Abstract

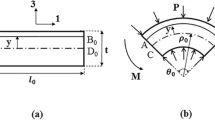

Press-brake bending is one of the important sheet metal forming processes widely used to fabricate different angles and channels in automotive applications. Plastic deformation of material during bending generates elastic stress waves known as acoustic emission (AE), enabling online monitoring of the bending process. The analysis of these stress waves helps in process characterization and aids in the identification of defects. The non-homogeneous plastic deformation that occurs during bending leads to the development of residual stress (RS) in the bend regions after forming. The locked-in residual stresses that remain after bending are measured using the x-ray diffraction method. The present study aims to use the AE technique for online bend monitoring of austenitic stainless steel (SS) of type 304L and correlate the AE parameters acquired during bending with the final locked-in RS present in the bend regions. Toward this, SS 304L sheets were bent to various bend angles, viz. 45°, 60°, 90°, 108°, 120°, and 135°, along the rolling direction and perpendicular to the rolling direction. Among the many AE parameters derived from the analysis of AE signals, it is shown that normalized cumulative counts and energy increase with bend angle. The increase in AE is well correlated with the RS that develops due to plastic deformation. The observed correlations between AE parameters acquired during bending and RS measured after bending are discussed.

Similar content being viewed by others

References

D. Dornfeld, Application of Acoustic Emission Techniques in Manufacturing, NDT E Int., 1992, 25, p 259.

T. Jayakumar, C.K. Mukhopadhyay, S. Venugopal and S.L. Mannan, Baldev Raj, A Review of the Application of Acoustic Emission Techniques for Monitoring Forming and Grinding Processes, J. Mater. Process. Technol., 2005, 159, p 48.

C.K. Mukhopadhyay, S. Venugopal, T. Jayakumar, S.L. Mannan, B. Baldev Raj, R. Chatterji, V. Srinivasan, G.M. Gopalakrishnan and R.S. Tripathi, Acoustic Emission (AE) Monitoring of Open Die and Closed Die Forging Processes of Al Alloy, Mater. Manuf. Process., 2007, 22, p 887.

M.S.H. Bhuiyan, I.A. Choudhury, M. Dahari, Y. Nukman and S.Z. Dawal, Application of Acoustic Emission Sensor to Investigate the Frequency of Tool Wear and Plastic Deformation in Tool Condition Monitoring, Meas., 2016, 92, p 208.

S.Y. Liang and D.A. Dornfeld, ASME, Characterization of Sheet Metal Forming using acoustic Emission, J. Eng. Mater. Technol., 1990, 112, p 44.

B.-A. Behrens, S. Hübner and K. Wölki, Acoustic Emission-A Promising and Challenging Technique for Process Monitoring in Sheet Metal Forming, J. Manuf. Process., 2017, 29, p 281.

G.E. Dieter, Mechanical Metallurgy, 3rd ed. McGraw-Hill, New York, 1986, p 557–559

R.M. McMeeking, E.H. Lee, Proceedings 28th Sagamore Army Materials Research Conference Entitled “Residual Stress and Stress Relaxation, p. 315, Lake Placid, New York (1981).

H.M. Baek, S.K. Hwang, I.H. Son and Y.T. Im, Residual Stress Characteristics in a Non-Circular Drawing Sequence of Pearlitic Steel Wire, Met. Mater. Int., 2016, 22, p 1083.

P.J. Withers, Residual Stress and its Role in Failure, Rep. Prog. Phys., 2007, 70, p 2211.

G. Zijlstra, M. Groen, J. Post, V. Ocelik and JTh.M. De Hosson, On the Role of the Residual State in Product Manufacturing, Mater. Des., 2016, 105, p 375.

M. Groen, G. Zijlstra, D. San-Martin, J. Post and JTh.M. De Hosson, Product Shape Change by Internal Stresses, Mater. Des., 2018, 157, p 492.

A.G. Evans, Residual Stress Measurement using Acoustic Emission, J. Am. Ceram. Soc., 1975, 58, p 239.

A. Naguib, M. EI-Shaib, M. Adel, M. Shehadeh, Predicting the Residual Stresses in steel T-Section Beams using Acoustic Emission Technique, Int. Rev. Mech. Eng., 2015, 9, p 129.

P. Sedek, P. Gotkowski and J. Brozda, Application of Acoustic Emission to Monitor the Course of Plastic Strain in Mechanical Stress Relieved Welded Joints, Arch. Metall. Mater., 2010, 55, p 553.

H.K. Tonshoff, M. Jung, S. Mannel and W. Rietz, Using Acoustic Emission Signals for Monitoring of Production Processes, Ultrasonics, 2000, 37, p 681.

B. Zheng, G. Shu and Q. Jiang, Study on Residual Stress Distributions in Press-Braked Stainless Steel Sections, Int. J. Steel Struct., 2019, 19, p 1483.

Z. Tan, W.B. Li and B. Persson, On Analysis and Measurement of Residual Stresses in the Bending of Sheet Metals, Int. J. Mech. Sci., 1994, 36, p 483.

W.M. Quach, J.G. Teng and K.F. Chung, Finite Element Predictions of Residual Stresses in Press-Braked Thin-Walled Steel Sections, Eng. Struct., 2006, 28, p 1609.

