Abstract

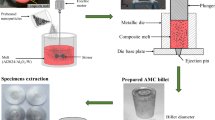

The AZ91 magnesium alloy, used commonly as a biodegradable material in biomedical applications, is generally formed by conventional casting method (CCM) and high-pressure die casting method (HPDCM). The AZ91 alloys exhibit poor machinability with conventional chip removal methods since they degrade at elevated temperatures. In this study, the wire electric discharge machining (WEDM) was presented as a candidate process to machine the AZ91 alloy since no cutting stresses and plastic deformations were applied by the cutting tool to the part causing elevated temperatures. In this context, the WEDM machinability of the AZ91 alloy samples produced by cold chamber HPDCM and CCM at different process parameters, was experimentally investigated. The machining performance outputs (the machining current (I), the machining rate (MR), the average surface roughness (Ra), and surface topography) were found for the varying process parameters [pulse time (ts), pulse-off time (toff), dielectric flushing pressure (Pd), and wire speed (Vw)]. The present study revealed that the I and the MR were significantly dependent on the density, the porosity, and the micro structure of the samples, and the HPDCM samples gave the higher MR and the smoother surface than that of the CCM.

Similar content being viewed by others

References

M. M. Avedesian and H. Baker, ASM specialty handbook: Magnesium and magnesium alloys, ASM International, USA, 1999.

C. Blawert, N. Hort and K.U. Kainer, Automotive applications of magnesium and its alloys, Trans.- Indian Inst. Metals, 2004, 57(4), p 397-408.

M.V. Segal, Materials processing by simple shear, Mater. Sci. Eng., A, 1995, 197(2), p p157-164.

K. Máthis, G. Jenő and N.H. Nam, Microstructure and mechanical behavior of AZ91 Mg alloy processed by equal channel angular pressing, J. Alloy. Compd., 2005, 394(1-2), p 194-199.

E. Koç, M. Ünal, Y. Türen and E. Candan, Effect of TIN on Casting and Mechanical Properties of AZ91 Magnesium Alloy, 5. International Advanced Technologies Symposium (IATS’09), 13–15 May 2009, Karabük, Turkey

A.S.J. Al-Zubaydi, A.P. Zhilyaev, S.C. Wang and P.A.S. Reed, Superplastic behaviour of AZ91 magnesium alloy processed by high-pressure torsion, Mater. Sci. Eng., A, 2015, 637, p 1-11.

Y. Türen, Effect of Sn addition on microstructure, mechanical and casting properties of AZ91 alloy, Mater. Des., 2013, 49, p 1009-1015.

E. Uhlmann, S. Piltz and D. Oberschmidt, Machining of micro rotational parts by wire electrical discharge grinding, Prod. Eng. Res. Devel., 2008, 2(3), p 227-233.

F. Klocke, M. Schwade, A. Klink and A. Kopp, EDM machining capabilities of magnesium (Mg) alloy WE43 for medical applications, Procedia Eng., 2011, 19, p 190-195.

A. Mostafapor and H. Vahedi, Wire electrical discharge machining of AZ91 magnesium alloy; investigation of effect of process input parameters on performance characteristics, Eng. Res. Express, 2019, 1(1), p 015005.

U. Köklü, S. Morkavuk and L. Urtekin, Effects of the drill flute number on drilling of a casted AZ91 magnesium alloy, Mater. Testing, 2019, 61(3), p 260-266.

Ş Yazman, U. Köklü, L. Urtekin, S. Morkavuk and L. Gemi, Experimental study on the effects of cold chamber die casting parameters on high-speed drilling machinability of casted AZ91 alloy, J. Manuf. Process., 2020, 57, p 136-152.

Acknowledgment

The production of HPDCM samples was carried out under the scope of the MMF.A3.17.003 coded Scientific Research Project (BAP). The authors would like to thank Kırşehir Ahi Evran University (Turkey) BAP Division.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Urtekin, L., Özerkan, H.B., Cogun, C. et al. Experimental Investigation on Wire Electric Discharge Machining of Biodegradable AZ91 Mg Alloy. J. of Materi Eng and Perform 30, 7752–7761 (2021). https://doi.org/10.1007/s11665-021-05939-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05939-2