Abstract

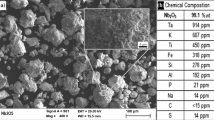

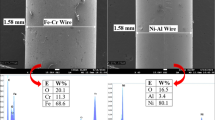

The slurry erosion wear behavior of Ni-20Al2O3 and Ni-10Al2O3-10TiO2 coatings, deposited by high-velocity flame-sprayed technique, has been evaluated in the present investigation. A series of slurry erosion tests were conducted on the deposited surfaces, using an indigenously developed slurry erosion test rig under varying environmental conditions. The effect of identifying operational parameters like rotational speed, average particle size of erodent and erodent concentration on erosion behavior was also evaluated. Surface roughness tester, scanning electron microscope and XRD apparatus were utilized as surface characterization tools, whereas Vickers’s microhardness tester and bond strength tester were employed for mechanical analysis. The SEM observations of eroded specimens were observed to be lying in close proximity to the reported experimental results. Irrespective of the test conditions, Ni-10Al2O3-10TiO2 coating showed better results of slurry erosion performance in comparison with Ni-20Al2O3 coating. Further, each operational test parameter revealed a proportional effect on the erosion rate of both the coatings.

Similar content being viewed by others

References

D.V. Khera and R.S. Chadhawork, Silt Erosion: Trouble for Turbines, Int. Water Power Dam Constr., 2001, 53, p 22-23

S.K. Singal and R. Singh, Impact of Silt on Hydro Turbines, International Himalayan Small Hydropower Summit, Dehradun, 2006, p 218-225

H.S. Grewal, A. Agrawal, and H. Singh, Slurry Erosion Mechanism of Hydroturbine Steel: Effect of Operating Parameters, Tribol. Lett., 2013, 52, p 287-303

M.K. Padhy and R.P. Saini, Effect of Size and Concentration of Silt Particles on Erosion of Pelton Turbine Buckets, Energy, 2009, 34, p 1477-1483

Y. Iwabuchi and S. Sawada, Metallurgical Characteristics of a Large Hydraulic Runner Casting of Type 13Cr-Ni Stainless Steel, ASTM, West Conshohocken, 1982, p 332-354

K. Sugiyama, S. Nakahama, S. Hattori, and K. Nakano, Slurry Wear and Cavitation Erosion of Thermal-Sprayed Cermets, Wear, 2005, 258(5-6), p 768-775

H.S. Grewal, H. Singh, A. Agrawal, and H.S. Arora, Evaluation and Development of Economically Viable Coatings for Erosion Protection of Hydroturbines, Adv. Mater. Res., 2012, 585, p 590-594

H.S. Grewal, S. Bhandari, and H. Singh, Parametric Study of Slurry Erosion of Hydroturbine Steels with and Without Detonation Gun Spray Coatings Using Taguchi Technique, Metall. Mater. Trans., 2012, 43(9), p 3387-3401

P.S. Babu, B. Basu, and G. Sundararajan, The Influence of Erodent Hardness on the Erosion Behavior of Detonation Sprayed WC-12Co Coatings, Wear, 2011, 270, p 903-913

R.J.K. Wood, B.G. Mellor, and M.L. Binfield, Sand Erosion Performance of Detonation Gun Applied Tungsten Carbide/Cobalt–Chromium Coatings, Wear, 1997, 211, p 70-83

H.S. Grewal, A. Agrawal, and H. Singh, Slurry Erosion Performance of Ni-Al2O3 Based Composite Coatings, Tribol. Int., 2013, 66(3), p 296-306

W.B. Xue, C. Wang, Z.W. Deng, R.Y. Chen, Y.L. Li, and T.H. Zhang, Evaluation of the Mechanical Properties of Microarc Oxidation Coatings and 2024 Aluminium Alloy Substrate, J. Phys.: Condens. Matter, 2002, 14, p 10947-10952

C. Duan and V.I.A. Karelin, Abrasive Erosion & Corrosion of Hydraulic Machinery, Imperial College Press, Covent Garden, 2002

M.A. Al-Bukhaiti, S.M. Ahmed, F.M.F. Badran, and K.M. Emara, Effect of Impingement Angle on Slurry Erosion Behaviour and Mechanisms of 1017 Steel and High-Chromium White Cast Iron, Wear, 2007, 262, p 1187-1198

