Abstract

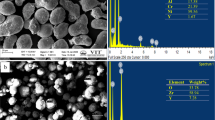

Failure in turbine blades can affect the safety and performance of the gas turbine engine. Results of coating decohesion, erosion and cracking at the first-stage high-pressure (HPT) blade working in gas turbine engine are being reported in this paper. This investigation was carried out for the possibility of various failure mechanisms in the thermal barrier coating exposed to high operating temperature. The blade was made of nickel-based superalloy, having directionally solidified grain structure coated with thermal barrier coatings of yttria-stabilized zirconia with EB-PVD process and platinum-modified aluminum (Pt–Al) bond coat with electro-deposition. The starting point of analysis was apparent coating decohesion close to the leading edge on the suction side of blade. The coating decohesion was found to be widening of interdiffusion zone toward the bond coat at higher operating temperature which could change the composition and induce thermal stresses in the bond coat. The erosion, cracking and decohesion of the coating on the pressure side was also observed during failure investigation. The erosion of the coating was coupled by two factors: one by increase in temperature as demonstrated by change in microstructure of the substrate and second by increase in coating inclination toward the trailing side. As a result of high operating temperature, swelling and thickening of TGO was observed due to outward diffusion of aluminum from the bond coat to form alumina (non-protective oxide) which causes internal stresses that leads to top coat decohesion and cracking. The possibility of hot corrosion was also investigated, and it was found that top coat decohesion did not involve this failure mechanism. Visual inspection, optical microscopy, scanning electron microscopy and energy-dispersive spectroscopy have been used as characterization tools.

Similar content being viewed by others

References

A.M. Kolagar et al., Failure analysis of gas turbine first stage blade made of nickel-based superalloy. Case Stud. Eng. Fail. Anal. 8(Supplement C), 61–68 (2017)

R.G. Wellman, J.R. Nicholls, A review of the erosion of thermal barrier coatings. J. Phys. D Appl. Phys. 40(16), R293 (2007)

B. Gleeson, Thermal barrier coatings for aeroengine applications. J Propul Power 22, 375–383 (2006)

F. Mauget et al., Damage mechanisms in an EB-PVD thermal barrier coating system during TMF and TGMF testing conditions under combustion environment. Int. J. Fatigue 99, 225–234 (2017)

A.G. Evans et al., Mechanisms controlling the durability of thermal barrier coatings. Prog. Mater Sci. 46(5), 505–553 (2001)

W. Ross Earl, K.S. O’hara, Renel’42: a high strength, oxidation resistant DS turbine airfoil alloy, in Superalloys, ed. by R.W. Stusmd, S.D. Antolovich, R.A. MacKay, D.L. Anton, T. Khan, R.D. Kissinger, D.L. Klarstmm (The Minerals, Metals & Materials Society, Pittsburgh, 1992)

T.M. Pollock, Alloy design for aircraft engines. Nat. Mater. 15, 809 (2016)

N.P. Padture, M. Gell, E.H. Jordan, Thermal barrier coatings for gas-turbine engine applications. Science 296(5566), 280–284 (2002)

A.G. Evans, M.Y. He, J.W. Hutchinson, Mechanics-based scaling laws for the durability of thermal barrier coatings. Prog. Mater Sci. 46(3), 249–271 (2001)

V.K. Tolpygo, D.R. Clarke, K.S. Murphy, Oxidation-induced failure of EB-PVD thermal barrier coatings. Surf. Coat. Technol. 146–147, 124–131 (2001)

F.H. Stott, G.C. Wood, Growth and adhesion of oxide scales on Al2O3-forming alloys and coatings. Mater. Sci. Eng. 87, 267–274 (1987)

M.J. Stiger, et al., Accelerated durability testing of coatings for gas turbines. In Elevated Temperature Coatings: Science and Technology IV, ed. by N.B. Dahotre, J. M. Hampikian, J.E. Morral (Wiley, 2003), pp. 1–14. https://doi.org/10.1002/9781118787694.ch1.

M.J. Pomeroy, Coatings for gas turbine materials and long term stability issues. Mater. Des. 26(3), 223–231 (2005)

S. Darzens et al., Observations and analysis of the influence of phase transformations on the instability of the thermally grown oxide in a thermal barrier system. Metall. Mater. Trans. A 34(3), 511–522 (2003)

R. Darolia, Bond coat for a thermal barrier coating system. Google Patents (2000)

E.A.G. Shillington, D.R. Clarke, Spalling failure of a thermal barrier coating associated with aluminum depletion in the bond-coat. Acta Mater. 47(4), 1297–1305 (1999)

Acknowledgments

The authors would like to acknowledge Dr. Daniele de Felicis for his cooperation and guide in characterization activities. All the measurements and characterization activities were carried out at the “Inter-Departmental Laboratory of Electron Microscopy” (LIME), University ROMA TRE (http://www.lime.uniroma3.it).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, R., Shehbaz, T. & Bemporad, E. Investigation on Failure in Thermal Barrier Coatings on Gas Turbine First-Stage Rotor Blade. J Fail. Anal. and Preven. 18, 1062–1072 (2018). https://doi.org/10.1007/s11668-018-0530-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0530-5