. https://doi.org/10.1016/j.msea.2019.138081

J. Myoung, J. Min, J. Yu, J. Gi, Y. Seong, S. Hong and H. Seop, Effects of Microstructure and Internal Defects on Mechanical Anisotropy and Asymmetry of Selective Laser-Melted 316L Austenitic Stainless Steel, Mater. Sci. Eng. A., 2019, 763, p 138152.

J. Min, J. Choe, H. Keun, S. Son, J. Jung, T. Kim, J. Yu, J. Gi and H. Seop, Synergetic Strengthening of Additively Manufactured (CoCrFeMnNi) 99 C 1 High-Entropy Alloy by Heterogeneous Anisotropic Microstructure, Addit. Manuf., 2020, 35, p 101333. https://doi.org/10.1016/j.addma.2020.101333

S.Y. Liu, H.Q. Li, C.X. Qin, R. Zong and X.Y. Fang, The Effect of Energy Density on Texture and Mechanical Anisotropy in Selective Laser Melted Inconel 718, Mater. Des., 2020, 191, p 108642. https://doi.org/10.1016/j.matdes.2020.108642

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical standards

The article was conducted according to ethical standards. This manuscript has been prepared by the contribution of all authors, it is the original author’s work, it has been solely submitted to this journal, and if accepted, it will not be submitted to other journals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shamanian, M., Babajani, M., Kangazian, J. et al. Characterization of Microstructure, Microtexture, and Mechanical Response in UNS N08825 Superalloy/AISI 316L Stainless Steel Welds by Electron Backscatter Diffraction Analysis. J. of Materi Eng and Perform 30, 6009–6026 (2021). https://doi.org/10.1007/s11665-021-05838-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05838-6