Abstract

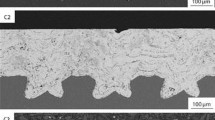

After 125 years of development in combustion engines, the attractiveness of these powerplants still gains a great deal of attention. The efficiency of engines has been increased continuously through numerous innovations during the last years. Especially in the field of motor engineering, consequent friction optimization leads to cost-effective fuel consumption advantages and a CO2 reduction. This is the motivation and adjusting lever of NANOSLIDE® from Mercedes-Benz. The twin wire arc-spraying process of the aluminum bore creates a thin, iron-carbon-alloyed coating which is surface-finished through honing. Due to the continuous development in engines, the coating strategies must be adapted in parallel to achieve a quality-conformed coating result. The most important factors to this end are the controlled indemnification of a minimal coating thickness and a homogeneous coating deposition of the complete bore. A specific system enables the measuring and adjusting of the part and the central plunging of the coating torch into the bore to achieve a homogeneous coating thickness. Before and after measurement of the bore diameter enables conclusions about the coating thickness. A software tool specifically developed for coating deposition can transfer this information to a model that predicts the coating deposition as a function of the coating strategy.

Similar content being viewed by others

Abbreviations

- LDS:

-

Lichtbogendrahtspritzen (German word for “twin wire arc spraying”)

- TWAS:

-

Twin wire arc spraying

- NEDC:

-

New European driving cycle

- OFAT:

-

One factor at time

- DoE:

-

Design of experiments

- CAE:

-

Computer-aided engineering

References

K. Holmberg, P. Andersson, and A. Erdemir, Global Energy Consumption Due to Friction in Passenger Cars, Tribol. Int., 2012, 47, p 221-234

J. Schommers, G. Doll, R. Weller, T. Behr, H. Scheib, M. Löffler, and J. Böhm, Optimizing Friction: The Basis for Safeguarding the Future of Combustion Engines, 33rd International Vienna Motor Symposium, Fortschritt-Berichte VDI, Reihe, 2012

S. Beer, Aluminium-Motorblöcke: Konstruktionen, Werkstoffe, Giessverfahren und Zylinderlaufflächen-Technologien für Leichtbau-Pkw-Motoren, Landsberg/Lech: Verl. Moderne Industrie, 2005

B. Gand, Beschichtung von Zylinderlaufflächen in Aluminium-Kurbelgehäusen, MTZ Motortech Z, 2011, 72(2), p 128-133

J.V. Heberlein, Thermal Spray Fundamentals: From Powder to Part, Springer, New York, 2014

H. Fuchs and M. Wappelhorst, Leichtmetallwerkstoffe für hochbelastete Motorblöcke und Zylinderköpfe, Motortechnische Zeitschrift, 2003, 64(10), p 868-875

K. Bobzin, F. Ernst, J. Zwick, T. Schlaefer, D. Cook, K. Nassenstein, A. Schwenk, F. Schreiber, T. Wenz, G. Flores, and M. Hahn, Coating Bores of Light Metal Engine Blocks with a Nanocomposite Material using the Plasma Transferred Wire Arc Thermal Spray Process, J. Therm. Spray Technol., 2008, 17(3), p 344-351

E. Köhler, S. Beer, C. Klimesch, J. Niehues, and B. Sommer, Leichtbau beim Zylinderkurbelgehäuse für aktuelle und zukünftige Anforderungen, Motortechnische Zeitschrift, 2009, 70(10), p 712-721

M. Hahn and A. Fischer, Characterization of Thermal Spray Coatings for Cylinder Running Surfaces of Diesel Engines, J. Therm. Spray Technol., 2010, 19(5), p 866-872

K. Holdik, M. Hartweg, M. Michel, T. Behr, R. De Zolt, J. Böhm, and F. Spennemann, 125 Years of the Automobile-Daimler’s LDS Cylinder Track Opens up a New Chapter in Engine Construction, Bd. 1, p 46-50, 2011