C.C. Weng and R.N. White, Residual Stresses in Cold-Bent Thick Steel plates, J. Struct. Eng., 1990, 116, p 40.

ASTM International, E517–19, Standard Test Method for Plastic Strain Ratio r for Sheet Metal, ASTM International, West Conshohocken, PA, 2019.

M. Ahmadi, B.M. Sadaghi and H. Arabi, Experimental and Numerical Investigation of V-bent Anisotropic 304L SS Sheet with Spring-Forward Considering Deformation-Induced Martensitic Transformation, Mater. Des., 2017, 123, p 211.

https://www.machinemfg.com/calculation-of-sheet-metal-bending-force-in-air-bending/

I.C. Noyan and J.B. Cohen, Residual Stress-Measurement by Diffraction and Interpretation, Springer, Berlin, 1987, p 117

S. Genna, I. Papa and C. Leone, A Preliminary Study on the Characterization of Laser-Bending Process of AISI 304 Steel Sheets by Acoustic Emission Technique, Int. J. Adv. Manuf. Technol., 2017, 92, p 4111.

B. Venkataraman, C.K. Mukhopadhyay and B. Raj, Effect of Variation of Strain Rate on Thermal and Acoustic Emission During Tensile Deformation of Nuclear Grade AISI Type 316 Stainless Steel, Mater. Sci. Technol., 2004, 20, p 1310.

C.K. Mukhopadhyay, K.K. Ray, T. Jayakumar and B. Raj, ACOUSTIC Emission from Tensile Deformation of Unnotched and Notched Specimens of AISI Type 304 Stainless Steels, Mater. Sci. Eng. A, 1998, 255, p 98.

N. Seemuang, S. Panich and T. Slatter, Bendability Evaluation of Sheet Metals in Three-Point Bending Test by Using Acoustic Emission Features, The J. Appl. Sci., 2017, 16, p 15.

B. Raj, B.B. Jha and P. Rodriguez, Frequency Spectrum Analysis of Acoustic Emission Signal Obtained During Tensile Deformation and Fracture of an AISI 316 Type Stainless Steel, Acta Metall., 1989, 37, p 2211.

C.K. Mukhopadhyay, K.V. Kasiviswanathan and T. Jayakumar, Acoustic Emission During Tensile Deformation of Annealed and Cold-Worked AISI Type 304 Austenitic stainless Steel, J. Mater. Sci., 1993, 28, p 145.

T. Sakai and Y. Shimomura, Texture Observations of Bending by XRD and EBSD Method, Int. J. Mater. Metall. Eng., 2018, 12(3), p 139–143.

P.J. Withers and H.K.D.H. Bhadeshia, Residual Stress. Part 2–NATURE and Origins, Mater. Sci. Technol., 2001, 17, p 366.

F.P. Beer and E.R. Johnston, Mechanics of Materials, 2nd ed. McGraw-Hill, New York, 1992.

M. Vashista and S. Paul, Correlation Between full Width at Half Maximum (FWHM) of XRD Peak with Residual Stress on Ground Surfaces, Philos. Mag., 2012, 92(33), p 4194.

ASTM International, E975–13, Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation, ASTM International, West Conshohocken, PA, 2013.

H. Klug and L.E. Alexander, X-Ray Diffraction Procedures, 2nd ed. John Wiley and Sons, New York, 1974.

H. Fathi, E. Emadoddin, H.R. Mohammadian Semnani and B.M. Sadeghi, Effect of Martensitic Transformation on Springback Behavior of 304L Austenitic Stainless Steel, Mater. Res. Express, 2017, 4(9), p 096510.

X.T. Deng, M. Cheng, S.H. Zhang, H.W. Song and A. M. Taha, Residual Stresses and Martensite Transformations in AISI Austenitic Stainless Steel, Mater. Res. Express, 2018, 6(1), p 016503.

S.S. Hecker, M.G. Stout, K.P. Staudhammer and J.L. Smith, Effects of Strain State and Strain Rate on Deformation Induced Transformation in 304 Stainless Steel: Part I. Magnetic Measurements and Mechanical Behavior, Metall. Trans., 1982, A13, p 619.

S. Lavanya, S. Mahadevan and C.K. Mukhopadhyay, Correlation of Tensile Deformation-Induced Strain in HSLA Steel with Residual Stress Distribution, J. Mater. Eng. Perform., 2019, 28, p 1103.

M. Lebyodkin, K. Amouzou, T. Lebedkina, T. Richeton and A. Roth, Complexity and Anisotropy of Plastic Flow of α-Ti Probed by Acoustic Emission and Local Extensometry, Mater., 2018, 11, p 1061.

Acknowledgments

The authors are thankful to Shri. T. K. Haneef of the NDE Division of Indira Gandhi Centre for Atomic Research (IGCAR) for his help during the AE measurements and the staff of Central Workshop Division, IGCAR, for their help in utilizing the press-brake bending facility. One of the authors, Ms. S. Lavanya would like to acknowledge DAE for the fellowship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lavanya, S., Mahadevan, S., Mukhopadhyay, C.K. et al. Acoustic Emission during Press-Brake Bending of SS 304L Sheets and its Correlation with Residual Stress Distribution after Bending. J. of Materi Eng and Perform 31, 1550–1561 (2022). https://doi.org/10.1007/s11665-021-06250-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06250-w