H.M. Clark, Particle Velocity and Size effects in Laboratory Slurry Erosion Measurements or Do you Know What Your Particles are Doing?, Tribol. Int., 2002, 35, p 617-624

H.M. Clark, The Influence of the Flow Field in Slurry Erosion, Wear, 1992, 152, p 223-240

R. Gupta, S.N. Singh, and V. Seshadri, Prediction of Uneven Wear in a Slurry Pipeline on the Basis of Measurements in a Pot Tester, Wear, 1995, 184, p 169-178

B.K. Gandhi, S.N. Singh, and V. Seshadri, Study of the Parametric Dependence of Erosion Wear for the Parallel Flow of Solid–Liquid Mixtures, Tribol. Int., 1999, 32, p 275-282

G.R. Desale, B.K. Gandhi, and S.C. Jain, Effect of Erodent Properties on Erosion Wear of Ductile Type Materials, Wear, 2006, 261, p 914-921

H. Singh, K. Goyal, and D.K. Goyal, Experimental Investigations on Slurry Erosion Behaviour of HVOF and HVOLF Sprayed Coatings on Hydraulic Turbine Steel, Trans. Indian Inst. Metals, 2016, doi:10.1007/s12666-016-0956-y

P.N. Rao, Manufacturing Technology, 2nd ed., TMH Publishing Company Limited, New Delhi, 2007

R.W. Heine et al., Principles of Metal Castings, 2nd ed., TMH Publishing Company Limited, New Delhi, 1967

ASTM, Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings, ASTM Standard C 633-01, ASTM International, West Conshohocken, 2001

S. Jia, Y. Zou, J. Xu, J. Wang, and L. Yu, Effect of TiO2 Content on Properties of Al2O3 Thermal Barrier Coatings by Plasma Spraying, Trans. Nonferrous Met. Soc. China, 2015, 25, p 175-183

H. Singh, K. Goyal, and D.K. Goyal, Slurry Erosion Behaviour of Plasma Thermal Sprayed (50%) WC-Co-Cr and Ni-Cr-B-Si Coatings of Different Thickness on CA6NM Turbine Steel Material, Manuf. Sci. Technol., 2014, 2, p 81-92

D.K. Goyal, H. Singh, H. Kumar, and V. Sahni, Slurry Erosion Behavior of HVOF Sprayed WC-10Co-4Cr and Al2O3 + 13TiO2 Coatings on a Turbine Steel, Wear, 2012, 289, p 46-57

S. Bhandari, H. Singh, H.K. Kansal, and V. Rastogi, Slurry Erosion Performance Study of Detonation Gun Sprayed WC-10Co-4Cr Coatings on CF8 M Steel Under Hydro-Accelerated Conditions, J. Therm. Spray Technol., 2012, 21, p 1054-1064

D.K. Goyal, H. Singh, and H. Kumar, An Overview of Slurry Erosion Control by the Application of High Velocity Oxy Fuel Sprayed Coatings, Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol., 2011, 225, p 1092-1105

H. Singh, K. Goyal, and D.K. Goyal, Slurry Erosion Behaviour of Plasma Thermal Sprayed (50%) WC-Co-Cr and Ni-Cr-B-Si Coatings of Different Thickness on CA6NM Turbine Steel Material, Manuf. Sci. Technol., 2014, 2, p 81-92

G. Singh, R.L. Virdi, and K. Goyal, Experimental Investigation of Slurry Erosion Behaviour of Hard Faced AISI, 316L Stainless Steel, Univers. J. Mech. Eng., 2015, 3, p 52-56

S. Bhandari, H. Singh, H.K. Kansal, and V. Rastogi, Slurry Erosion Behavior of Detonation Gun Spray Al2O3 and Al2O3-13TiO2-Coated CF8 M Steel Under Hydro Accelerated Conditions, Tribol. Lett., 2012, 45, p 319-331

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, R., Bhandari, S. & Goyal, A. Slurry Erosion Performance of High-Velocity Flame-Sprayed Ni-20Al2O3 and Ni-10Al2O3-10TiO2 Coatings Under Accelerated Conditions. J Therm Spray Tech 26, 1279–1291 (2017). https://doi.org/10.1007/s11666-017-0598-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0598-6