A. Heuberger, P. Izquierdo, T. Haug, T. Wittrowski, and F. Lampmann, Twin Wire Arc Spraying as a New Coating Technology for Liner-Free Cylinder Bores, Weld. Cut., 2004, 56(6), p 356-361

F. Eichler, A. Fürschuss, M. Hart, R. Schaich, B. Tschamon, R. Illenberger, M. Glose, and W. Zimmermann, Der Antriebsstrang des neuen C63 AMG, 29th International Vienna Motor Symposium, Fortschritt-Berichte VDI, Reihe, 2008

J. Gindele, T. Ramsteiner, J. Fischer, and B. Tschamon, The New 2.0-l High-Performance Four-Cylinder Engine from Mercedes-AMG, MTZ Worldwide, 2013, 74(9), p 26-33

W. Tillmann and B. Krebs, Influence of Handling Parameters on Coating Characteristics in Order to Produce Near-Net-Shape Wear Resistant Coatings, J. Therm. Spray Technol., 2012, 21(3–4), p 644-650

E. DIN, 657, Thermisches Spritzen—Begriffe, Einteilung, 2005

D. Nowotni, C. Wanke, T. Haug, and P. Izquierdo, Internal burner, 2002

A. Newbery, P. Grant, and R. Neiser, The Velocity and Temperature of Steel Droplets During Electric Arc Spraying, Surf. Coat. Technol., 2005, 195(1), p 91-101

A. Pourmousa, J. Mostaghimi, A. Abedini, and S. Chandra, Particle Size Distribution in a Wire-Arc Spraying System, J. Therm. Spray Technol., 2005, 14(4), p 502-510

D. Hale, W. Swank, and D. Haggard, In-Flight Particle Measurements of Twin Wire Electric Arc Sprayed Aluminum, J. Therm. Spray Technol., 1998, 7(1), p 58-63

S.L. Toma, C. Bejinariu, R. Baciu, and S. Radu, The Effect of Frontal Nozzle Geometry and Gas Pressure on the Steel Coating Properties Obtained by Wire Arc Spraying, Surf. Coat. Technol., 2013, 220, p 266-270

W. Tillmann, E. Vogli, and M. Abdulgader, The Correlation Between the Coating Quality and the Moving Direction of the Twin Wire Arc Spraying Gun, J. Therm. Spray Technol., 2010, 19(1–2), p 409-421

N. Hussary and J. Heberlein, Effect of System Parameters on Metal Breakup and Particle Formation in the Wire Arc Spray Process, J. Therm. Spray Technol., 2007, 16(1), p 140-152

H. Liao, Y. Zhu, R. Bolot, C. Coddet, and S. Ma, Size Distribution of Particles from Individual Wires and the Effects of Nozzle Geometry in Twin Wire Arc Spraying, Surf. Coat. Technol., 2005, 200(7), p 2123-2130

M. Planche, H. Liao, and C. Coddet, Relationships Between In-Flight Particle Characteristics and Coating Microstructure with a Twin Wire Arc Spray Process and Different Working Conditions, Surf. Coat. Technol., 2004, 182(2–3), p 215-226

J. König, M. Lahres, O. Methner, B. Wielage, and C. Rupprecht, Methoden zur exakten Positionierung von Beschichtungsaggregaten für eine qualitätsgerechte Beschichtung von Zylinderlaufbahnen, Werkstoffe und Werkstofftechnische Anwendungen, 2013

B.J.J. Wappis, Taschenbuch Null-Fehler-Management, Hanser Fachbuchverlag, 2010

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2014 International Thermal Spray Conference, held May 21-23, 2014, in Barcelona, Spain, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

König, J., Lahres, M. & Methner, O. Quality Designed Twin Wire Arc Spraying of Aluminum Bores. J Therm Spray Tech 24, 63–74 (2015). https://doi.org/10.1007/s11666-014-0170-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0170-6